- News

- Reviews

- Bikes

- Accessories

- Accessories - misc

- Computer mounts

- Bags

- Bar ends

- Bike bags & cases

- Bottle cages

- Bottles

- Cameras

- Car racks

- Child seats

- Computers

- Glasses

- GPS units

- Helmets

- Lights - front

- Lights - rear

- Lights - sets

- Locks

- Mirrors

- Mudguards

- Racks

- Pumps & CO2 inflators

- Puncture kits

- Reflectives

- Smart watches

- Stands and racks

- Trailers

- Clothing

- Components

- Bar tape & grips

- Bottom brackets

- Brake & gear cables

- Brake & STI levers

- Brake pads & spares

- Brakes

- Cassettes & freewheels

- Chains

- Chainsets & chainrings

- Derailleurs - front

- Derailleurs - rear

- Forks

- Gear levers & shifters

- Groupsets

- Handlebars & extensions

- Headsets

- Hubs

- Inner tubes

- Pedals

- Quick releases & skewers

- Saddles

- Seatposts

- Stems

- Wheels

- Tyres

- Health, fitness and nutrition

- Tools and workshop

- Miscellaneous

- Tubeless valves

- Buyers Guides

- Features

- Forum

- Recommends

- Podcast

How to trim a carbon fibre steerer tube 04

How to trim a carbon fibre steerer tube 04How to trim a carbon fibre steerer tube in 5 easy steps

You'll need to trim your fork steerer if you're fitting a new fork, building up a bike from a frame, or have just decided you really don't need that spare inch that's above the stem. Here's how.

Carbon is the go-to material when you're looking for strength, rigidity and light weight. Those happen to be the exact attributes required of a road bike fork. All-carbon forks used to be the preserve of high-end bikes, with aluminium steerers on entry-level models, but even sub-£1,000 bikes are now coming with carbon steerers. Whether a steerers is alloy or carbon the method for trimming it is broadly the same.

Our guide below shows you what we believe is the best method to trim a carbon fibre steerer. We've included a list of the tools and materials that you will need to complete the job and in some cases where you can buy them. If there are others that you prefer then feel free to let everybody know in the comments.

Health warning

Because the fibres are so thin, the dust produced by cutting and filing carbon fibre composites contains very, very tiny carbon particles. These can irritate the lungs and skin. You should therefore wear a well-fitted face mask to avoid inhaling them, use gloves, and keep skin covered that might be exposed. You should also work in a well-ventilated space away from electrical equipment. Carbon fibre is conductive; you don't want it in your favourite mp3 player or fan heater.

Tools & Materials

Carbon specific hacksaw blade

Steerer tube cutting guide

Tape measure

Masking tape (not pictured)

Step 1: measure, measure and measure

The first thing you need to do is determine exactly how much of the steerer you need. Now, it's common, in the heat of the moment of getting a flash new fork, to see yourself all flat backed and aero, slicing the wind like Cavendish in the last fifty meters of a sprint.

It's tempting to slam the stem on to the headset top cap to get that position, because it looks neat, but cutting your steerer as short as possible can cause issues if you later realise that you're not Cav, on account of how you can't touch your toes and all.

You can't stick the off-cut back on. Better to be honest with yourself. It's less embarrassing and cheaper in the long run.

In short, it's better to have and not need steerer tube, than to need and not have.

I measured up for a fairly flat FSA K-Force stem, fully slammed. However, I left myself an extra inch and a half just in case. Just as well, because in the end, after fifty miles of running in, I switched to a shorter, taller Truvativ T40 stem with a 5mm spacer under it. Had I chopped just for the FSA stem in flat mode, I'd have been stuffed.

Measure, re-measure, check, re-measure again, check again. Put it back in the frame, re-measure. Be honest. Measure a last time. You're now thoroughly ready to chop 45-quid's-worth of carbon from your fork's steerer tube.

Step 2: Mark the steerer

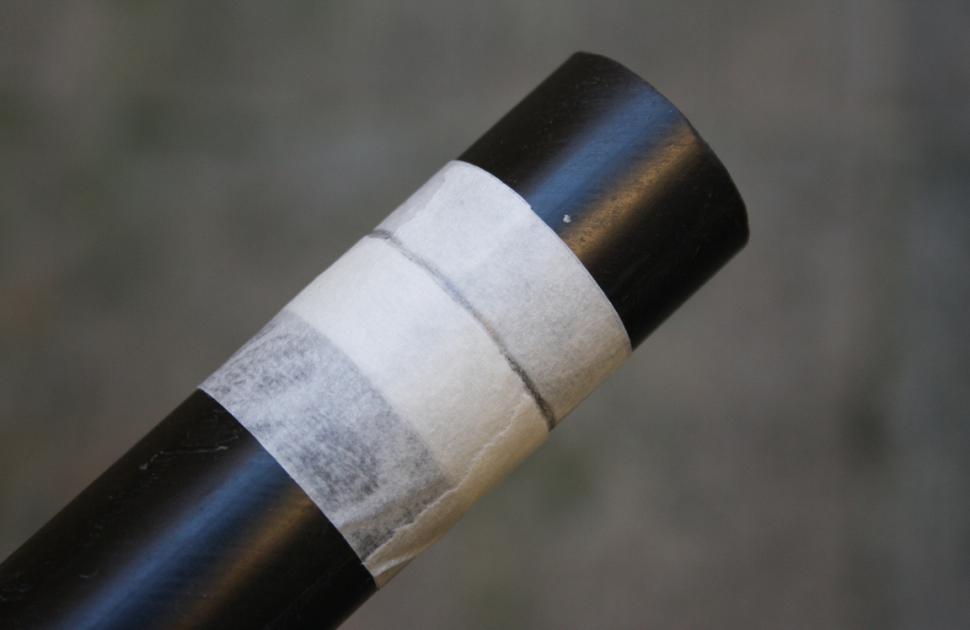

When you've made the final measurement, mark the spot with a wrap of masking tape. This will help ensure the edges of the steerer do not fray during the cutting process (remember carbon fibre is just posh cloth and glue). I make the wrap exactly centered over the cut mark and mark it with a pencil. I then put another wrap to one side with the edge right on the cut line, for no good reason other than habit.

We are using an adjustable saw blade guide. This particular model from Park Tool has a regular slot on the right for alloy steerers (which would use a narrower conventional hacksaw blade). We are using a specific carbon fiber cutting blade which is wider than the toothed version for cutting alloy - hence the wider slot on the left, which is the one we'll be using.

Step 3: Fit the saw guide

Slide the steerer tube into the cutting guide and look down into the cutting slots to see the pencil cut line. Line the pencil mark up directly with the wide slot.

When you've got the cut line lined up, tighten the clamp. The clamp has rubber shoulders, so it won't hurt the steerer tube when done up tight. You want it fairly tight because it mustn't slip.

This is a the carbon specific hacksaw blade. Instead of classic hacksaw jagged teeth, the blade is coated with a fine coating of cutting grit. You can get away with cutting your carbon steerer tube with a conventional blade, but it's not ideal.

Step 4: Cut the steerer

Ideally you'd hold the cutting guide clamp in a bench vise. However, the cutting guide precisely controlling blade position means its technically possible to get away without a vise. I don't have a vise at home and manage happily with the guide alone.

Step 5: Tidy the end

Because the cutting guide keeps the blade so well centred, the finished cut will be pretty well ready to go. It's good form to use a fine file to radius the outer edge and ensure there are no burrs that will catch on the stem and headset internals when you come to fit it. Only do what's necessary and remember carbon dust is nasty stuff. Hoover it up when you're done.

The finished item. The steerer is now the right length and cleanly trimmed and finished.

Latest Comments

- Rendel Harris 9 min 13 sec ago

Care to comment on the fact that according to Mr.O'Connell and an external road safety company's data there have only been three cyclist Personal...

- Hirsute 30 min 13 sec ago

He's just a pathetic troll. Please ignore.

- slc 1 hour 11 min ago

Some locals (apart from road.cc regulars) like the scheme. Admittedly in the Beaufort Rd section where the carrot (end of what was pretty...

- S.E. 15 hours 16 min ago

My guess is that they sell mainly on the German market - feel free to correct me. That might explain why they are not "pushing" their products,...

- ktache 15 hours 41 min ago

Now Emily Chappell really liked the Lezyne , I have the HV version, good, but I find the handle uncomfortable in use. I've often wondered about the...

- biking59boomer 14 hours 48 min ago

What about this one!? Taken in Cardiff Civic Centre 1939

- Muddy Ford 15 hours 51 min ago

Charlie Alliston got 18mths and is the reference case (because there are so few cases) for all campaigns by anti-cyclists that 'cyclists are not...

- belugabob 16 hours 53 min ago

My local football practice pitches (all weather, in a fenced off area, are regularly the scene of inconsiderate parking, with vehicles blocking the...

- Spangly Shiny 17 hours 18 min ago

Assos ASOS anyone?

- chrisonabike 17 hours 31 min ago

Replace them all with Bromptons and they'd take up zero space within days or even hours, as they are all relocated elsewhere. To eBay or possibly...

Add new comment

33 comments

Fine I'll leave it be then! Cheers

I had my carbon stem done by the local bike shop a month ago but he's left 5mm on the top of the stem. Is there a reason for that? Safer, or easier for the top cap to keep pressure on the stem or something?

Asthetically I'd prefer the stem like this, (random Google images picture)

http://65.media.tumblr.com/tumblr_lz5jeoRHXk1qaythmo1_1280.jpg

mine's more like this

https://encrypted-tbn2.gstatic.com/images?q=tbn:ANd9GcQ9cJQKqQrawGzNP4fW...

Can it be cut again, or is trimming off a little bit more risky for any reason? Maybe different stems need more length to attach to for example?

If the steerer tube ends level with the top of the stem, the clamping force is too close to the end of the tube and you affect it's structural integrity. That is why there should be a 5mm spacer on top of the stem - that way the clamping force is distributed properly around the steerer tube. Whist a top cap sitting immediately on top of the stem might look cool, it's potentially dangerous.

Pages