- News

- Reviews

- Bikes

- Components

- Bar tape & grips

- Bottom brackets

- Brake & gear cables

- Brake & STI levers

- Brake pads & spares

- Brakes

- Cassettes & freewheels

- Chains

- Chainsets & chainrings

- Derailleurs - front

- Derailleurs - rear

- Forks

- Gear levers & shifters

- Groupsets

- Handlebars & extensions

- Headsets

- Hubs

- Inner tubes

- Pedals

- Quick releases & skewers

- Saddles

- Seatposts

- Stems

- Wheels

- Tyres

- Tubeless valves

- Accessories

- Accessories - misc

- Computer mounts

- Bags

- Bar ends

- Bike bags & cases

- Bottle cages

- Bottles

- Cameras

- Car racks

- Child seats

- Computers

- Glasses

- GPS units

- Helmets

- Lights - front

- Lights - rear

- Lights - sets

- Locks

- Mirrors

- Mudguards

- Racks

- Pumps & CO2 inflators

- Puncture kits

- Reflectives

- Smart watches

- Stands and racks

- Trailers

- Clothing

- Health, fitness and nutrition

- Tools and workshop

- Miscellaneous

- Buyers Guides

- Features

- Forum

- Recommends

- Podcast

feature

Hunt - Bike in tunnel wheels spinning - 1.jpg

Hunt - Bike in tunnel wheels spinning - 1.jpgReinventing the (aero disc-specific) wheel with Hunt - Pt I

We’re at the wind tunnel and Hunt is trying to reinvent the wheel. Well, to be more specific, Hunt is trying to invent a new type of wheel: a disc-specific aero wheel for 28mm tubeless tyres. The results traced out on the computer screens show that it’s all going very well.

Hunt, set up by brothers Tom and Peter Marchment in West Sussex in 2015, approached road.cc at the end of last year and said that it intended to develop a new wheelset, and asked whether we’d be interested in following the process from concept stage right through to final production. We thought about it and decided it sounded interesting, so that’s what we’re going to do. We’re not sure how many articles this will involve – to some extent that will depend on how things go – but when we have enough material to produce the next instalment we’ll crack on with it.

What’s the aim?

“We’re designing an aero wheel for people who recognise the benefits of 28mm tyres, tubeless technology and disc brakes,” says Tom Marchment (below).

“We’re starting from the standpoint that many of us want the increased grip, lower rolling resistance, greater puncture protection, lower pressures and improved ride quality that you can get with wider tubeless tyres.

“We’re not saying we’re going to make a more aerodynamic wheel than a time trial model designed around a 21mm or a 23mm tyre, but we’re starting with a 28mm tubeless tyre – the Schwalbe Pro One, the industry-leading road tubeless tyre – and designing an aerodynamic wheel for everything from short, fast road rides to sportives and longer events.

“We don’t believe that anyone else has actually designed aero wheels for this area of the market or applied a lot of investment and thought into this type of product before.”

It’s an interesting idea. Ever more road bikes are designed for disc brakes these days, including aero road bikes, and ever more people are switching to 28mm tyres. We’ve heard that some tyre brands are selling more 28s than 23s these days. That’s certainly the direction that things are going.

Developing prototypes

Okay, so where the hell do you start? Hunt’s first major objective was to take a bunch of prototypes to the wind tunnel to see how they performed against one another and against existing wheels from rival manufacturers and the current Hunt line-up.

How do you develop those prototypes? Hunt has recently taken on Italian aerodynamics specialist Luisa Grappone (above) as Engineering and Product Manager. Having previously worked at Campagnolo for four years and with 3T prior to that, Luisa has lots of experience in the bike industry and already had plenty of ideas on areas to explore.

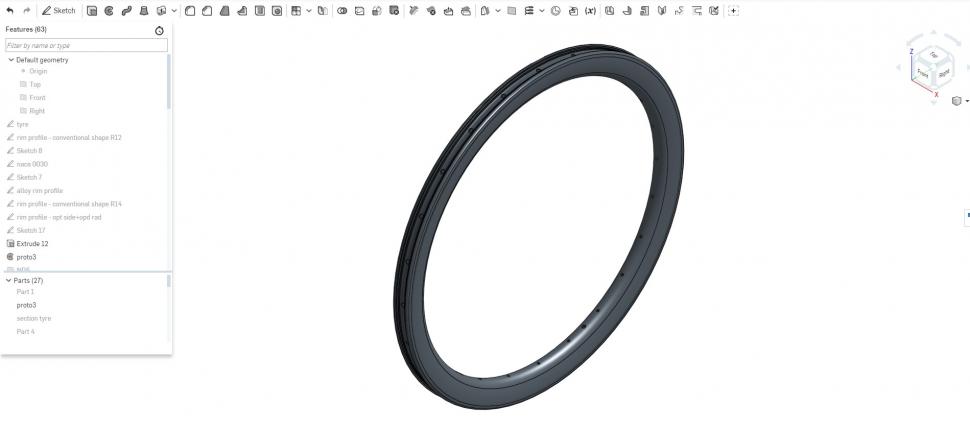

“We had in mind some shape configurations and an idea of how wide and deep we wanted the rim to be, and I already had an idea of the importance of the area where the spoke nipples are,” says Luisa.

“I was working on getting some different shapes which could better interconnect the upper and lower parts of the rim. I already knew, for example, that a bigger radius at the spoke side was better, but I started with some conventional rims – not so wide, not so big and bulgy – and from there looked at how wide the rim could be in that area. So what I did was define two or three different radii for that area and two different widths, and then combined the shapes.

“Many companies are now doing NACA-type designs (NACA is the National Advisory Committee for Aeronautics), but the NACA shape cannot really be applied to this very wide aero profile because it has a very V-shaped tail and we know that in the cycling industry a V-shaped rim doesn’t work.

“I was trying to make a NACA profile and attempting to define the interaction at the upper part – where the NACA is bigger and rounded – in order to get a better combination of the tyre and the rim. I wanted to see what could be done in the upper part, not at the V-shaped side.”

Luisa also had to make sure that her ideas didn’t infringe existing patents, and eventually came up with five different designs. Understandably, Hunt doesn’t want to give specifics about the dimensions of these designs at this stage.

The company considered using CFD (computational fluid dynamics) software to get an idea of the best rim profile but decided to try 3D-printing prototypes for wind tunnel testing instead.

“We built the prototype, put the tyre on and pumped it up step by step, starting at 20psi because we were afraid it might break,” says Luisa. “Although we eventually did our testing at 60psi, we went up to 70psi without any problems, so we knew that the prototype concept worked.”

The prototype rims are solid so they’re heavy and are in no way rideable, but that’s not the point. It’s the shape that matters in the wind tunnel so the key point is that the prototypes can be built up into complete wheels with hubs and spokes and put on a bike.

One caveat to bear in mind is that the bead hooks of the Hunt prototypes had to be made chunkier than they would be on a finished wheel in order to hold inflated tyres in place. This means that the transition from rim to tyre isn’t as smooth as it would otherwise be and the prototypes’ wind tunnel figures would be likely to take a slight hit as a result.

The development of the five prototypes might sound relatively straightforward but it takes weeks. There’s no magic button on your computer that automatically creates the perfect rim profile for a 28mm tyre.

At this stage Hunt isn’t especially concerned about how a particular rim shape can eventually be produced or even about its weight. That comes later. All that matters here is getting a rim shape that works aerodynamically.

Heading to the wind tunnel

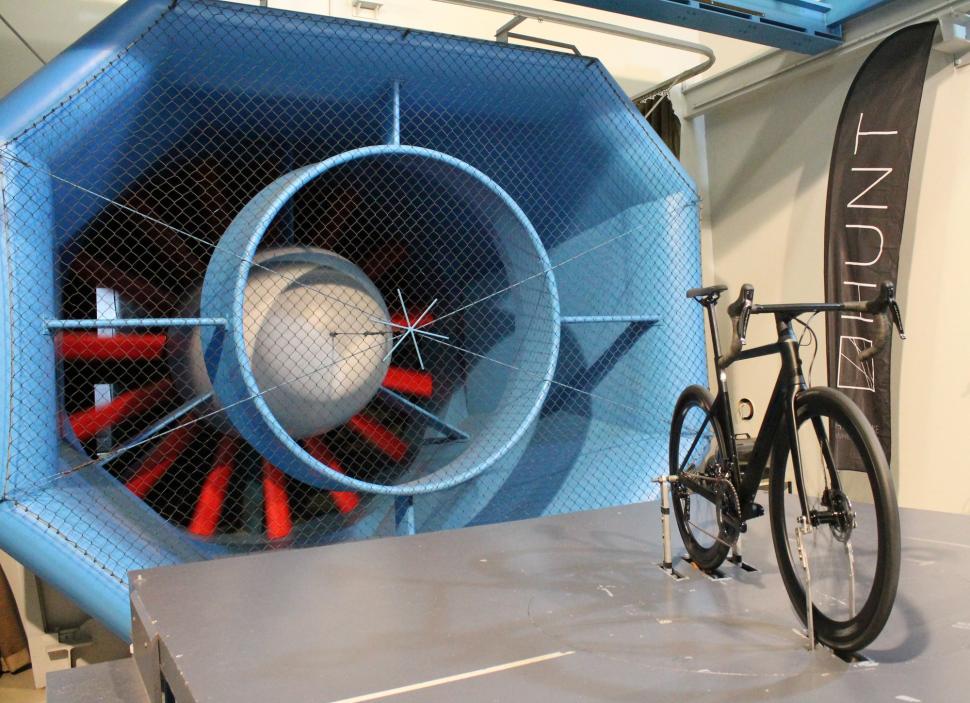

Hunt decided to use the GST (Gesellschaft für Strömungsmeßtechnik) wind-tunnel in Immenstaad am Bodensee, Germany because it is set up for cycling applications and Luisa has used it in previous jobs. This is the same wind tunnel that Dave visited with Swiss Side a couple of years ago.

What’s the wind tunnel like? It’s a big room with a big fan – a humungous fan – built into one end, separated off by chainlink fencing. When the fan spins it draws in air from outside so, being January, it’s pretty cold in there.

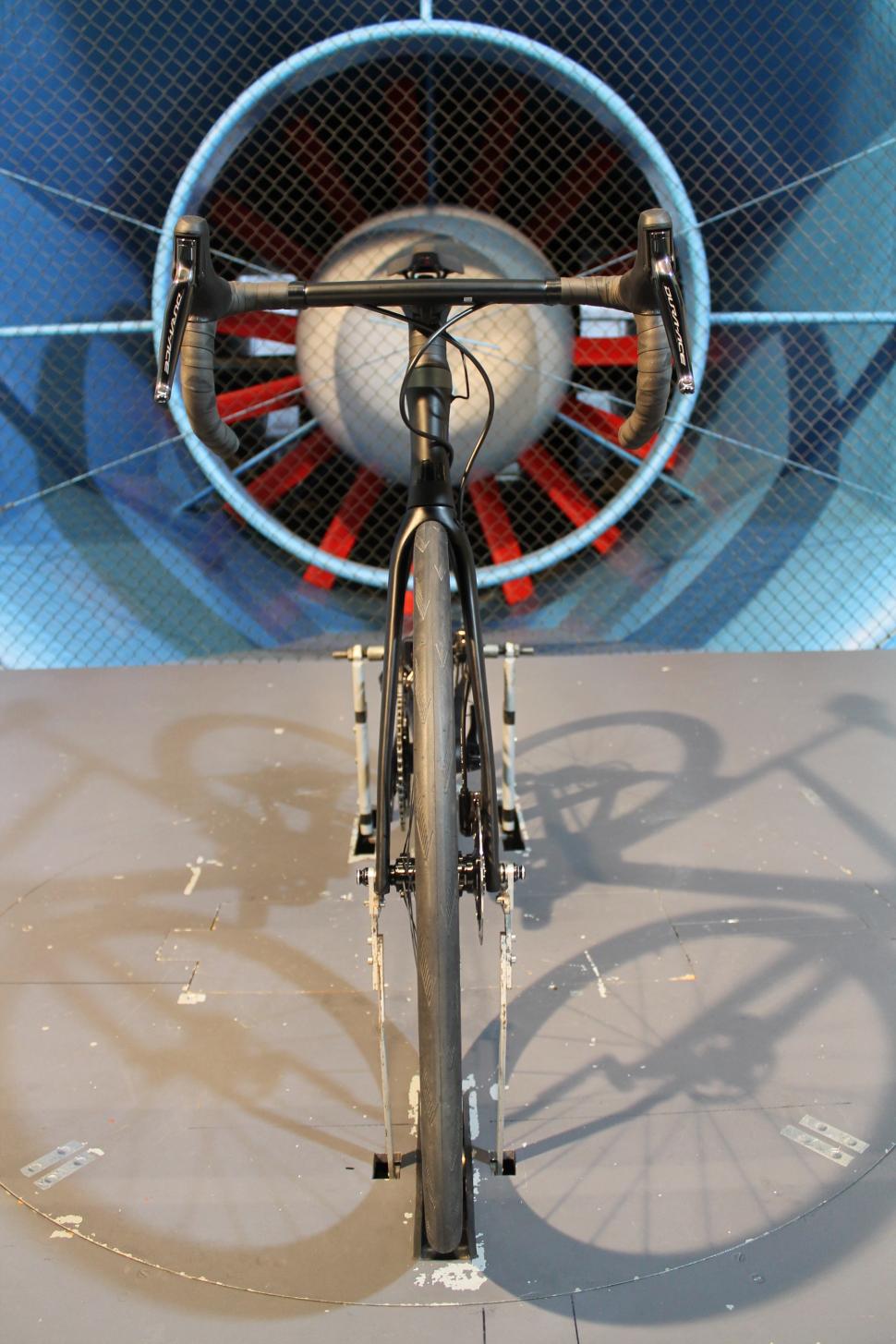

The bike sits on a platform in the middle of the wind tunnel. The tyres rest on rollers that spin the wheels up to the chosen speed of 45km/h (28mph), the same as the wind speed. A turntable built into the platform slowly alters the position of the bike so that drag can be measured from an angle of 20° on the driveside right through to 20° on the non-driveside. A complete run takes a couple of minutes, maybe. Not long.

You don’t stay in the wind tunnel while it’s working, you go into the office next door where you can watch through a big window. There are dials and displays everywhere – it all looks a bit Cold War – and you’re not allowed to put your coffee on the control desk or you’ll get told off by Ernst Pfeiffer who runs this place.

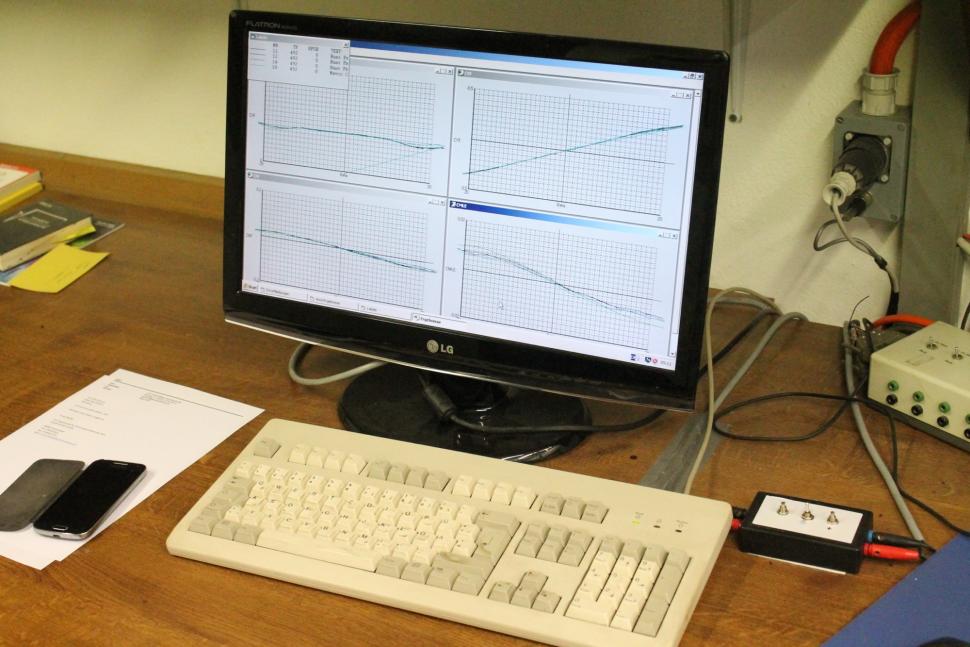

Measurements are displayed on screen in real time. You can lay the results of the current test over those of a previous run for direct comparison and, of course, everything is recorded for analysis later on. If you want numbers you’ve come to the right place.

As mentioned, Hunt is here to test five of its own prototypes. It’s also measuring existing models in its lineup and rival disc brake wheels:

• Zipp 303 NSW (45mm deep)

• Stan’s NoTubes ZTR Avion (40.6mm deep)

• DT Swiss ERC 1100 Dicut 47 (47mm deep)

• Mavic Cosmic Pro Carbon SL UST Disc (40mm deep)

• Enve SES 4.5 AR (49mm deep)

• Enve SES 3.4 (38mm deep)

Hunt has decided to use a Canyon Aeroad road bike in the wind tunnel and to swap just the front wheel from one run to the next.

“We were initially thinking of making a complete set of each prototype but there was no time,” says Luisa. “Also, when you do a wind tunnel test what really matters is the front part of the bike. The rear wheel of course affects the test but we decided to use one of the best aero wheels on the market, the Enve 4.5, as our reference rear wheel.”

All of the wheels were fitted with a Schwalbe Pro One 28mm tyre. Initially, Hunt was swapping the same tyre from one wheel to the next after each run for consistency, but a control run with a second Schwalbe Pro One 28mm gave exactly the same results meaning that one wheel could be prepared while another was in the wind tunnel. This sped things up considerably.

All wheels were fitted with a SRAM 140mm disc rotor because, apart from their methods of fixing, the six bolt and the centrelock versions of that model are identical.

Testing each wheel/tyre combo in the wind tunnel is relatively straightforward. Well, the actual doing bit is relatively straightforward, the tech behind it is anything but. The tyre goes on the wheel, it’s pumped up to 60psi and the width is measured with vernier callipers. The wheel is fitted to the bike in the wind tunnel, you fire it up and get the results. Next!

That’s the way you want it to be, of course. You want the maximum standardisation and minimal opportunity for variation or errors could creep in.

Results

The headline news is that Hunt is very pleased with the results from the wind tunnel.

First off, it’s worth saying that Hunt wasn’t particularly stressed about whether its wheels came out on top.

“These are prototypes so it would be nice if they came out ahead of the competitor wheels but it’s not essential,” said Tom Marchment.

Why so relaxed? Because, as mentioned, the large bead hook of Hunt’s prototypes puts them at a disadvantage versus the competition, and production versions of these wheels, made with the correct materials, wouldn’t have the same issue.

Second, Hunt isn’t planning to rely solely on aerodynamics to sell whatever wheels it eventually brings to market. Hunt could still be on to a winner if it developed a wheel that was a little less aerodynamically efficient than a rival but a whole lot cheaper, for example.

The wind tunnel spits out loads and loads of figures, the most important of them relating to the drag coefficient and the steering moment, but what do you do with those figures? You might imagine that you plot them on to some sort of graph and the best aero performance is immediately obvious. As usual, it’s not as easy as that.

Why? Okay, if the drag figures for one wheel are lower than those for another wheel at every angle from +20° to -20° (41 points; don’t forget to include zero) you can reasonably say that wheel is more aerodynamically efficient.

But what if one wheel has lower drag than another at some angles and higher drag at other angles? You can’t just count up the number of lower figures and say that one wheel wins by 21 points to 20, say, because all angles aren’t of equal importance.

The yaw, the relative wind angle, results from the actual direction and speed of the wind that you’re riding in, and the speed at which you’re moving. If you’re out for a ride and there’s no wind at all – the air is totally still – the apparent wind, caused solely by your movement, is going to come from straight ahead. Simple.

The faster you ride, the higher the apparent wind caused by your movement. Again, that’s pretty obvious. Follow that through and it means that in the same conditions a faster rider will be riding at a lower average yaw (the effective wind will be closer to head-on), so for that particular rider a wheel’s performance at lower yaw angles will be more relevant than for a slower rider.

We already know that riders travelling at higher speeds don’t typically spend much time with the yaw angle at 20°, they spend far, far more time with the yaw below 10°, so it would be mad to treat drag at 20° as if it was as important as drag at 7°, for instance.

The point is, the wind tunnel might give you loads of figures but you then need to interpret those figures and there’s no standard way of doing that. That’s why pretty much every new aero road bike and set of aero wheels can claim to have the lowest drag out there. Each manufacturer can choose to weight their wind tunnel (or CFD) data as they see fit and – what a surprise – they see fit to give greatest weight to the angles where their product performs best.

“Ah,” you say, “but what about wind averaged drag?”

This is a weighting given to aero data across a range of angles, the idea being that you end up with a single, directly comparable figure. Again, though, a wind averaged drag will depend on the speed you’re doing and the conditions in which you’re riding and there’s no calculation for achieving such a figure that’s accepted across the bike industry.

Hunt says it would be happy to use another brand’s method of calculating wind averaged drag in order to give consumers useful data upon which to base their buying decisions, as long as that method made sense, but other brands aren’t necessarily going to reveal their methods.

Confused? The basic point is that developing an aero wheel doesn’t just involve taking a bunch of ideas to the wind tunnel and – hey presto! – you find out which is most efficient and then go away and make it.

So what did we find out?

“The data confirms that in this configuration [with a 28mm Schwalbe Pro One tyre] our Prototype 3 is better than the competitors,” says Luisa. “We must say that we are talking about very small differences. Enve, Zipp, DT Swiss and our prototype are very close to each other.

“I did all the calculations of power and time savings and in some configurations our wheel is better than the Enve 4.5, for instance, and in some we are a fraction slower, so we can say that we are as good as Enve in terms of aerodynamics.

“The wind tunnel confirmed the design we had in mind. Going for a very wide rim and a very big radius at the nipple side, it works. We have a really good wheel with aerodynamics that are comparable with the competitors’.”

Hunt will probably publish the wind tunnel findings to back up this claim further down the line.

Success with the prototype is good news but it’s only the beginning of the process of getting a wheel to market, which is why we’ll be back soon to tell you what Hunt has decided to do next.

Note: Hunt paid for my EasyJet ticket to Germany and for my hotel room for the night. Hunt doesn’t have any control over what’s written here. If the project doesn’t go to plan in any way, we’ll be telling you about that too.

Mat has been in cycling media since 1996, on titles including BikeRadar, Total Bike, Total Mountain Bike, What Mountain Bike and Mountain Biking UK, and he has been editor of 220 Triathlon and Cycling Plus. Mat has been road.cc technical editor for over a decade, testing bikes, fettling the latest kit, and trying out the most up-to-the-minute clothing. He has won his category in Ironman UK 70.3 and finished on the podium in both marathons he has run. Mat is a Cambridge graduate who did a post-grad in magazine journalism, and he is a winner of the Cycling Media Award for Specialist Online Writer. Now over 50, he's riding road and gravel bikes most days for fun and fitness rather than training for competitions.

Latest Comments

- pockstone 2 sec ago

Meanwhile...in other Cornish news, cyclists and their problems: https://www.cornwalllive.com/news/cornwall-news/worlds-gone-mad-litter-p...

- thax1 7 min 3 sec ago

Have no fear Laz. Pop over there and One can still share a happy wave with a Maga aero helmet wearer. Then bask in the bittersweet knowledge that...

- Car Delenda Est 9 min 31 sec ago

No. A publicly funded body abusing its power and artificially shaping UK politics.

- SecretSam 49 min 9 sec ago

just to be clear - do we know for sure that the humpy-pumpy system was to blame? Lucky he was on his own, imagine the carnage if he'd been in the...

- Rome73 49 min 37 sec ago

https://thebikeproject.co.uk/ this project in London does the same - if anyone has any unused bikes they would like to donate.

- ktache 9 hours 42 min ago

Quest are showing the Paris Roubaix highlights at 11 both days.

- chrisonabike 10 hours 26 min ago

Pretty sure a lot of that "more space for motor vehicles" was because fewer motor vehicles (also marginally "smaller motor vehicles")....

- thax1 11 hours 51 min ago

Cycliq certainly seemed to let a lot of people down in the early days. I held off until the 12 Sport came out, but have been impressed....

- ktache 11 hours 53 min ago

My better half seems to like giving me pressies of Rapha clothing. I am wearing their casual hoodie right now, and very nice it is too. First off...

- thax1 12 hours 3 min ago

Push on through foot numbness and you then arrive at agonising foot cramp....

Add new comment

31 comments

Very interesting. Looking forward to the further adventures of Hunt Wheels.

Pages