- News

- Reviews

- Bikes

- Components

- Bar tape & grips

- Bottom brackets

- Brake & gear cables

- Brake & STI levers

- Brake pads & spares

- Brakes

- Cassettes & freewheels

- Chains

- Chainsets & chainrings

- Derailleurs - front

- Derailleurs - rear

- Forks

- Gear levers & shifters

- Groupsets

- Handlebars & extensions

- Headsets

- Hubs

- Inner tubes

- Pedals

- Quick releases & skewers

- Saddles

- Seatposts

- Stems

- Wheels

- Tyres

- Tubeless valves

- Accessories

- Accessories - misc

- Computer mounts

- Bags

- Bar ends

- Bike bags & cases

- Bottle cages

- Bottles

- Cameras

- Car racks

- Child seats

- Computers

- Glasses

- GPS units

- Helmets

- Lights - front

- Lights - rear

- Lights - sets

- Locks

- Mirrors

- Mudguards

- Racks

- Pumps & CO2 inflators

- Puncture kits

- Reflectives

- Smart watches

- Stands and racks

- Trailers

- Clothing

- Health, fitness and nutrition

- Tools and workshop

- Miscellaneous

- Buyers Guides

- Features

- Forum

- Recommends

- Podcast

feature

Hunt - Bike in tunnel wheels spinning - 1.jpg

Hunt - Bike in tunnel wheels spinning - 1.jpgReinventing the (aero disc-specific) wheel with Hunt - Pt I

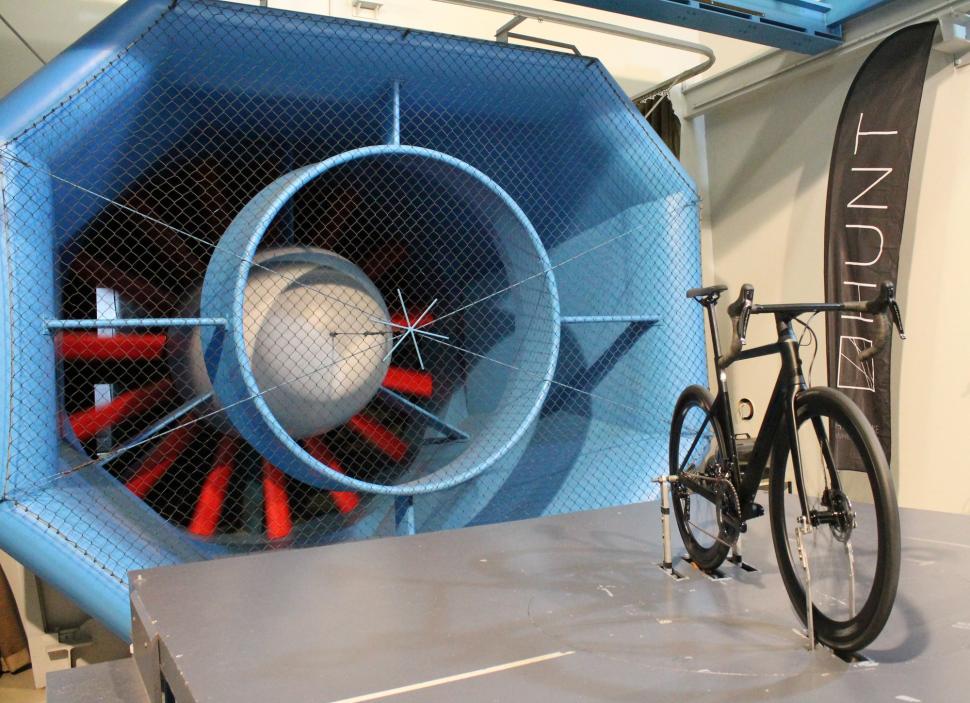

We’re at the wind tunnel and Hunt is trying to reinvent the wheel. Well, to be more specific, Hunt is trying to invent a new type of wheel: a disc-specific aero wheel for 28mm tubeless tyres. The results traced out on the computer screens show that it’s all going very well.

Hunt, set up by brothers Tom and Peter Marchment in West Sussex in 2015, approached road.cc at the end of last year and said that it intended to develop a new wheelset, and asked whether we’d be interested in following the process from concept stage right through to final production. We thought about it and decided it sounded interesting, so that’s what we’re going to do. We’re not sure how many articles this will involve – to some extent that will depend on how things go – but when we have enough material to produce the next instalment we’ll crack on with it.

What’s the aim?

“We’re designing an aero wheel for people who recognise the benefits of 28mm tyres, tubeless technology and disc brakes,” says Tom Marchment (below).

“We’re starting from the standpoint that many of us want the increased grip, lower rolling resistance, greater puncture protection, lower pressures and improved ride quality that you can get with wider tubeless tyres.

“We’re not saying we’re going to make a more aerodynamic wheel than a time trial model designed around a 21mm or a 23mm tyre, but we’re starting with a 28mm tubeless tyre – the Schwalbe Pro One, the industry-leading road tubeless tyre – and designing an aerodynamic wheel for everything from short, fast road rides to sportives and longer events.

“We don’t believe that anyone else has actually designed aero wheels for this area of the market or applied a lot of investment and thought into this type of product before.”

It’s an interesting idea. Ever more road bikes are designed for disc brakes these days, including aero road bikes, and ever more people are switching to 28mm tyres. We’ve heard that some tyre brands are selling more 28s than 23s these days. That’s certainly the direction that things are going.

Developing prototypes

Okay, so where the hell do you start? Hunt’s first major objective was to take a bunch of prototypes to the wind tunnel to see how they performed against one another and against existing wheels from rival manufacturers and the current Hunt line-up.

How do you develop those prototypes? Hunt has recently taken on Italian aerodynamics specialist Luisa Grappone (above) as Engineering and Product Manager. Having previously worked at Campagnolo for four years and with 3T prior to that, Luisa has lots of experience in the bike industry and already had plenty of ideas on areas to explore.

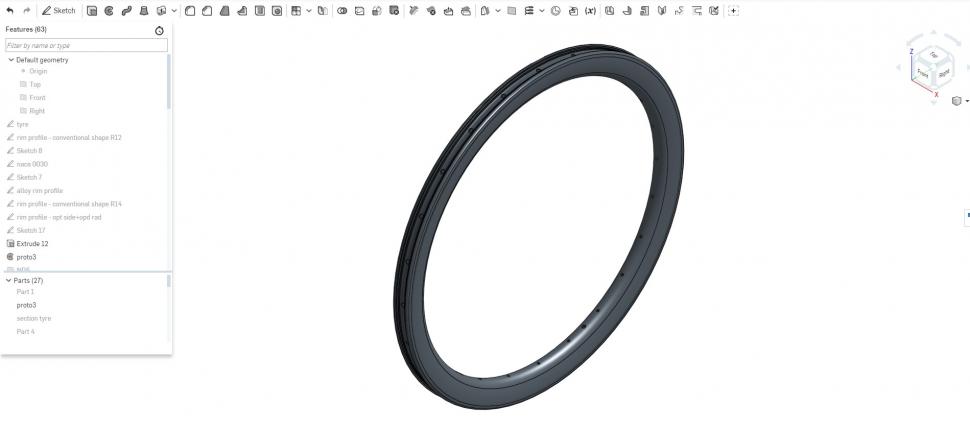

“We had in mind some shape configurations and an idea of how wide and deep we wanted the rim to be, and I already had an idea of the importance of the area where the spoke nipples are,” says Luisa.

“I was working on getting some different shapes which could better interconnect the upper and lower parts of the rim. I already knew, for example, that a bigger radius at the spoke side was better, but I started with some conventional rims – not so wide, not so big and bulgy – and from there looked at how wide the rim could be in that area. So what I did was define two or three different radii for that area and two different widths, and then combined the shapes.

“Many companies are now doing NACA-type designs (NACA is the National Advisory Committee for Aeronautics), but the NACA shape cannot really be applied to this very wide aero profile because it has a very V-shaped tail and we know that in the cycling industry a V-shaped rim doesn’t work.

“I was trying to make a NACA profile and attempting to define the interaction at the upper part – where the NACA is bigger and rounded – in order to get a better combination of the tyre and the rim. I wanted to see what could be done in the upper part, not at the V-shaped side.”

Luisa also had to make sure that her ideas didn’t infringe existing patents, and eventually came up with five different designs. Understandably, Hunt doesn’t want to give specifics about the dimensions of these designs at this stage.

The company considered using CFD (computational fluid dynamics) software to get an idea of the best rim profile but decided to try 3D-printing prototypes for wind tunnel testing instead.

“We built the prototype, put the tyre on and pumped it up step by step, starting at 20psi because we were afraid it might break,” says Luisa. “Although we eventually did our testing at 60psi, we went up to 70psi without any problems, so we knew that the prototype concept worked.”

The prototype rims are solid so they’re heavy and are in no way rideable, but that’s not the point. It’s the shape that matters in the wind tunnel so the key point is that the prototypes can be built up into complete wheels with hubs and spokes and put on a bike.

One caveat to bear in mind is that the bead hooks of the Hunt prototypes had to be made chunkier than they would be on a finished wheel in order to hold inflated tyres in place. This means that the transition from rim to tyre isn’t as smooth as it would otherwise be and the prototypes’ wind tunnel figures would be likely to take a slight hit as a result.

The development of the five prototypes might sound relatively straightforward but it takes weeks. There’s no magic button on your computer that automatically creates the perfect rim profile for a 28mm tyre.

At this stage Hunt isn’t especially concerned about how a particular rim shape can eventually be produced or even about its weight. That comes later. All that matters here is getting a rim shape that works aerodynamically.

Heading to the wind tunnel

Hunt decided to use the GST (Gesellschaft für Strömungsmeßtechnik) wind-tunnel in Immenstaad am Bodensee, Germany because it is set up for cycling applications and Luisa has used it in previous jobs. This is the same wind tunnel that Dave visited with Swiss Side a couple of years ago.

What’s the wind tunnel like? It’s a big room with a big fan – a humungous fan – built into one end, separated off by chainlink fencing. When the fan spins it draws in air from outside so, being January, it’s pretty cold in there.

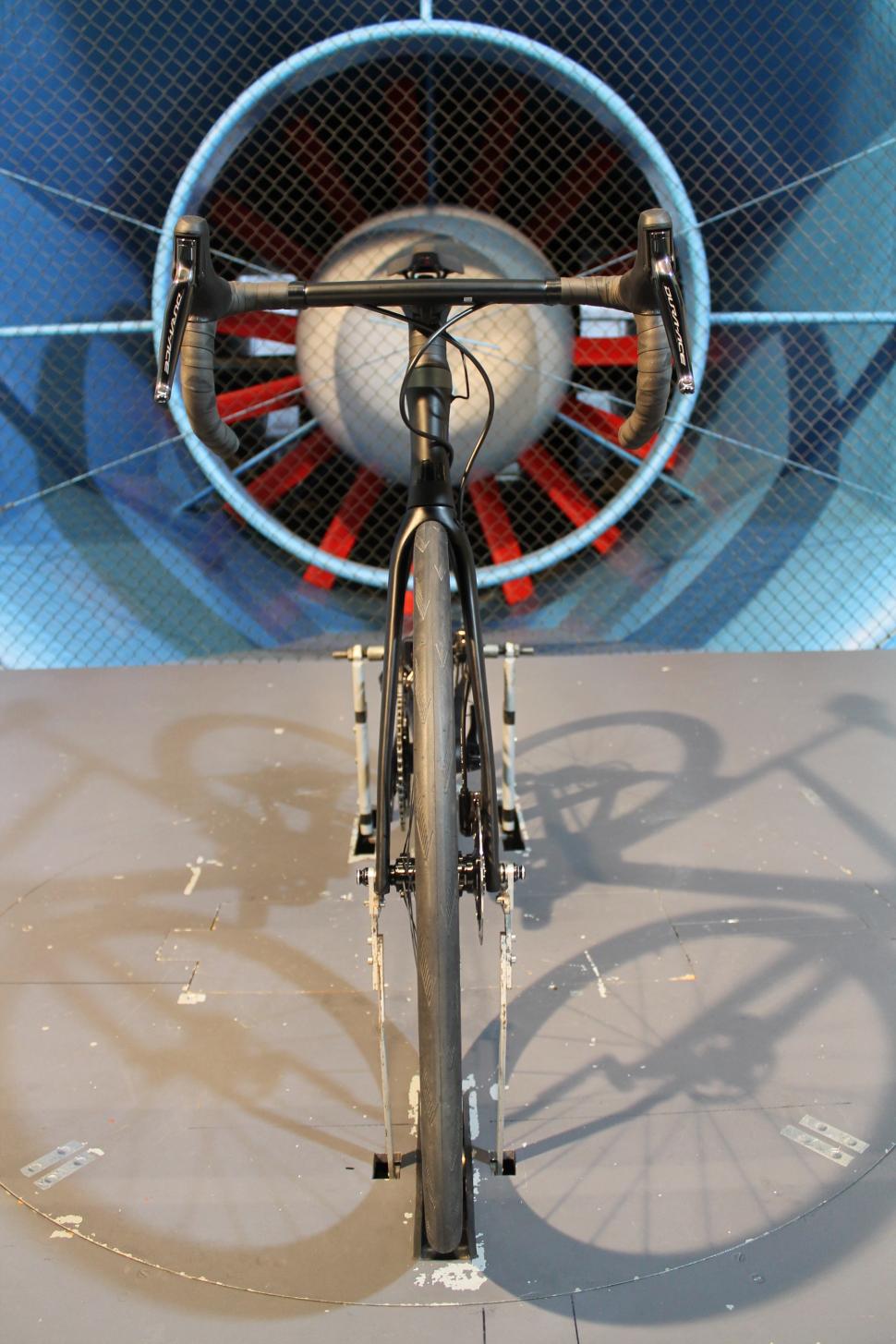

The bike sits on a platform in the middle of the wind tunnel. The tyres rest on rollers that spin the wheels up to the chosen speed of 45km/h (28mph), the same as the wind speed. A turntable built into the platform slowly alters the position of the bike so that drag can be measured from an angle of 20° on the driveside right through to 20° on the non-driveside. A complete run takes a couple of minutes, maybe. Not long.

You don’t stay in the wind tunnel while it’s working, you go into the office next door where you can watch through a big window. There are dials and displays everywhere – it all looks a bit Cold War – and you’re not allowed to put your coffee on the control desk or you’ll get told off by Ernst Pfeiffer who runs this place.

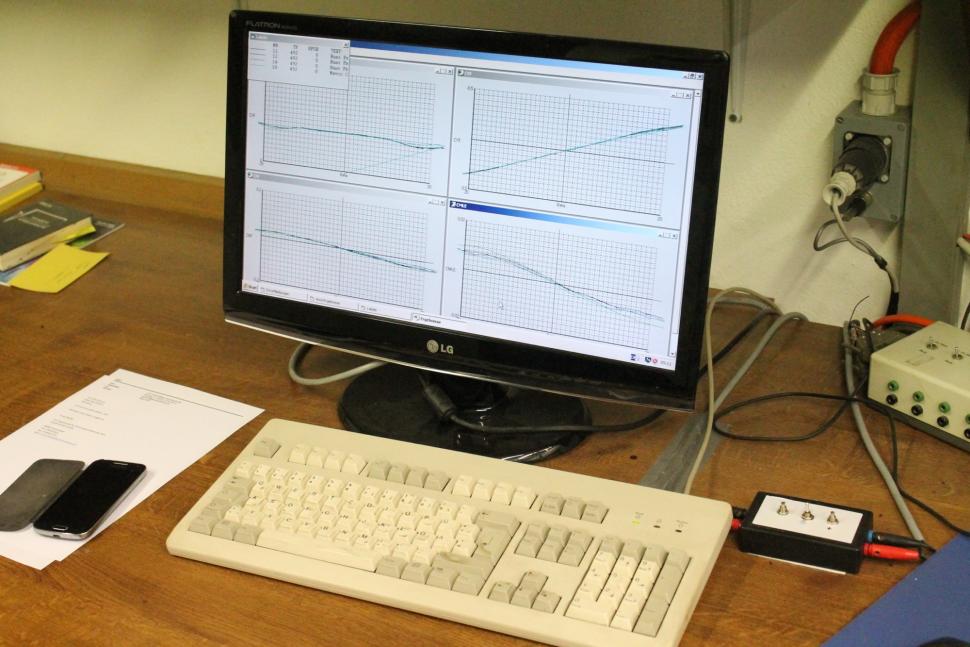

Measurements are displayed on screen in real time. You can lay the results of the current test over those of a previous run for direct comparison and, of course, everything is recorded for analysis later on. If you want numbers you’ve come to the right place.

As mentioned, Hunt is here to test five of its own prototypes. It’s also measuring existing models in its lineup and rival disc brake wheels:

• Zipp 303 NSW (45mm deep)

• Stan’s NoTubes ZTR Avion (40.6mm deep)

• DT Swiss ERC 1100 Dicut 47 (47mm deep)

• Mavic Cosmic Pro Carbon SL UST Disc (40mm deep)

• Enve SES 4.5 AR (49mm deep)

• Enve SES 3.4 (38mm deep)

Hunt has decided to use a Canyon Aeroad road bike in the wind tunnel and to swap just the front wheel from one run to the next.

“We were initially thinking of making a complete set of each prototype but there was no time,” says Luisa. “Also, when you do a wind tunnel test what really matters is the front part of the bike. The rear wheel of course affects the test but we decided to use one of the best aero wheels on the market, the Enve 4.5, as our reference rear wheel.”

All of the wheels were fitted with a Schwalbe Pro One 28mm tyre. Initially, Hunt was swapping the same tyre from one wheel to the next after each run for consistency, but a control run with a second Schwalbe Pro One 28mm gave exactly the same results meaning that one wheel could be prepared while another was in the wind tunnel. This sped things up considerably.

All wheels were fitted with a SRAM 140mm disc rotor because, apart from their methods of fixing, the six bolt and the centrelock versions of that model are identical.

Testing each wheel/tyre combo in the wind tunnel is relatively straightforward. Well, the actual doing bit is relatively straightforward, the tech behind it is anything but. The tyre goes on the wheel, it’s pumped up to 60psi and the width is measured with vernier callipers. The wheel is fitted to the bike in the wind tunnel, you fire it up and get the results. Next!

That’s the way you want it to be, of course. You want the maximum standardisation and minimal opportunity for variation or errors could creep in.

Results

The headline news is that Hunt is very pleased with the results from the wind tunnel.

First off, it’s worth saying that Hunt wasn’t particularly stressed about whether its wheels came out on top.

“These are prototypes so it would be nice if they came out ahead of the competitor wheels but it’s not essential,” said Tom Marchment.

Why so relaxed? Because, as mentioned, the large bead hook of Hunt’s prototypes puts them at a disadvantage versus the competition, and production versions of these wheels, made with the correct materials, wouldn’t have the same issue.

Second, Hunt isn’t planning to rely solely on aerodynamics to sell whatever wheels it eventually brings to market. Hunt could still be on to a winner if it developed a wheel that was a little less aerodynamically efficient than a rival but a whole lot cheaper, for example.

The wind tunnel spits out loads and loads of figures, the most important of them relating to the drag coefficient and the steering moment, but what do you do with those figures? You might imagine that you plot them on to some sort of graph and the best aero performance is immediately obvious. As usual, it’s not as easy as that.

Why? Okay, if the drag figures for one wheel are lower than those for another wheel at every angle from +20° to -20° (41 points; don’t forget to include zero) you can reasonably say that wheel is more aerodynamically efficient.

But what if one wheel has lower drag than another at some angles and higher drag at other angles? You can’t just count up the number of lower figures and say that one wheel wins by 21 points to 20, say, because all angles aren’t of equal importance.

The yaw, the relative wind angle, results from the actual direction and speed of the wind that you’re riding in, and the speed at which you’re moving. If you’re out for a ride and there’s no wind at all – the air is totally still – the apparent wind, caused solely by your movement, is going to come from straight ahead. Simple.

The faster you ride, the higher the apparent wind caused by your movement. Again, that’s pretty obvious. Follow that through and it means that in the same conditions a faster rider will be riding at a lower average yaw (the effective wind will be closer to head-on), so for that particular rider a wheel’s performance at lower yaw angles will be more relevant than for a slower rider.

We already know that riders travelling at higher speeds don’t typically spend much time with the yaw angle at 20°, they spend far, far more time with the yaw below 10°, so it would be mad to treat drag at 20° as if it was as important as drag at 7°, for instance.

The point is, the wind tunnel might give you loads of figures but you then need to interpret those figures and there’s no standard way of doing that. That’s why pretty much every new aero road bike and set of aero wheels can claim to have the lowest drag out there. Each manufacturer can choose to weight their wind tunnel (or CFD) data as they see fit and – what a surprise – they see fit to give greatest weight to the angles where their product performs best.

“Ah,” you say, “but what about wind averaged drag?”

This is a weighting given to aero data across a range of angles, the idea being that you end up with a single, directly comparable figure. Again, though, a wind averaged drag will depend on the speed you’re doing and the conditions in which you’re riding and there’s no calculation for achieving such a figure that’s accepted across the bike industry.

Hunt says it would be happy to use another brand’s method of calculating wind averaged drag in order to give consumers useful data upon which to base their buying decisions, as long as that method made sense, but other brands aren’t necessarily going to reveal their methods.

Confused? The basic point is that developing an aero wheel doesn’t just involve taking a bunch of ideas to the wind tunnel and – hey presto! – you find out which is most efficient and then go away and make it.

So what did we find out?

“The data confirms that in this configuration [with a 28mm Schwalbe Pro One tyre] our Prototype 3 is better than the competitors,” says Luisa. “We must say that we are talking about very small differences. Enve, Zipp, DT Swiss and our prototype are very close to each other.

“I did all the calculations of power and time savings and in some configurations our wheel is better than the Enve 4.5, for instance, and in some we are a fraction slower, so we can say that we are as good as Enve in terms of aerodynamics.

“The wind tunnel confirmed the design we had in mind. Going for a very wide rim and a very big radius at the nipple side, it works. We have a really good wheel with aerodynamics that are comparable with the competitors’.”

Hunt will probably publish the wind tunnel findings to back up this claim further down the line.

Success with the prototype is good news but it’s only the beginning of the process of getting a wheel to market, which is why we’ll be back soon to tell you what Hunt has decided to do next.

Note: Hunt paid for my EasyJet ticket to Germany and for my hotel room for the night. Hunt doesn’t have any control over what’s written here. If the project doesn’t go to plan in any way, we’ll be telling you about that too.

Mat has been in cycling media since 1996, on titles including BikeRadar, Total Bike, Total Mountain Bike, What Mountain Bike and Mountain Biking UK, and he has been editor of 220 Triathlon and Cycling Plus. Mat has been road.cc technical editor for over a decade, testing bikes, fettling the latest kit, and trying out the most up-to-the-minute clothing. He has won his category in Ironman UK 70.3 and finished on the podium in both marathons he has run. Mat is a Cambridge graduate who did a post-grad in magazine journalism, and he is a winner of the Cycling Media Award for Specialist Online Writer. Now over 50, he's riding road and gravel bikes most days for fun and fitness rather than training for competitions.

Latest Comments

- Rendel Harris 21 min 52 sec ago

Absolutely they could have. Tarmac is a petroleum-based product and its surface can be very oily when it's newly laid. This is particularly the...

- ROOTminus1 6 hours 24 min ago

I'm glad the article went into more detail and cleared things up, the headline had me worried that some autonomous building had run rampant and...

- mark1a 6 hours 42 min ago

Still here, just showing a few signs of wear and tear. Hopefully still serviceable for some years to come.

- Secret_squirrel 7 hours 12 min ago

Has he fully recovered though, and will he ever?...

- Rendel Harris 7 hours 27 min ago

How can you know that you are "equally fearful" as "any female cyclist"? There is no possible way of quantifying such emotions and female cyclists...

- chrisonabike 7 hours 59 min ago

I think it would be fairer to blame the moon - as in "my client is a loony".

- Bungle_52 8 hours 22 min ago

Nice idea but Gloucestershire Constabulary are not interested as exemplified by this prvious NMOTD. Not only was there NFA for the close pass in...

- hawkinspeter 9 hours 54 min ago

I think black boxes are great for early detection of cognitive decline and/or sight problems. Someone's driving is going to become much less smooth...

- Bigtwin 10 hours 29 min ago

It's a fashion. https://guildford-dragon.com/shalford-driver-who-smashed-shalford-war-me...

Add new comment

31 comments

@HuntBikeWheels

How do you measure the performance of your wheels in a cross wind?

I watched the live stream, I seem to recall they said they were measuring drag force (coefficient of drag, Cd) and the moment (coefficient of moment, Cm).

I thought the non zero freestream velocity in the wind tunnel would have an affect on the time averaged velocity profiles within the boundary layer, i.e. changing the boundary layer - this isnt the case. I have been assured that, becuase the refernce frame is essentially reversed, providing the control volume doesn't include field walls, all the forces are the same in the wind tunnel as real life.

As IanMunro says, the real problem comes when you are considering the ground. In real life, the velocity at the ground is zero as the air is not moving relative to the ground so there is no boundary layer. You can see in the wind tunnel that the bike is on a raised platform, I imagine suction is used to create a positive gradient, like here http://heli-air.net/img/3130/image1708.jpg

This paper concisely considers wind tunnel boundary layers (including at varying yaw angles) on ground vehicles http://c.ymcdn.com/sites/www.saimeche.org.za/resource/collection/F86B1F2...

I can only imagine the turbulent airflow caused by the boundary layer growing downstream (best case scenario, transition occurs shortly after the wheel due to turbulence) does have a fairly significant effect on the drag. I am in no way able to quanlify (let alone quantify) this as the wind tunnel I have access to is for air vehicles, not ground vehicles.

@IanMunro - thanks for the excellent explanation, and @wellsprop, both of you, very interesting.

Very interesting article (speaking as someone not overly well versed in this kind of process). Looking forward to the rest of the series. Have read very favourable reviews of Hunt wheels across the internet so they’re a brand on my radar!

Very good article, I followed the live stream closely.

Were you able to get any information on the validation of wind tunnel results, were these results tested against real world and or CFD? Also interested in the Reynolds number used, I imagine it was between 10^4 and 10^5, hence a transitional boundary layer (how was the boundary layer from the raised test platform dealt with?).

On the off chance you were able to get this info - I'm currently wind tunnel testing various disc wheel designs :p

@IanMunro

Interesting points, thank you, got me thinking - quick question, what makes the wind gradient in the wind tunnel* significantly different from that on flat ground ? The drag is measured on the wheel as a whole isn't it, including the variability due to gradient ? Obviously the wind tunnel is a more idealised environment but the actual drag measurements should still be indicative of what scale of resistance to expect and it's change with yaw angle.

* assuming you haven't got the test platform isn't raised into the flow off the floor.

The primary difference is that apparent wind component caused by the movement of a bike through air in the real world has no wind gradient, only the portion of the apparent wind caused by actual real wind will have wind gradient. So you can iether mount the wheel close to the ground in the tunnel and get a gradient in both components*, or mount it on a plate mid stream on a plate and get no gradient, but you can't mount into it any which way that will simulate the two seperate flow components correctly.

*Though I suspect the sidewall boundary layer will be markedly different to outside.

In other words, depending on setup, you can measure the equivalent of a stationary bike experience a wind hitting it at an angle or simulate bike moving though still air, but not a combination of both, or at least not correctly.

In reality the differences make very little difference compared to the human sat on top, but nevertheless companies are making claims about the relative merits of wheels based on an incorrect premise of what wind yaw angle a wheel is experiencing in the real world. So it's possible if you believe the wind-tunnel scenario to have a fat wheel X with a higher 0 yaw drag than a thin wheel Y, but with a lower 10 and 20 degree drag than the thin wheel Y, and thus a claimed lower aggreate drag. But in reality that aggregation is incorrect, because those yaw drag values are incorrect.

It's a bit like using VO2max as a metric for athletic performance. It's used not because it's a accurate indicator of performance, but because it's easy to measure. You can be pretty confident that someone with a VO2max of 30 is never going to beat a VO2max of 80, but you can say with zero confidence that someone with a VO2max of 81 is faster than someone with one of 80.

This is the problem with windtunnel yaw angles - nice and easy to measure, gives a rough indication, doesn't give a believable answer if X and Y are closely matched.

There's probably a nice PhD to be done in trying to determine if tunnel yaw values can be scaled to produce a more accurate representation of the real world. Though going down the route you also open the horrble can of worms as to what sort of turbulent air flow typical occupies the last 60 cms down to the ground on various road types.

I've had problems measuring drag in a wind tunnel due to the velocity gradient being different in the wind tunnel to real life.

It seems to be messing up the boundary layer because the velocity gradient is opposite (I.e. moving air over stationary object rather than air with no velocity being accelerated around an object). EDIT: This isn't true as I realised the refernce frame is simply reversed (this does not affect boundary layers.

The really annoying thing about this is I'm most interested in the boundary layer because I'm trying to control (delay) flow separation. I can do this in CFD but can't in the wind tunnel due to the instability at transitional Reynolds numbers.

The problem with yaw values in windtunnels, or outside for that matter is it's largely B.S

If you are moving through still air at 20mph the apparent air speed at head height is 20mph, and the apparant air speed at 50mm off the tarmac is also 20mph.

However. If you are stationary and there happens to be a 20mph wind blowing at head height, there will not be a 20mph wind blowing at 50mm off the tarmac, due to a combination of wind gradient and outside wind turbulance.

So what does this mean?

People have measured apparent wind yaw angles with onboard bike instruments placed at height somewhere between that of the top of the wheel and handlebar height. They've then made the assumption that this is then a yaw angle that stays consistent all the way down to ground. Even if you make the very optimistic assumption that you've got non turbulent wind, then at ground level you will always have a yaw angle of zero, and then as you move vertically upwards the yaw angle will become closer to that at the measument height. Of course in reality you've got hedges, grass verges and all sorts of crap next to the road that means the apparent wind a wheel really experiences bears no reality to that of simple mathemtical models.

The upshot being comparing wheels at different yaw angles in a wintunnel, is lovely in that it gives you data sets that allow you to say that wheel x performs better than wheel y at a given yaw angle, but as wheels never experence the same yaw angle across their profile when actually used on a bike outside, it doesn't appear to give any true indication of performance. It's great for adverts though

Is it BS or is it a method of evaluating the increasingly smaller variations in wheel aerodynamics? The whole point is comparing wheel x with wheel y as once you've bought the wheel it doesn't matter any more, you just ride the bike.

Everyone knows that a wind tunnel is not the real world. What we like is reliable comparisons so wind tunnel performance is probably as good as it gets.

I'm not sure that the difference in wind speed and turbulence between the ground and your headset is really all that important. In the end it's your body that causes more than 80% of the drag so the wind that hits YOU - or more specifically your aerodynamics - is what slows you down most.

The difference between wheel x and wheel y is pretty small in the scheme of things. Flo Wheels' figures for time saved with their 20-spoke 30mm wheel compares well with the baseline Mavic Open Pro with 32 round spokes but deeper rims do not have a proportional increase in time saved: http://www.flocycling.com/wheels_front_flo_30.php

Interesting - and here's another way to look at it. The tyre at the road level is stationary in a linear horizontal direction, while the top of the wheel is going something like twice as fast as the bike.

If you can't get your head around that - think of this, if the tyre isn't linearly stationary at the bottom then you are either in a skid or wheelspin scenary.

I point this out because it's another difference between the wind tunnel and real world. In the wind tunnel, at least in the case of the one Hunt used, the bottom of the wheel isn't stationary linearly along the horizontal axis in relation to the floor, although by spinng the wheels up to the same speed as the wind is being blown through, the wheels are essentially passing through the airflow in a similar way to real world scenario (the bottom of the wheel will be travelling backwords at the same speed as the wind, while the top of the wheel will have effective airflow of double the wind speed in the tunnel.

The closed I suspect you could get to the real world scenario in a wind tunnel would be to have a true rolling road (giant treadmill), although the holding of the bike would become trickier.

I've been impressed with my Hunt 4Season Aeros, solid and bearings feeling perfect half way through winter with daily riding.

But they don't weight the claimed 1579g, they're 1690g on my kitchen scales, without skewers. Does the rim tape weigh 105g per wheel? Be careful of claims about wheels

Where do you get 105g per wheel from? Even with my limited intellect I can calculate that's only 111g across both wheels!

Allowing for two layers of tape that's gotta use up a chunk of the 55.g per wheel

Even without tape, and allowing for manufacturing tolerances (of hubs, rims, spokes, bearings), extra grease, accuracy of your scales etc. that's still only about 7% difference

Touché! My bad maths. Thank you for the correction. 55g heavier per wheel it is.

55g heavier per wheel it is.

But isn't it surprising that the pair of wheels one gets to take home is always a bit heavier than the quoted value? Where are all the wheels that were lighter than the quoted figures?

These would be an ideal match for the recently announced Orro Venturi, an aero disc bike that has been "optimised for 28mm tyres". A British bike with British wheels. Nice.

(I'm actually looking to get the Venturi. Then upgrading the stock Fulcrum 4's it comes with to either the DT Swiss ERC 1400's or the Hunt 50's - I wonder how much different these new wheels will be to the existing 27mm wide version)

Nice work Luisa! Great pic too.

Impressive, always good to hear small brands stand behind their products and comment freely in forums. Same can be said for the two Doms (Fairlight & Mason) - when you're buying something over t'internet customer service like this is important. Good interaction gives me confidence that they're not just interested in box shifting and sets them apart from (for example) Ribble, Planet X, and Kinesis, all of whom have been distinctly lacking on the communication front in response to simple questions about their products.

CXR94Di2 thank you ever so much for your comment and feedback. We used 2 layers of the bronze tape up until Spring 2017 as it was pretty much an industry standard for resisting higher pressures, however as you correctlly point out it is not as good at sealing as other types of tape used on lower pressure MTB wheels. We now use a proprietory 2 layer 2 tape system, with a highly felxible well sealing cream tape under the bronze tape. Please note that the bronze tape has a very high tensile strength so does not creep over time with high pressures, that is why we still use it for the top layer. as an existing HUNT wheels customer we would be delighted to send you a full set of these tapes free of charge please just email us on thechase [at] huntbikewheels.com and we will send it out straight away. The single layer bronze tape was only used for our wind tunnel testing in the images in this article as we were obviously not riding these wheels and fitting tyres to the rapid protoypes was tighter than real rims as the inner surface finish was not smoothed like the outer surface.

paulrattew, usedtobefaster you have posted very well made points. We are definately considering how the yaw angles alter at different riding speeds, we are also preparing some research calculations on rolling resistance vs aero effect at different speed ranges.

The 45-48kmhr traditionally used for wind tunnel testing is, as you can probably work out, the kind of speed a TT pro would ride at, as you correctly state slower speeds around 22-25mph on the flat are much more realistic for a drop bar road bike and for real riders more like us, obviously these speeds alter over distance and terrain. You're abolsutely right that the yaw angle would significantly widen at these lower speeds and Pete and Luisa here are currently doing a lot of calculations (they used the word integration which scares me from my a-level physics!) to work out the time likely to be spent at each wind yaw angle. They are using the wind data other maufacturers have used in their wind averaged drag models to give us the best picture of which yaw angles drag is most important for realistic riding speeds. Also, we already have plans and capabilities to record wind yaw angles on bike, but of course we want to use other companies data and WAD models to show we are not just creating wind data that suits our product. We'll release a lot more data and information soon.

variflex, thank you ever so much for your feedback and I feel we owe you a better level of service here. We are all riders and never want a rider to feel the way you do about HUNT wheels, of course it is in our best interests and the riders we serve that you have a set of HUNT wheels you are happy with. We have a policy of never leaving riders unhappy if at all possible, so we have clearly let you down in this case. We will be in contact shortly to find the best path possible for you. I would like to assure you that the current model of Aero Light Disc wheels, whilst being designed as a fast lightweight performance wheelset with superlight hubs, has larger bearings and more extensive bearing shielding. I suspect the hubs you are using are an earlier model and no longer used on any of our wheels, they were specced as the offered the ultimate in fair weather performance for this fast/light wheelset. For our 4Season range we put a special emphasis on bearing longevity, and we have applied similar thoughts to the full range now and even to the extreme of speccing our own waterproof grease (which costs $1500 for 10kg) and have special operating procedures for grease application. We go to these lengths as British all weather riders like yourself we want bearings to last as long as possible. As I say, we will be in contact shortly and I'm very hopeful we can find a resolution that will work well for you.

Thank you all again for your comments and replies and I did just say to Mat at road.cc "these are very well informed comments...I have to say the readers have answered some of the comments so well and have covered quite a few of the points we would make in replies, pretty impressive. There is definitely another level of reader on road.cc compared to any other site I've been on."

Your help and advice really does go into helping us make better wheels for all of us riders so thank you again ever so much,

Tom Marchment HUNT | TheRiderFirm

There is no necessity to send me some rim tape, but thankyou for the gesture.

Interesting reading. So the drag at certain yaw angle is different depending on the speed and from what I've observed the marketing of aero bikes wheels etc mostly refers to riding at 40km/h e.g. a 10sec saving at 40km/h, so we can assume that products are designed to be optimal at and above this speed. Sounds like there's a space in the market for products optimised for lower speeds where I suspect a lot of riders spend a majority of time riding at, say 30km/h, and so could benefit from reduced drag, particularly looking at the benefit in longer events and endurance riding - after all how many riders can ride a 100 mile sportive at 25mph that's got to be a small market surely?

Part of the reason that testing tends to use 40 or 50pkh is because the higher speeds make it easier to measure differences reliably. Lower speeds to not really change the way in which the aerodynamics work, the impact though would be smaller. Generally spaeking if the results show that one wheel is more aero than another at 40kph across the range of yaw angles tested, then that same wheel will be more aerodynamic at 30kph (the impact of this though will be proportionally smaller).

One of the big differences at lower speeds is that relative yaw angles are higher, which is why it's important to understand performance across a wide range of yaw angles.

Love my Aerolight wheels apart from the bearings.. suposedly upgraded but have lasted less than 600kms on the rear wheel. Main hub and free hub knackered. Hunt wherent too interested and suggested buying more of their bearings. No thanks, have upgraded to Enduro for the same cost.

None of my numerous other wheelsets have ever needed bearing changes before several years use and some still going strong after 4 years.

Good luck with the wind tunnel work and development... but pls get the bearings right first!

Hi Variflex,

I am sorry to hear you're not satisfied with your bearings. If you could email us at thechase [at] huntbikewheels.com and we will do everything we can to make you happy!

I look forward to hearing from you,

Jack @ HUNT Bike Wheels.

Dear Hunt Wheels, please stop using that transparent rim tape, it is terrible. I kept losing pressure when I bought wheels with it installed. Please use Stans tape or something equally good. Since renewing with Stans tape, the wheels have kept pressure.

I must say I do like your wheels

God really? I avoid Stans, I find it too thick and stiff to work into the 'tyre well'... I find the 3M made high tensile tape (as above) superb. Been using just one layer of it my front road wheel now for well over 12months, with no issues. I suspect that your particular bad experience was down to it being fitted badly, either A. it wasn't worked into the 'well' enough or B. the rim wasn't cleaned enough before fitting.

@Hunt - curious why you've changed to two types of tape per wheel?

I have a set of Stan's Avions so would love to see how these compare with the competition (and of course with Hunt's existing and prototype models). I think that I'm probably quite similar to most people in that the aerodynamic qualities of a wheel are part of the attraction, but not all of it.

Price, comfort, build quality and liveability are all at least as important.

If I'm running tubeless tyres then I don't want wheels with internal nipples, even if they are more aerodynamic. Making any adjustments to the wheels to keep them in true is a complete faff if the nipples are internal and you're running tubeless - so internal nipples fail the 'liveability' test for me.

A wheel can be super aero but can feel really harsh when taken away from perfectly smooth tarmac, even with plump 28mm tyres. One of the things I love about the Avion's is the way they feel across the full range of British road surfaces. Part of this seems to be a hangover of designing rims for rim brakes, where the resins need a much higher tg point due to the more extreme temperatures caused by rim braking. Disc brake wheels need fundementally different design as the forces and conditions they are exposed to are different.

The Hunt wheels will have external nipples for those reasons. Ernst – who runs the wind tunnel – reckons the aero advantage of internal nipples is minimal.

It's the right way around in all the pictures. Think you're mistaking the air intake for the fan.

You're totally right, shows I should pay more attention early in the morning, one large blue shape on the wall isn't the same as another similar looking large blue shape on the wall!

Great article, really interesting to see their process. I think the extra transparency that they're allwing with their design (whilst still keeping certain things a bit of a secret) is refreshing. I get why they don't, but if manufacturers were more willing to show their method for calculation, or sent their wheels to someone independant for testing it would be interesting (although I imagine a few brands might be a bit worried about that).

Also good to see the bike the right way round in the tunnel (except one of the first pictures) so many promo shots show wind tunnel testing with the fans in front rather than drawing air from behind.

Looking forward to the next installment.

Pages