- News

- Reviews

- Bikes

- Accessories

- Accessories - misc

- Computer mounts

- Bags

- Bar ends

- Bike bags & cases

- Bottle cages

- Bottles

- Cameras

- Car racks

- Child seats

- Computers

- Glasses

- GPS units

- Helmets

- Lights - front

- Lights - rear

- Lights - sets

- Locks

- Mirrors

- Mudguards

- Racks

- Pumps & CO2 inflators

- Puncture kits

- Reflectives

- Smart watches

- Stands and racks

- Trailers

- Clothing

- Components

- Bar tape & grips

- Bottom brackets

- Brake & gear cables

- Brake & STI levers

- Brake pads & spares

- Brakes

- Cassettes & freewheels

- Chains

- Chainsets & chainrings

- Derailleurs - front

- Derailleurs - rear

- Forks

- Gear levers & shifters

- Groupsets

- Handlebars & extensions

- Headsets

- Hubs

- Inner tubes

- Pedals

- Quick releases & skewers

- Saddles

- Seatposts

- Stems

- Wheels

- Tyres

- Health, fitness and nutrition

- Tools and workshop

- Miscellaneous

- Tubeless valves

- Buyers Guides

- Features

- Forum

- Recommends

- Podcast

TECH NEWS

Is Specialized set to release new bump-absorbing (don't call it suspension) fork?

Patents unearthed by Bikerumour hint at a new fork in development by Specialized that utilises technology from their Roubaix bikes and CG-R seatpost to provide 2-4mm of vertical suspension. It will be a disc-only fork and use a bolt-thru axle. The latest patent was filed in September 2014, but there’s no indication the fork will see the light of day for a while yet.

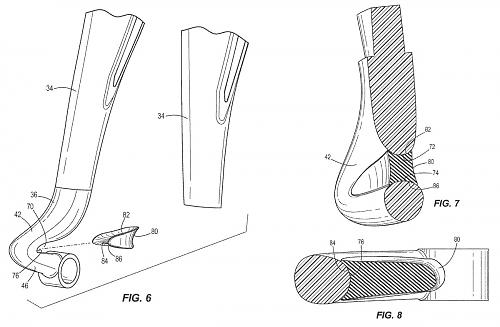

Specialized have designed a fork with specifically shaped lower legs with two arms and an open space, to be filled by a Zertz elastomer to control the range of movement. This design provides up to 4mm of vertical movement, which while not a huge amount, would certainly make a difference on rough roads or cobbles. In essence it’s an extension of Specialized’s Zertz vibration damping features found on the Roubaix.

It’s not a suspension fork of course, there’s no spring, though we’ve had suspension forks on road bikes in the past. RockShox trialled the Paris-Roubaix SL fork some 20 years ago, with 30mm of damped suspension travel. It went on to win three editions of Paris-Roubaix, before promptly vanishing into the history books.

Comfort enhancing features though have become a key feature on the latest generation of endurance and sportive bikes. There’s the Roubaix from Specialized of course, plus the likes of the Cannondale Synapse, Trek Domane, Bianchi Infinito and Lapierre Pulsium. Each employ different designs that are ultimately intended to provide a smoother ride, whether it’s for tackling a cobbled Classic or your local roads on a Sunday morning spin.

The patent is very detailed with regards to the specification of the lower fork legs, setting out the desirable angles.

“The fork tip includes a first arm extending at an angle of 20-100 degrees (preferably 40-85 degrees, and more preferably 66 degrees) relative to the steering axis, a second arm extending at an angle of 50-140 degrees (preferably 70-120 degrees, and more preferably 114 degrees) relative to the steering axis, and an axle support coupled between the second arm and the front wheel. In one embodiment, the first arm and second arm define a gap, and the fork tip further includes a resilient member positioned in the gap.”

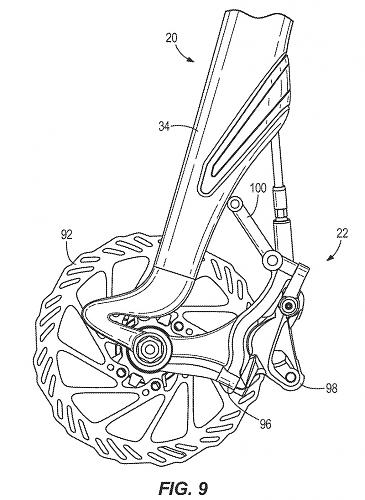

The pictures show a disc brake and thru-axle. Obviously with the small range of vertical movement of the axle, a regular rim brake is out of the question, so it’ll be a disc-only fork. Specialized already offer the Roubaix and Tarmac with disc brakes so no problems there. As the disc brake caliper lower mount is attached to the axle, it’ll move in relation to the upper fork. To counteract this, Specialized have used a small linking arm that allows the caliper to move upwards and remain in the ideal position over the disc rotor at all times.

Interestingly the patent clearly shows a thru-axle (though its diameter isn’t clear, it could be 12 or 15mm) which will perhaps be a necessity to provide the required stiffness for the fork. Specialized have currently stuck with regular quick release axles on their disc-equipped road bikes, so could this be the start of the much anticipated shift to thru-axles on disc road bikes?

Source: Bikerumour.

David worked on the road.cc tech team from 2012-2020. Previously he was editor of Bikemagic.com and before that staff writer at RCUK. He's a seasoned cyclist of all disciplines, from road to mountain biking, touring to cyclo-cross, he only wishes he had time to ride them all. He's mildly competitive, though he'll never admit it, and is a frequent road racer but is too lazy to do really well. He currently resides in the Cotswolds, and you can now find him over on his own YouTube channel David Arthur - Just Ride Bikes.

Latest Comments

- matthewn5 57 min 10 sec ago

A club member had just had his 12 speed Shimano Hollowtech cranks fail... same way that the 11 speed cranks failed.

- MattieKempy 1 hour 11 min ago

Currently watching the Cyclocross Worlds on www.Sporza.be using my vpn, which I have anyway, free through my bank account. OK, so it's in Dutch,...

- chrisonabike 1 hour 42 min ago

EDIT - Cycle Happy got there first!...

- Shackbu 1 hour 55 min ago

I have Eurosport as part of my Virgin TV package. They contacted me yesterday to say that becasue Eurosport was closing down they would give me TNT...

- rickiecheese 2 hours 42 min ago

An update regarding this path....

- tony.westclassics@live.co.uk 3 hours 43 min ago

Theres no boubt about it, this bloke is the kiss of death

- don simon fbpe 3 hours 57 min ago

As you agree with me, I don't understand your point.

- Rendel Harris 4 hours 1 min ago

Absolutely without a doubt, a small example recently: I was cycling down The Mall in London from Buckingham Palace towards Admiralty Arch and...

- Rendel Harris 4 hours 35 min ago

The jacket looks funky but as far as I can see from the photographs isn't anything like as bright when hit by light as ProViz or similar more...

- cardch 5 hours 41 min ago

Just ordered mine. Went to visit them and it's a great setup, and so nice (I hope) to get something with a bit of soul, rather than another...

Add new comment

20 comments

I thought polymer based suspension systems had been pretty much discredited. Polymers are affected by temperature too much to provide a consistent level of performance.

It's not polymer based. It uses flex in the carbon fibre, the polymer is simply there because people don't like large holes in the middle of their frame. Specialized actually admitted a few years ago with the Roubaix that the polymer was a visual thing to dispel any worries.

Much like putting sipes or tread on road tyres, it makes bugger all difference to grip or water dispelling ability but people don't like to see smooth tyres, they think they'll slip.

Tread on road tyres can make a small difference (according to at least one tyre manufacturer). It's been discussed on here a few times IIRC.

"RockShox trialled the Paris-Roubaix SL fork some 20 years ago, with 30mm of damped suspension travel. It went on to win three editions of Paris-Roubaix, before promptly vanishing into the history books."

Still a few around. A Yorkshire bloke rode one in last year's Paris-Roubaix sportive, using quite high pressures. He thought it was fine. Andre Tchmil and Gilbert Duclos-Lassalle used them.

Won't be an issue. Disc brake rub is caused by the wheel flexing in the dropouts. Here you have a bolt-thru axle and the wheel, disc caliper and lower legs are all connected, it's effectively one unit.

The only part moving is the middle of the legs, the lower bit of wheel, disc rotor, disc caliper and bottom half of the fork legs all moves as one therefore no rub.

And even if it does rub, it's so slight that it makes no difference other than a slightly irritating noise. And you can get that same rub from sprinting out of the saddle with rim brakes.

The difference between Specialized/Trek and Giant/Merida? Specialized and Trek seem to go for clearly visible easily marketable gimmicks, while Merida and Giant tend to go for engineering the frame material alone and/or sorted well engineered stuff that works with no bells or whistles. Both approaches seem to just but one means the bikes look cleaner but the stuff that does stuff is hidden away and therefore less easy for the marketing guys to grasp and the public to spot.

And before anyone comes back with 'Maestro' or other such stuff that Giant or Merida have produced, you tend to find that these were pure engineering solutions first that the marketing guys then had to put a name to, where-as with the Specialized and trek stuff it seems to me that the designers were deliberately looking for something that would stand out (i.e. easily marketed) as well as just trying solve an issue.

The Trek solution (IsoSpeed decoupler) is not a gimmick - it's a very simple bit of engineering that works very well.

umm, really? Yes it works, but isn't it a bit of a case of 'you know what, instead of spending time working out how to improve the dampening that the tubeset provides but retaining lateral stiffness, we'll just disconnect the seat tube at the top'.

Simple, yes. lazy, yes. Oh, and easily marketable because it very obvious and easy to demonstrate/understand.

So Merida and Giant gimmicks are engineering driven but Spesh and Trek's gimmicks are marketing driven? You know this how? They are all the same. One part engineering to four parts bollocks.

Also, Merida have never produced (road) bike that is anything but ugly.

So Merida and Giant gimmicks are engineering driven but Spesh and Trek's gimmicks are marketing driven? You know this how? They are all the same. One part engineering to four parts bollocks.

Also, Merida have never produced (road) bike that is anything but ugly.[/quote]

I don't know it, and I'm sure there are exceptions both ways, but ever wondered why the trek and spesh stuff is much more obvious when looking at a bike? Simple, it stands out, is easily spotted/demonstrated, and thus more easily marketed.

Re Merida and ugly bikes, sort of agree, but if you see them in the flesh you'll realise that it's down to them having a rubbish graphics dept as the frames underneath look pretty good (example: check out the ride carbon disc 3000 - really subtle graphics that helps make the frame really stand out, yet similarly shaped scultura frames often look average at best due to decals).

Good for people who still don't understand what pneumatic tyres are for and believe that 25mm (used to be 23mm) at 100PSI is the only way to go fast...

Indeed...even 28mm's for me now, sweet spot seems about 65psi front, 90-95psi rear. Bike and I together come in about 87kg. Rough Cornish roads however!

All very high tech.

Can also be solved by a traditional curved steel fork with disc tabs...!

FlexStem! Make a come back!

Seriously though, since the wheel will be 'suspended' it should give better handling over cobbles or over very rough road surfaces. Good idea, but preventing the flex induced disc brake rub will be the deciding challenge imo.

Fig 1 only appears to have a front brake

If the purpose is road buzz isolation, wouldn't it make more sense to solve this in the bit of the bike above the headset?

You mean like Cannondales old HeadShocz system (probably spelt that wrongly).

The problem is there's a certain amount of stiction involved wrt things moving - I've got a rather similar, but more basic version of the front end of my recumbent. Works well enough on bigger stuff, but not so good on smaller/buzzy stuff

Plus the forks just add to the unsuspended mass.

It is a suspension fork. Just because the spring isn't a metal coil doesn't mean that there isn't a spring.

Interesting to see that they are looking to the future and basing it around disc forks as opposed to traditional caliper brakes.

Don't you reckon it could see light of day on their gravel/cross bikes such as the Diverge ?

The Tricross used to have Zertz inserts in the forks. (Hard to tell if it made a difference though without putting a 'normal' set of forks on and comparing)