- News

- Reviews

- Bikes

- Components

- Bar tape & grips

- Bottom brackets

- Brake & gear cables

- Brake & STI levers

- Brake pads & spares

- Brakes

- Cassettes & freewheels

- Chains

- Chainsets & chainrings

- Derailleurs - front

- Derailleurs - rear

- Forks

- Gear levers & shifters

- Groupsets

- Handlebars & extensions

- Headsets

- Hubs

- Inner tubes

- Pedals

- Quick releases & skewers

- Saddles

- Seatposts

- Stems

- Wheels

- Tyres

- Tubeless valves

- Accessories

- Accessories - misc

- Computer mounts

- Bags

- Bar ends

- Bike bags & cases

- Bottle cages

- Bottles

- Cameras

- Car racks

- Child seats

- Computers

- Glasses

- GPS units

- Helmets

- Lights - front

- Lights - rear

- Lights - sets

- Locks

- Mirrors

- Mudguards

- Racks

- Pumps & CO2 inflators

- Puncture kits

- Reflectives

- Smart watches

- Stands and racks

- Trailers

- Clothing

- Health, fitness and nutrition

- Tools and workshop

- Miscellaneous

- Buyers Guides

- Features

- Forum

- Recommends

- Podcast

TECH NEWS

Wiggins Pinarello Bolide HR white paper - 2

Wiggins Pinarello Bolide HR white paper - 2Bradley Wiggins’ Hour Record: the Pinarello Bolide he rode

Pinarello has published a white paper detailing aspects of the Bolide HR’s design that Bradley Wiggins' rode for his UCI Hour Record this evening.

According to Pinarello, the main characteristics of the bike are:

• Similar tubing sections to the existing Bolide

• Same geometry as the existing Bolide

• Aero-optimised fork and seatstays, which are very close to the wheel’s profile

• Aero-optimized front dropout

• 3D Printed titanium handlebar

• UCI approved

We ran a story earlier today showing some of the aerodynamic developments that Pinarello and Jaguar, co-engineering the project, had made to the Bolide and this new white paper gives us more details.

Pinarello says that the main considerations in the design process were aerodynamics – the most important consideration because of the high speed involved – and the stiffness, to transfer the rider’s energy to the rear wheel.

The work on aerodynamics was done using CFD (computational fluid dynamics) simulations, with the road version of the Bolide as the start point.

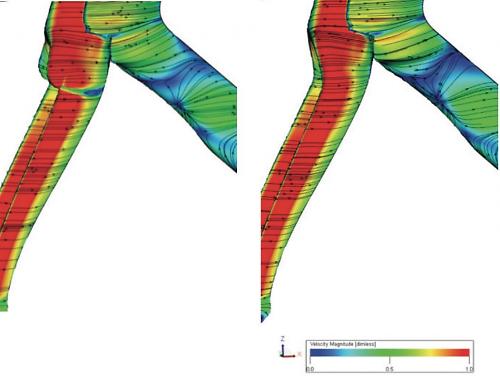

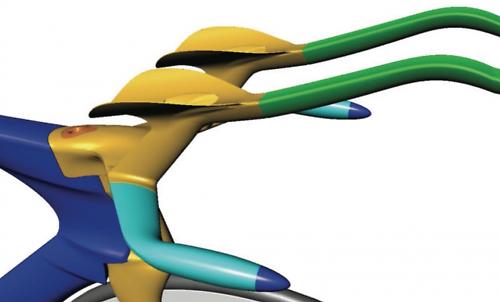

The road Bolide (above left) has a fork with a nose that’s shaped to house the front brake but you don’t have brakes on a track bike so the designers had scope to alter that area. They say that smoothing the fork surfaces (above right) has led to a significant decrease in drag.

The designers could have widened the fork stance to increase the space for airflow and reduce drag in that way, but they decided to take a different approach, minimising the gap between the wheel and the fork legs to prevent air passing through.

The front dropout has been modified to reduce the detachment of the airflow, reduce turbulence behind the dropout and so to decrease drag.

Further modifications were made to other parts of the frame and the components, including the rear wheel and the handlebar.

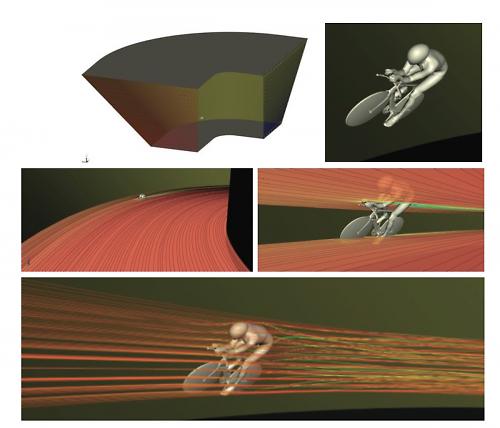

“A further analysis was performed to check the aero performance considering the track characteristics (most velodromes today are 250 m long and the maximum banking is about 42°),” says Pinarello.

“The rider will spend almost half of the time on the curves, so the airflow will have also a lateral component, which is calculable. Again, using CFD, this condition was analysed and… the effect on the performance of the bike [measured].”

When it comes to frame rigidity, Pinarello says, “Increased stiffness… allows better power transfer to the rear wheel, without wasting energy by flexing the frame and therefore pulling the wheels out of alignment in every pedal stroke."

See, there's a reason we go on about frame stiffness in most of our bike reviews!

“Composite materials allow the production of very stiff frames, with a low weight; at the same time, a proper design and production technique could further increase the performance. Traditional frames, for cost and time reasons, are usually produced in two or more parts, then bonded together, because this method allows quicker and cheaper production. At the same time, the bonding areas require more material (to allow the overlapping of the parts), which means more weight and creates zone of possible stress concentration.

“To solve all these problems the frame is made as a one piece composite with no bonded parts after curing; this resulted in a light and stiff frame.”

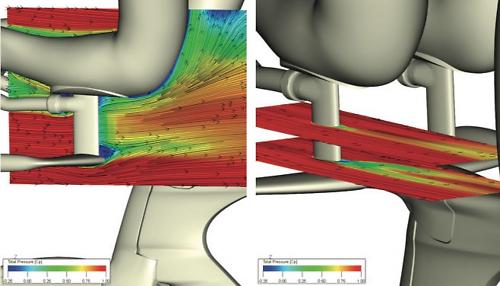

The designers paid particular attention to the design of the handlebar because it has a major influence on the aero performance of the whole bike thanks to its position at the front.

“Behind the spacers for the arm rests, a low pressure zone is generated, because of the transition between the parts,” says Pinarello. “A proper design of this zone helps to reduce this, and consequently the drag.

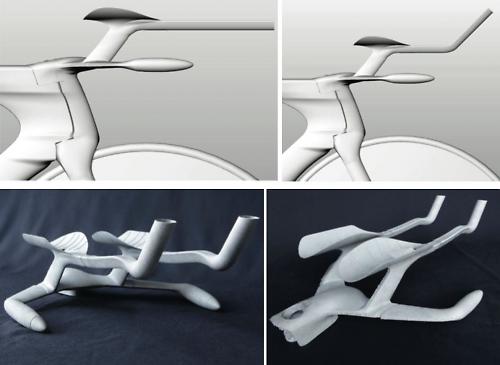

“Standard technologies, such as CNC or carbon molding, would be excessively long and expensive to produce this particular shape, so we used an Additive Manufacturing method (also known as 3D Prining) to manufacture a titanium handlebar.

"In the additive manufacturing technique a high energy source locally melts the powdered material (typically metal), as defined by a 3D model, binding the material together to create a solid structure.

“The capabilities of this technology allowed [us] to produce a small batch of handlebars, everyone different from the other… This method will now be used to provide a similar service to Pinarello customers via the MOST parts brand.”

The white paper has now been published on Pinarello's website

Mat has been in cycling media since 1996, on titles including BikeRadar, Total Bike, Total Mountain Bike, What Mountain Bike and Mountain Biking UK, and he has been editor of 220 Triathlon and Cycling Plus. Mat has been road.cc technical editor for over a decade, testing bikes, fettling the latest kit, and trying out the most up-to-the-minute clothing. He has won his category in Ironman UK 70.3 and finished on the podium in both marathons he has run. Mat is a Cambridge graduate who did a post-grad in magazine journalism, and he is a winner of the Cycling Media Award for Specialist Online Writer. Now over 50, he's riding road and gravel bikes most days for fun and fitness rather than training for competitions.

Latest Comments

- chrisonabike 2 sec ago

What is "progress" though?...

- mctrials23 54 min 31 sec ago

Theres only 2 things I can't stand in this world. People who are intolerant of other peoples cultures...and the dutch.

- cyclisto 1 hour 24 min ago

I know the Limes made a mess, but my inner self sees a bicycle commuter porn image.

- Secret_squirrel 2 hours 4 min ago

Thats if you believe that a slightly bigger bearing surface translates in any meaningful way to "pedaling stiffness" which to my mind is the...

- chrisonabike 2 hours 10 min ago

Everyone carrying more / brighter searchlights will fix things? Perhaps it helps sometimes, but I think this leads to other issues. We're already...

- SecretSam 2 hours 11 min ago

Lake's naming and sizing: never knowingly comprehensible. Good shoes, baffling range.

- hawkinspeter 2 hours 15 min ago

Yeah, I doubt if Arron Banks would be happy visiting "little Somalia" (as he referred to Bristol) and certainly I don't think Bristol's residents...

- ChasP 2 hours 52 min ago

It could be used as a reliable comparison without any calculations.

Add new comment

13 comments

I don't think Merckx was any worse a doper than other top guy of his era, and remember, most of it wasn't banned then.

And remember, Eddy was a heavy smoker, so it probably balanced things out.

Amazing to think that in 1972 Eddy Merckx almost managed 50km on a standard road bike. With all the modern advantages todays racers have, the record has not moved forward very much.

Shows just how good Merckx was! your only as good as your engine and since 1972 athletes havn't evolved that much.

Merckx was at altitude, I wonder if that counters part of the technological gains between his ride and Wiggins's. Also, Merckx was a massive doper, so that probably adds a couple of k to his ride. Swings and roundabouts.

I recall something by Dr Hutch that said there is a balance to be had with altitude as the lower air pressure whilst being good for aerodynamics comes at the cost of aerobic efficiency/available oxygen for the cyclist.

The Wiggins team were apparently a little concerned about the high pressure sitting over the lower half of the UK at the w/e but I quite enjoyed the weather it brought!

Indeed. Hence the saying "live high, train low". To match the same intensity at altitude, you have to up the effort.

Was he really a massive doper? Why does everyone make out his the greatest cyclist then (I'm not saying he isn't), is it that most people don't know?

Could just have asked Graeme Obree, less pictures Nd press releases, more action.

Could just have asked Graeme Obree, less pictures Nd press releases, more action.

http://www.pinarello.com/en/bike-2016/road/dogma-f8/at_download/images_pdf

Could we have a link to the white paper please? I can't find it

He's got no excuse if he doesn't beat Dowsett's record

There were a few recent stories showing quite silly 3D printed bike parts. This is what real 3D printing looks like, and making one off parts to a specific fit is something it's brilliant for.

And it's done with freaking laser beams, so that makes it cool.