- News

- Reviews

- Bikes

- Accessories

- Accessories - misc

- Computer mounts

- Bags

- Bar ends

- Bike bags & cases

- Bottle cages

- Bottles

- Cameras

- Car racks

- Child seats

- Computers

- Glasses

- GPS units

- Helmets

- Lights - front

- Lights - rear

- Lights - sets

- Locks

- Mirrors

- Mudguards

- Racks

- Pumps & CO2 inflators

- Puncture kits

- Reflectives

- Smart watches

- Stands and racks

- Trailers

- Clothing

- Components

- Bar tape & grips

- Bottom brackets

- Brake & gear cables

- Brake & STI levers

- Brake pads & spares

- Brakes

- Cassettes & freewheels

- Chains

- Chainsets & chainrings

- Derailleurs - front

- Derailleurs - rear

- Forks

- Gear levers & shifters

- Groupsets

- Handlebars & extensions

- Headsets

- Hubs

- Inner tubes

- Pedals

- Quick releases & skewers

- Saddles

- Seatposts

- Stems

- Wheels

- Tyres

- Health, fitness and nutrition

- Tools and workshop

- Miscellaneous

- Cross country mountain bikes

- Tubeless valves

- Buyers Guides

- Features

- Forum

- Recommends

- Podcast

TECH NEWS

2022 LeMond 8 - 7.jpeg

2022 LeMond 8 - 7.jpegLeMond is promising "transformative change" to carbon construction with all new 8 road bike

LeMond has unveiled its new 8 performance road bike which it says represents “a new bar for top-tier frame design and manufacture” thanks to the composites technology and expertise used. The US-made frame and fork are entirely carbon-fibre down to the threads for the bottle cages and brakes.

Greg LeMond has been promising performance road bikes using new carbon processes for years and has developed a new carbon fibre production facility in Tennessee, USA. Although the LeMond 8 hasn’t been officially launched yet, details are available online.

LeMond confirms new bike line is on the way

“The LeMond 8 MatrixCore blends composite sandwich construction methods from the aerospace industry using a new ultra-lightweight dual expanding foam made by Xenecore,” says LeMond.

“The Xenecore dual expanding foam stays inside the frame and fork for superior carbon fibre ply consolidation. This foam replaces the need for plastic and pneumatic bladders, and has the added comfort benefit of damping vibration that may otherwise drain a rider’s energy.”

LeMond says that it “optimises the Xenecore foam by locally incorporating internal carbon fibre reinforced truss structures to increase strength, durability, and stiffness where desired”.

It claims that this allows it to produce frames that are among the strongest and safest in the world.

LeMond also says that its composites expertise allows it to incorporate innovative engineering that improves the final product.

“With LeMond’s ability to create internal structures along load paths that make sense, less overall fibre may be used, resulting in a lighter, stronger frame than is possible with traditional techniques,” it says.

The LeMond 8 frame and fork are made entirely from carbon fibre right down to details which are usually made from other materials.

“Each threaded water bottle and brake boss is carbon fibre – lighter, stronger, while also preventing any possible galvanic oxidation of the aluminium parts, making them prone to failure,” it says.

LeMond has chosen to use a T47 threaded bottom bracket rather than a press-fit design, fitted into a BB shell that uses what it calls a carbon-fibre lattice construction technique.

“This ultra-strong web-like cylinder is co-cured into the frame for a unibody construction with immense lateral stiffness, [providing] all the benefits of a threaded BB without the weight penalty,” says LeMond.

The LeMond 8 can be fitted with the brand’s integrated carbon fibre handlebar/stem or with a standard LeMond carbon fibre handlebar.

“Multiple reach, width, and grip size dimensions are available, with a subtle 5-degree flare, fully integrated cables, spacers up to 30mm, and a computer mount that fits flush to the underside of the bar,” says LeMond.

The inside of the fork steerer features full-length structural ribs with internal threads that the headset top cap can be tightened against so there’s no need for an expander wedge. It looks like Xenecore foam is used in this area. The steerer can still be cut down in the normal way to adjust handlebar height.

Speaking of fit, the LeMond 8 uses a dedicated seatpost clamp system that locks into a channel at the rear of the post. LeMond says that this design spreads the clamping load over 66mm of post to minimise the possibility of damage.

The channel will also be able to accept LED lights, saddlebags, and other accessories when released.

The LeMond 8 has clearance for tyres up to 32mm wide with three Vittoria Corsa models available at purchase in 25mm, 28mm, and 30mm widths. It comes with a replaceable direct-mount derailleur hanger that’s made from – you’ll never guess – carbon fibre.

In terms of drag, LeMond says, “The LeMond 8 incorporates aerodynamic forms such as a Kamm tail down tube with rounded edges and a head tube narrower than most with internal cable routing.

“The LeMond 8 system has been optimised for slicing cleanly through the wind, with fully integrated cables and a slim front profile. Rather than having to choose between lightweight and aero, Greg’s goal has always been to optimise one bike for both climbing and riding at high speed without compromise.”

LeMond doesn’t, though, at this stage offer any data comparing the 8’s aero efficiency with that of any other bikes.

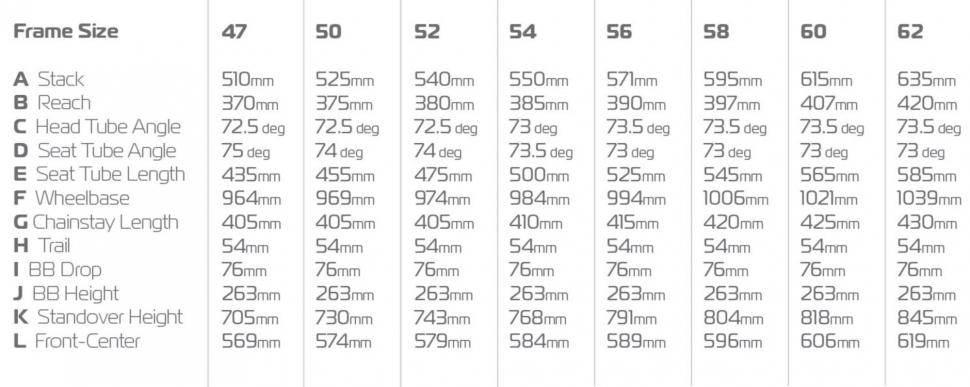

The LeMond 8 is available in eight different sizes from 47cm to 62cm.

LeMond hasn’t supplied top tube or head tube lengths but the 56cm model, for example, comes with a stack of 571mm and a reach of 390mm. That gives a stack/reach of 1.46. That doesn’t suggest a ride position that’s especially aggressive or particularly relaxed, sitting about midway between Trek’s H1.5 and H2 fits, if you’re familiar with those.

The complete bike build is:

Frameset LeMond 8 carbon fibre MatrixCore

Cockpit option 1 LeMond aero monocoque bar/stem

Cockpit option 2 LeMond carbon fibre stem and handlebar

Front derailleur Shimano Dura-Ace FD-R9250

Rear derailleur Shimano Dura-Ace RD-R9250

Chainset Shimano Dura-Ace FC-R9200 52/36T

Cassette Shimano Dura-Ace CS-R9200-12 11-30T

Chain Shimano XTR CN-M9100

Bottom bracket T47 threaded

Brake levers Shimano Dura-Ace ST-R9270 hydraulic

Brake callipers Shimano Dura-Ace BR-R9270 hydraulic

Rotors Shimano RT-MT900

Saddle Fizik Antares Versus Evo 00 Adaptive

Rims LeMond LC 47 Tubeless

Front hub Tune KillHill CL 100x12mm

Rear hub Tune ClimbHill CL 142x12mm

Spokes Sapim bladed

Tyre option 1 Vittoria Corsa 700c x 25mm

Tyre option 2 Vittoria Corsa Control 700c x 28mm

Tyre option 3 Vittoria Corsa Control 700c x 30mm

This build is priced £11,400.

A frame/fork, handlebar/stem, seatpost and wheelset is £7,800. The LeMond 8 frameset is for electronic shifting only.

These prices include VAT. No weights have been published for the complete bikes or the frame.

LeMond 8 deliveries are expected to begin in July 2022, just after Shimano Dura-Ace R9200 Shimano Dura-Ace Di2 groupsets are scheduled to arrive.

Along with the bike, you get membership of Team LeMond.

“As a Team LeMond member, you will have exclusive access to annual private rides with Greg and his team, in Europe and the USA, free entry into cycling events, and early access to new products that LeMond is developing, even helping us to evaluate and test new products,” says LeMond.

“In addition, Team LeMond members will receive annual cycling kits, including jerseys, shorts, and socks, and quarterly ‘Town Hall’ talks with Greg via Zoom.”

Team LeMond members are also entitled to 50% discount on all LeMond carbon fibre manufactured framesets, wheelsets, and new carbon fibre components that it plans to develop over the next 3-4 years.

This includes a LeMond 8 Aero Gravel Frame which we’ve not heard about previously.

The LeMond 8’s name, if you haven’t guessed, is a reference to Greg LeMond’s winning margin in seconds in the 1989 Tour de France. LeMond opted to use aerobars – innovative technology at the time – on the final stage time trial to wrestle victory from Laurent Fignon.

For more info go to lemond.com

Mat has been in cycling media since 1996, on titles including BikeRadar, Total Bike, Total Mountain Bike, What Mountain Bike and Mountain Biking UK, and he has been editor of 220 Triathlon and Cycling Plus. Mat has been road.cc technical editor for over a decade, testing bikes, fettling the latest kit, and trying out the most up-to-the-minute clothing. He has won his category in Ironman UK 70.3 and finished on the podium in both marathons he has run. Mat is a Cambridge graduate who did a post-grad in magazine journalism, and he is a winner of the Cycling Media Award for Specialist Online Writer. Now over 50, he's riding road and gravel bikes most days for fun and fitness rather than training for competitions.

Latest Comments

- SecretSam 6 min 52 sec ago

Said the spokesperson for Big Hookless

- chrisonabike 15 min 22 sec ago

I think the complaint - if it is in good faith (which is a question...) - may stem from:...

- the little onion 15 min 31 sec ago

Here is a cracker of a report, with coroner's comments, on the BBC...

- mitsky 24 min ago

Is that same sergeant as keen to prosecute drivers who stray into cycle lanes...? I'm not betting on it.

- quiff 37 min 16 sec ago

There's a lot going on in this report....

- Jamminatrix 36 min 13 sec ago

It's all well and good, but what was in the jiffy bag, Wiggo.

- Secret_squirrel 45 min 24 sec ago

Hey FrankH (or are you Nigel in disguise). Take your shit-stirring and fuck off elsewhere....

- mdavidford 1 hour 13 min ago

Well - different reviewers, so different experiences - what works for one person can be annoying and fiddly for the next.

- KDee 1 hour 27 min ago

That's what the article seems to say. Surprised I didn't get an email from Komoot explaining the new fees, but that I'm excluded with that world...

- dave atkinson 2 hours 32 min ago

we were SO lucky with the weather on this one. i've done the butt buster a month later in temperatures that never got above freezing

Add new comment

16 comments

Looks like every other carbon bike on the market atm, nice looking frames but those graphics?

I think Greg Lemond used aero bars to WREST victory in the Tour de France from Laurent Fignon. I don't think WRESTLING was involved.

I find this carbon fiber bike craze laughable! I find it amazing that most cyclists are environmentally forward in their thinking, yet think nothing about buying a carbon fiber bike that uses 14 TIMES the energy to make one bike vs making one steel bike! And the creation process spews out a significant more amount of greenhouse gases then steel bikes did. Plus, recycling carbon fiber takes more energy than steel to recycle. Carbon fiber is neither biodegradable nor photodegradable so it will remain in a landfill for eternity, while at least steel if left in a landfill will eventually crumble to pieces as it rusts into eventually nothingness. Carbon fiber bikes of all the materials like steel, aluminium, and titanium, is by far worse for the environment then the other three.

I don't like plastic materials for environmental and health reasons but the engineering of this frame and fork is extremely impressive.

Oh goodie, another £11k bike!

I'll take two.

Where does a tiny company like Le Monde get the funding to build an entire factory for themselves?

A bit more info here: https://www.wired.com/story/greg-lemond-amazing-candy-colored-dream-bike/

Lost me at "The LeMond 8 frameset is for electronic shifting only."

I'm terms of cycling safety, the bike frame must be somewhere near the bottom.

What you don't know is that there's a vast industry cover-up to prevent news escaping of the swathe of riders killed and seriously injured by their inherently unsafe frames. Road.cc is part of the conspiracy, which is why we don't see any of it reported here, obviously.

Hi and thank you for your comment.

Now, if there is a "vast industry cover-up" over this, no-one has bothered telling this news outlet which is part of the cycling industry and that has a number of journalists with long-standing ties to bike firms and people who know what is going on within the sector.

I've asked my colleagues here whether they've heard any rumours of what you refer to, and none have. It could of course be that they are keeping it from me? Who knows?

If you're able to send any documented evidence to info [at] road.cc, we'd be very happy to take a look at it, including proven cases of "swathes of riders" killed as a result of "inherently unsafe frames."

Thanks in advance.

Simon, I'm sure that comment is a satirical remark, you know, humour.

Great to see that road.cc can go whoosh online at least, as well as, presumably, on the roads!

But above the wheels.

funny.. but the frame encompasses the wheels rather than being above them.