- News

- Reviews

- Bikes

- Components

- Bar tape & grips

- Bottom brackets

- Brake & gear cables

- Brake & STI levers

- Brake pads & spares

- Brakes

- Cassettes & freewheels

- Chains

- Chainsets & chainrings

- Derailleurs - front

- Derailleurs - rear

- Forks

- Gear levers & shifters

- Groupsets

- Handlebars & extensions

- Headsets

- Hubs

- Inner tubes

- Pedals

- Quick releases & skewers

- Saddles

- Seatposts

- Stems

- Wheels

- Tyres

- Tubeless valves

- Accessories

- Accessories - misc

- Computer mounts

- Bags

- Bar ends

- Bike bags & cases

- Bottle cages

- Bottles

- Cameras

- Car racks

- Child seats

- Computers

- Glasses

- GPS units

- Helmets

- Lights - front

- Lights - rear

- Lights - sets

- Locks

- Mirrors

- Mudguards

- Racks

- Pumps & CO2 inflators

- Puncture kits

- Reflectives

- Smart watches

- Stands and racks

- Trailers

- Clothing

- Health, fitness and nutrition

- Tools and workshop

- Miscellaneous

- Buyers Guides

- Features

- Forum

- Recommends

- Podcast

TECH NEWS

2021 Ford derailleur patent - 2

2021 Ford derailleur patent - 2Radical derailleur design revealed in new patent from Ford

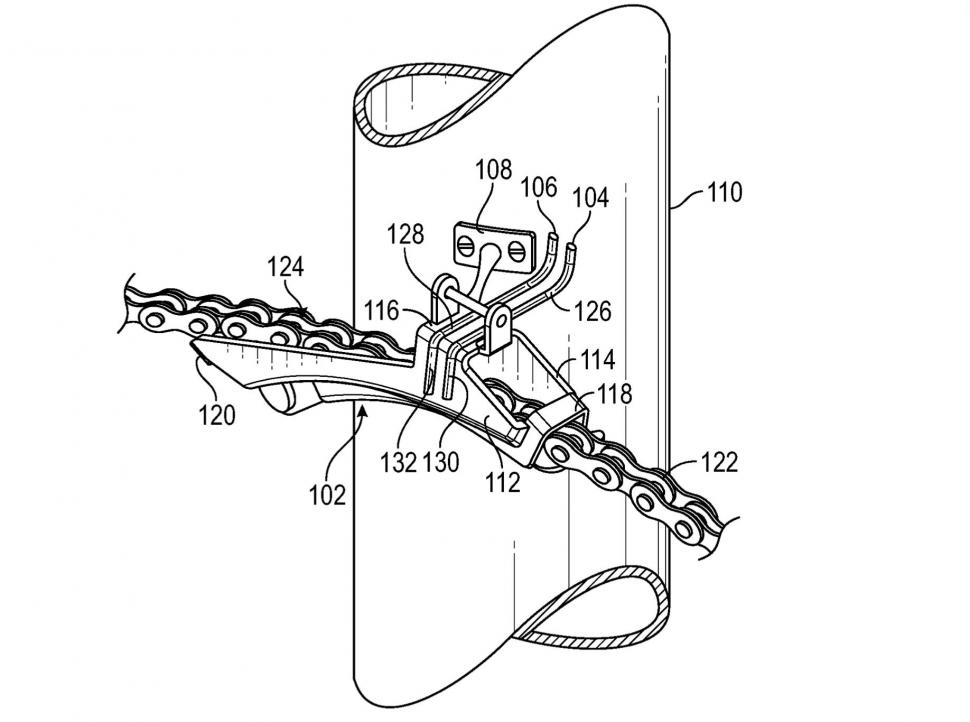

Motor company Ford has been granted a patent for front and rear bicycle derailleurs that work via mouldable wires that bend when an electric current is passed through them. Although seemingly aimed at the e-bike market, the tech could in theory be used for standard bikes.

Wheelbased spotted this patent for a Bicycle Derailleur Apparatus For Controlling Bicycle Speed made by Ford Global Technologies (click here to go to Wheelbased's article), a research and development subsidiary of the Ford Motor Company. The system is unlike anything currently out there.

The system relies on mouldable wire, such as commercially available NiTi Nitinol Nickel Titanium Super Elastic Wire, which is good at deforming and then immediately returning to its original shape. This wire can be given ‘shape memory’ meaning it will take on a different shape when heated and return to its original shape when cooled. Ford says that we’re talking about heats of 100°C, although the wires will be insulated, naturally enough.

The deformation can be controlled by passing electric currents through the wires, causing them to heat up. One of the most attractive features of the design is the lack of parts required. This could reduce complexity, weight, and costs.

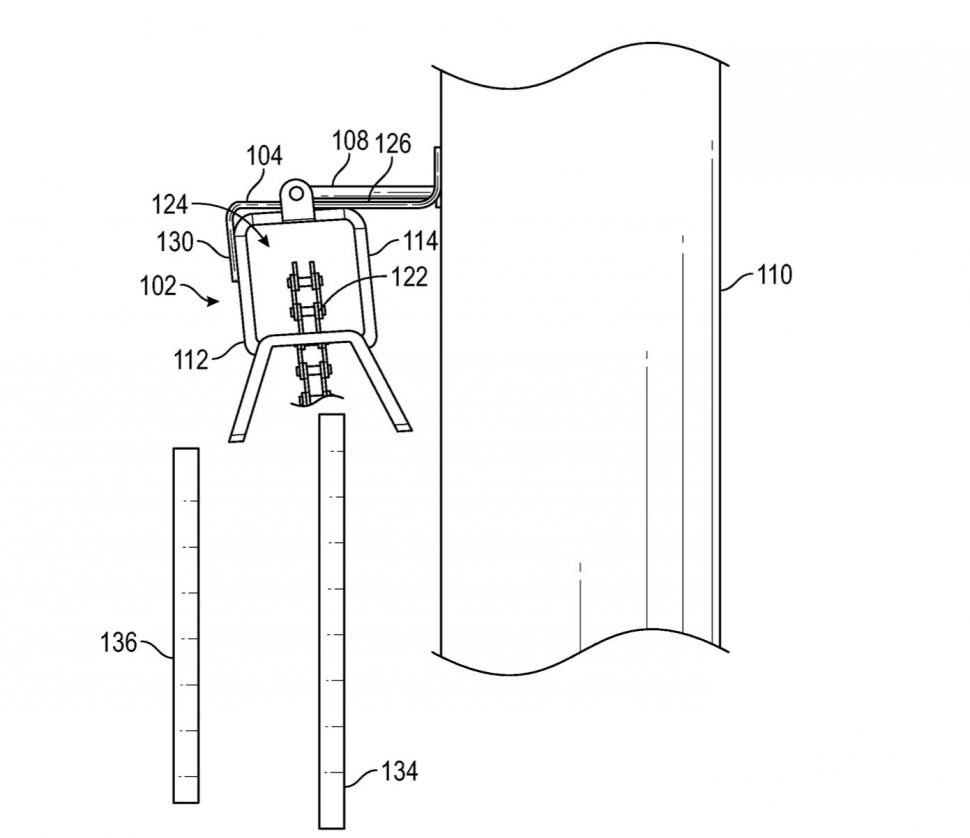

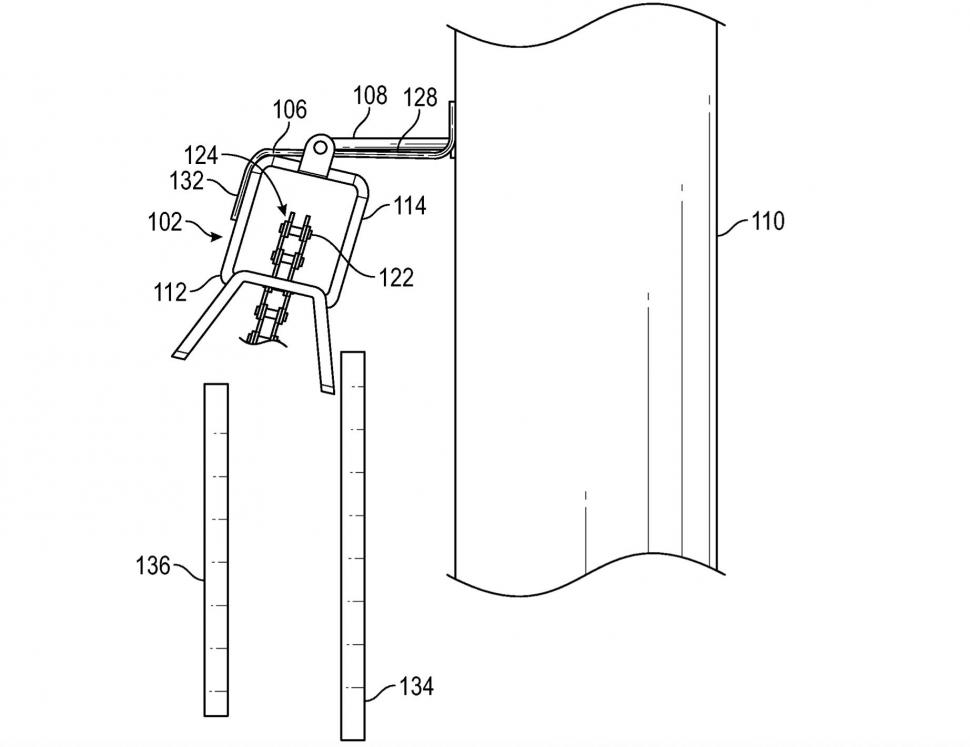

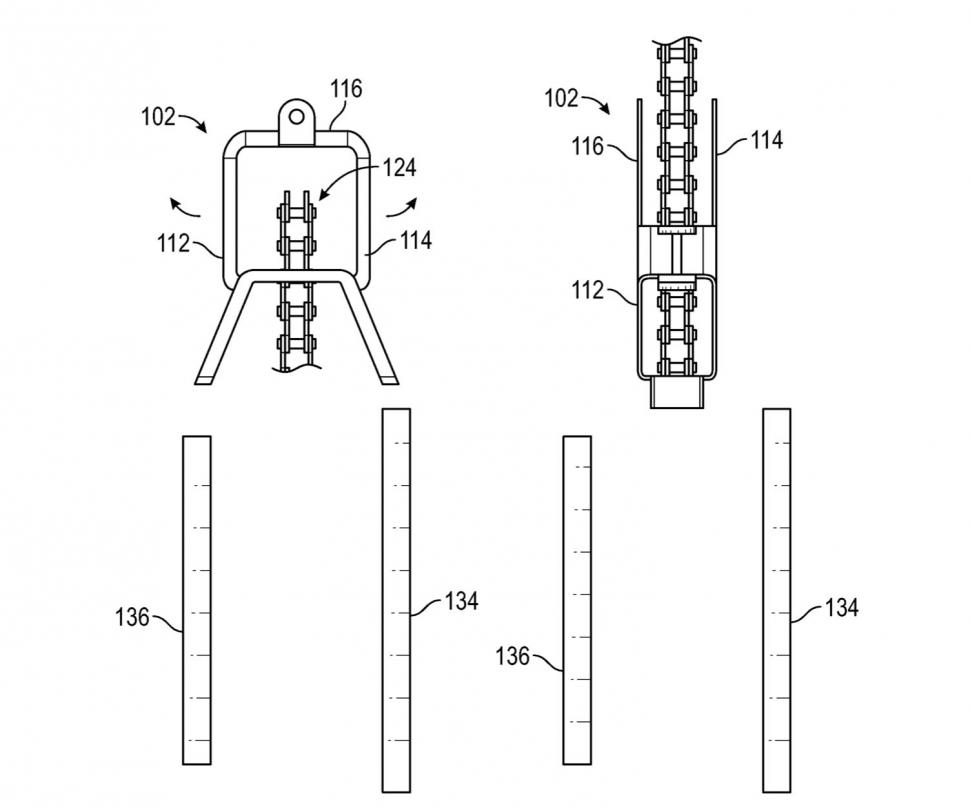

Although the technology is designed for both front and rear derailleurs, let’s stick with the front one here because it’s easier to explain. One possibility relies on two mouldable wires. One end of each wire is attached to the front derailleur cage. This front derailleur cage can pivot inwards and outwards.

Bear in mind that these images from the patent are illustrative of the technology only.

“Upon applying a predetermined electric current to the mouldable wires at separate time periods, the outer end portions deform from pliable states… to respective acute [less than 90°] and obtuse [greater than 90°] angular states.

“As the outer end portions of the mouldable wires are deformed to the respective acute and obtuse angular states… they cause movement of the bicycle chain guide in the lateral direction… to thereby shift the bicycle chain.

“The mouldable wires may push and pull the bicycle chain guide [the derailleur] into engagement with any number of derailleur sprocket gears.”

Make sense?

As is the way with patents, Ford gives a whole load of different design possibilities, the idea being to stop anyone else nipping in with their own variant.

In one instance, for example, “one of the mouldable wires may be attached to the outer wall while the other… is attached to the inner side wall. In this manner, [they] may push or pull the bicycle chain guide as a current is applied”.

In other instances, only one wire would be required. The wire would heat up with the application of an electric current, causing the end section to take on its angular state.

“The predetermined electric current does not need to be constantly applied to the mouldable wires to maintain their respective heated states, but instead may be received periodically so as to maintain the heated states,” says the patent.

What supplies the electric current?

“The bicycle derailleur apparatus may include an electric current generator which may be housed in a pedal crankset or elsewhere, a switch which may be located on the electric current generator to control to which one of the mouldable wires the electric current is applied, and a control panel which may be mounted to the bicycle handlebar which acts like a rheostat [a variable resistor that is used to control current] depending on the desired pedal cadence entered by the rider.

“The rider selects the desired pedal cadence [crank revolutions per minute] on the control panel mounted on the bicycle handlebar or elsewhere… [and] the two mouldable wires will perform the automatic sprocket gear shifting.

“As the rider pedals slower, less current is generated by the electric current generator which is in communication with the pedal crankset. As the rider pedals faster, more current is generated. Based on whether the actual pedal cadence is lower or higher than the selected pedal cadence, the apparatus sends current to the one of the other mouldable wires, depending on whether a downshift or upshift is desired.”

In other words, you could input your preferred cadence and the system would automatically shift to keep you at that rhythm. Remember, although we’ve focused on the front derailleur here (as Ford does in its patent) this technology is applicable to the rear derailleur too where automatic shifts would be less dramatic.

Of course, the existence of a patent does not mean that a launch is imminent or even that a product is being physically developed. As usual, we’ll just have to wait and see whether this one makes it to production.

Mat has been in cycling media since 1996, on titles including BikeRadar, Total Bike, Total Mountain Bike, What Mountain Bike and Mountain Biking UK, and he has been editor of 220 Triathlon and Cycling Plus. Mat has been road.cc technical editor for over a decade, testing bikes, fettling the latest kit, and trying out the most up-to-the-minute clothing. He has won his category in Ironman UK 70.3 and finished on the podium in both marathons he has run. Mat is a Cambridge graduate who did a post-grad in magazine journalism, and he is a winner of the Cycling Media Award for Specialist Online Writer. Now over 50, he's riding road and gravel bikes most days for fun and fitness rather than training for competitions.

Latest Comments

- froze 2 sec ago

Replace those flimsy shutters with steel security bars, or they could use both together with the security bars on the outside of the shutters. ...

- lonpfrb 35 min 32 sec ago

Glad to see they haven't lost the plot on sustainably, oh, never mind...

- Rendel Harris 2 hours 27 min ago

She may have a disability and have the car through Motability. She may have recently lost her job and the car dates from more prosperous times. For...

- bensynnock 2 hours 41 min ago

Southampton?

- TBR 3 hours 39 sec ago

I got myself a klickfix freepack sport with the seatpost mount about 15 years ago which does exactly the same with more distance between saddle...

- wtjs 3 hours 55 min ago

Traffic lights should routinely be programmed to turn red where sensors show speeding drivers are approaching...

- David9694 4 hours 21 min ago

Mum shocked as driver crashes into Helston house in the night...

- Rendel Harris 4 hours 37 min ago

By my reckoning there are eight comments from cyclists who don't think it's necessary, five comments from cyclists who think it's good, four...

- Rendel Harris 5 hours 2 min ago

Well obviously they couldn't touch the central line because there was traffic coming in the opposite direction and so they had to pass you within...

- David9694 5 hours 3 min ago

What are left with, from among the individual builders listed here I wonder, how many are taking orders? https://www.framebuilding.com/custom_uk...

Add new comment

7 comments

I have no interest in Mousers, from Texas Instruments. I will NEVER take a cycling tour with PedalTripr. Not do I care what Cricut makes. I have no interest in Tableau, Wayrite’s shitty clothes, Chubb insurance, or Nicorette FFS.

I subscribed to road.cc to help you make it a better site: ad free to subscribers. When are you going to fulfil your side of the bargain?

Hi Chris, really sorry about this - you're currently not listed as a site supporter, please could you email info [at] road.cc and we'll try to find out what's going on? Apologies again.

As others have pointed out, several serious potential problems with this; speed of response to the current, battery drain, strength of the effect. It takes quite a lot of effort to move a chain from one sprocket to another, just check out the spring strength on derailleurs, so would a single wire produce enough force to do the job?

It'll be heavy on battery if substantial wires have to be heated to 100C. And there will be no adjustability.

A classic example of a speculative patent that has no chance of becoming real.

My understanding :

1. Nitinol is very ductile in one of its states - which means the mech supports will bend easily.

2. I'm unable to find any hard data on this - but I dont believe Nitinol can deform fast enough to move a mech comparably to either a cable or a motor.

I see a problem with number two (speed), especially when we're talking about controlled heating to no more than 100°C. Don't see how it could compete with mechanical derailers or an internally geared system such as Classified's powerhub.

Well, the Ford brand just sparks distrust in my mind from the get go.

I don't know much about shape-changing metals, but they don't seem to have replaced traditional motors anywhere that I'm aware of. Previous alloys tended to wear out extremely quickly (e.g. a thousand uses) but I have heard that there's newer ones that can last for millions of shape changes.