- News

- Reviews

- Bikes

- Components

- Bar tape & grips

- Bottom brackets

- Brake & gear cables

- Brake & STI levers

- Brake pads & spares

- Brakes

- Cassettes & freewheels

- Chains

- Chainsets & chainrings

- Derailleurs - front

- Derailleurs - rear

- Forks

- Gear levers & shifters

- Groupsets

- Handlebars & extensions

- Headsets

- Hubs

- Inner tubes

- Pedals

- Quick releases & skewers

- Saddles

- Seatposts

- Stems

- Wheels

- Tyres

- Tubeless valves

- Accessories

- Accessories - misc

- Computer mounts

- Bags

- Bar ends

- Bike bags & cases

- Bottle cages

- Bottles

- Cameras

- Car racks

- Child seats

- Computers

- Glasses

- GPS units

- Helmets

- Lights - front

- Lights - rear

- Lights - sets

- Locks

- Mirrors

- Mudguards

- Racks

- Pumps & CO2 inflators

- Puncture kits

- Reflectives

- Smart watches

- Stands and racks

- Trailers

- Clothing

- Health, fitness and nutrition

- Tools and workshop

- Miscellaneous

- Buyers Guides

- Features

- Forum

- Recommends

- Podcast

OPINION

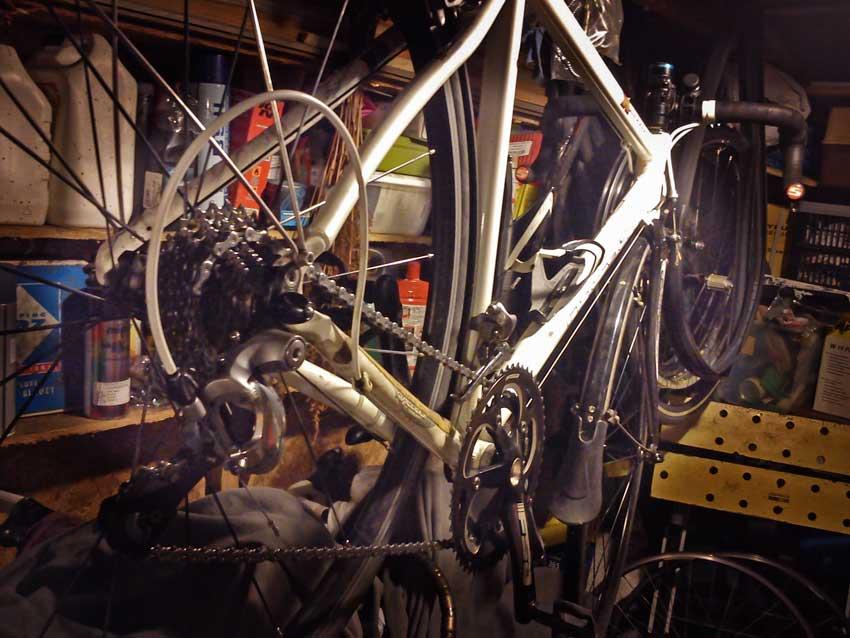

It started with a £1.99 gear inner cable...

Rear-mech-mindlessness

Rear-mech-mindlessnessIt started with a £1.99 gear inner cable. Now I've spent on a new chain, and I'm subsequently googling replacement jockey wheels.

My winter bike hasn't been shifting properly for a while, so what have I done about it? Well, the usual… I've ridden around the problems, clicking the shifter up two to change up one, then shifting back down so that the correct gear is selected in the index system for the corresponding cog on the cassette. With winter coming up, it was time to sort this out, I've had enough of living like a second-class citizen, I mean, correctly indexed gears are a basic requirement for any cyclist.

So, the £1.99 gear cable arrived, then I started getting nervous about re-using the old gear outer, so another couple of quid went on a metre of Jagwire’s finest white outer.

The outer arrived... it was installed... I tweeted about how difficult 105 is to index correctly.

The next thought went to how I’d fallen off last October, knackering my thumb in the process, and how the rear mech (which was less than a couple of weeks old) now bears the scars of that fateful day. Conclusion: the mech hanger must be bent. £13.99 for a new hanger, please!

Mech hanger came... it was installed... I again tweeted about 105 indexing, this time my ineptitude at mastering the black art, and how I much preferred Sram.

Lubing the chain post-mech hanger installation, it looked a bit worn, so thoughts went to putting something fresh on it. One of Shimano’s finest Ultegra specimens duly arrived and has just been flung on.

This time… SUCCESS! Sort of...

Everything’s shifting as it should, I’m not having to put so much tension on the cable that I can see individual strands breaking like something out of a Wile E. Coyote / Roadrunner cartoon, but there’s still something not quite right…

So here I am, googling for new jockey wheels, the ones on the mech look like wonky cart wheels, the total of this quick - “oh, it needs a new cable” – fix is much more than the original two quid, but at least I’m starting to get somewhere.

More Opinion

Latest Comments

- Secret_squirrel 8 hours 2 min ago

Um...no. Spitting is grim and there is never any excuse.

- Another_MAMIL 10 hours 58 min ago

Q36.5 Gregarius Essential Bib Knickers fit the bill: 3/4 length bib tights for warm weather.

- Rendel Harris 11 hours 8 min ago

Jolly good. Only it hasn't been and it is still a public bridleway. Feel free to look it up.

- jaymack 11 hours 58 min ago

"...it feels more like a £100+ jersey". It's almost as if cycling apparel is over priced.

- mike the bike 13 hours 11 min ago

I've had a few Lezyne bits and bobs over the years and while it's true I've never bothered to return anything under warranty, I've had a couple of...

- mark1a 12 hours 14 min ago

There's a transition period. For the benefit in kind (BIK) tax to the employee, it will be treated as a goods vehicle as it is now (rather than a...

- hawkinspeter 13 hours 22 min ago

Parents say East Bristol Liveable Neighbourhood makes roads '100 times safer' for children:...

- mdavidford 13 hours 28 min ago

Isn't basically all carbon recycled? From stars?

- velodinho 14 hours 44 min ago

As witnessed at so many infrastructure improvement projects similar to this one, all those who object should ignore the consultation and pray at...

- Nagai74 16 hours 32 min ago

It's a DLO to those in the trade.

Add new comment

19 comments

I know Tiagra has those dorky indicators, but really, with an entire groupset available around £300, you can't go wrong. Sweet shifting and if you break anything the parts are much more reasonable.

I've built up two bikes now (one compact, one triple) and both have worked fine right off. Shifting sets up in ten minutes, with the front derailleur being the most finicky. Ride a hundred miles and fine-tune.

I've got bikes with 105, Ultegra and Sram Apex/Rival/Red, and for the price, you can't beat Tiagra. Broken Sram shifters = heart attack.

I agree entirely,Tiagra are splendid.

Initially I was reading all the problems about 105 indexing with a "the fuu?" expression - as I have Ultegra from new, on a new bike and had little problems with it, or rather in recent memory...

Then I remembered about my disappointment on switching to 105 STIs/Ultegra RD on a different bike and the number of things I tried - none of which worked. Cables were all new etc, but I had a problem with the middle of the cassette and I put it down to the mech hanger after all this time based on replies from a "good ol bike shop", comments on here as well as having exhausted all other possibilities!

Going back to Ultegra on the new bike - it was flawless, absolutely 100% on the first few rides. Then I had one wet ride after which the shifting was just completely different - shifting out of saddle under load - either way, was pretty scary as there would be big jerks through the pedals as the chain did not engage fast enough. After some time though it became fine and also having switched to SRAM chain and cassette that took my mind off it.

Recently though, I decided to try going back to Shimano cassettes just for a bit of change. I went with a KMC chain and initially had some quite alarming jerks on shifts either way. Having checked things in the usual fashion I just decided to leave it. After maybe 1k it all was fine again. So the bottom line at least from my experience is that Shimano cassettes take a pretty long time to bed in compared to SRAM which seems to work the same throughout the lifespan. Now I would be inclined by the price rather than brand.

In the end the point is that maybe all the people that are having trouble with settings up 105 might just need to leave it for a bit, omitting any hanger problems. Trust me though, I know how tempting it is to fiddle with the cable tension if there are a few suspicious shifts!

I strip and clean my bike every week, it's always better to prevent problems rather than having to solve them. Well worth the effort if you have time and VERY therapeutic. .

.

My 105 has seen 6000+ miles with only one new chain. A well set up and maintained bike will just keep going if you treat her right

I gave up on Shimano STI shifters ages ago. They are effectively expensive, throw-away gadgets. The routing under tape is a joke.

I use bar end shifters on custom mounts and full outer casing.

As ergonomic as STIs but much more reliable and more economical in a longer run.

@hampstead_bandit - couldn't have put it better myself ... so I didn't

Shimano 105 is not difficult to index as long as derailleur hanger is in alignment, cabling in good condition and drivetrain parts not too worn (specifically the rear derailleur does not have excess slop in cage pivots, bent cage, or over-stretched tension spring)

if that hanger is slightly bent, or cage bent, pivots sloppy, you will not be able to get reliable shifting across the entire cassette.

Having the chain slip under power (generally in smallest rear cog i.e. 11T) is a different matter, as this setup will generally work fine on the workstand in terms of indexing, but once a rider puts some load onto the chain it can slip.

the hanger alignment tool is money well worth spending, as others have mentioned. Also, don't assume a new derailleur hanger is actually straight, especially the OE "brand" hangers which are cheap cast items - its always better to use a CNC machined hanger from Wheels or North Shore Billet, etc.

cabling is another critical issue; many brands use cheap OE cable from Jagwire, etc. which can use issues like 'shifting lag' where you can get a reliable up shift, or down shift, but not in both directions!

I'd always use Shimano SP-41 for 10 speed road bikes (either for Shimano or SRAM drivetrains) and genuine Campag for Campag drivetrains. Pay attention to cable length (especially rear loop into rear mech) and cable prep / finishing when installing.

professional bike mechanic and workshop manager

Ditto re. Changing down two to shift down one, then up one. SRAM Apex though so not exclusive to Shimano!

It's damn pricey at circa £60, but every serious home mechanic should own a rear hanger alignment tool. If your hanger alignment is out by an amount too small to see with the naked eye (esp. against a set of dished spokes) , you will never get the shifting perfect. Park recommend no more than 4mm out at the 12, 3, 6 & 9 positions - that is ***impossible* to tell at the 3 & 9 with just a few mm either side of the mech bolt hole, and damn near impossible at the others.

It's on my "to buy" list. This year's birthday present was a rear wheel dishing tool. Slowly populating my specialist tools section bit by bit!

Actually, every rider should have a friend with specialist tools. Or, given the infrequency with which we use them, buy them alternately.

Btw, wet here in Auckland this afternoon, but warm rain. I'm impressed with you Brits riding in weather which is cold, wet and even icy. I used to ride in winter in Toulouse, but it gets little rain, so was more bearable.

There is only one solution. Di2, you know it makes sense and by the time you have replaced all the other bits and still not got where you want you will have spent at least 10% of the cost of the Di2 anyway

Di2 Alfine... http://road.cc/content/news/53529-shimano-launch-alfine-di2

The ultimate fit-and-forget?!

A new set of jockey wheels was the saviour, along with replacing the other worn-out elements mentioned in the blog.

Now shifting like an absolute dream!

Nothing like the satisfaction of sorting out a problem!

cycling.fan - well done on the self-build. It does take a while but it's worth it when you get it all right.

Cable tension should not need to be that thight to get everthing working smoothly - in fact the more tension, the more friction in the system and so the more likely to have problems!

There are many things that can cause poor shifting performance and you have addressed some... but have you done them properly? With the new outers are they the right length? Do they follow smooth arcs from point to point?? Are the ends finished properly.... and square???

With your new gear hanger are you sure it is straight to the FRAME mount???

Is your wheel ALWAYS mounted fully square to the frame - chain tensions can easily pull it out of line during fitment. Is your rear mech worn????

Has your cassette been mounted using the correct torque to much / to little and the 'free' cogs may not be sitting properly / square. Is there any play in the freehub bearings that causes it to rock?

Are you using 'matched' components????

These are all things that a good mechanic can do / check / set up for you. Yes the prices may seem a bit steep sometimes, but often it can work out cheaper in the long run.

guys, there are some really good sources for tuning and installing bike stuff.

here is the site i personally found useful. see Sol's videos on Utube.

http://www.youtube.com/user/velotique

http://www.velotique.com/clinic-r.htm

another source that also helped me (if you do self installtion).

http://vimeo.com/search?q=shimano+installation

i started riding bicycles in 2006 (not though extesnively due to lack of time). in 2008 i experienced the first problem - rear shipfting. the very first problem required me riding around an empty parking lot, back and forth, and 40 minutes to get all 10 gears to work properly both ways - shifting up and down. again, all info sources were found in internet. i live is a small town in central asia, there are no LBS or good shops, or people who understand something in bike repair and tuning. at least i don't know. and not many road bicycles here or lads who ride them.

in march 2012, i first time upgraded my bike completely on my own (thanks to Chain Reaction Cycles and Amazon) and thanks to the internet sources.

after that in november 2012 i did change some parts again. my bicycle is Giant Defy Advianced 3 of 2009. in April 2013 i did help my farther to replace his bent hadnlebar (Giant cyclocross bike). u should understand that changing handle bar requires removing and remounting shift and brake cables again. what i have understood:

whatever you do, (unless a certain component has a manufacturing defect, or was bent or broken due to fall or collision), one can still do tuning or installation using only internet sources. the only drawback requires lots of free time and patience especially if you do it first time. again, my bike is road bike, so all installations and tuning done by me have been using road bike components. let me know if you want to see a picture of my bike how it looks now.

yeah the 105 can be a right SOB to index. Oh but once its done its sweat

Oh no, you're scaring me. My bike isn't shifting into the bottom two gears. I've had a brief play with the cable tension to no avail. Argh, I hate it when my bike's not working and hate repairing it yet hate taking it to the LBS and trusting them to do me proud (they usually do though!). One day I'll get around to it, until then, I can live without those bottom two gears!

Have you changed the handlebar outers too? Might not seemklike it's wornas hey, it'sionly under the barttapeaway ffrom all dirt but can make a pretty big difference!