- News

- Reviews

- Bikes

- Components

- Bar tape & grips

- Bottom brackets

- Brake & gear cables

- Brake & STI levers

- Brake pads & spares

- Brakes

- Cassettes & freewheels

- Chains

- Chainsets & chainrings

- Derailleurs - front

- Derailleurs - rear

- Forks

- Gear levers & shifters

- Groupsets

- Handlebars & extensions

- Headsets

- Hubs

- Inner tubes

- Pedals

- Quick releases & skewers

- Saddles

- Seatposts

- Stems

- Wheels

- Tyres

- Tubeless valves

- Accessories

- Accessories - misc

- Computer mounts

- Bags

- Bar ends

- Bike bags & cases

- Bottle cages

- Bottles

- Cameras

- Car racks

- Child seats

- Computers

- Glasses

- GPS units

- Helmets

- Lights - front

- Lights - rear

- Lights - sets

- Locks

- Mirrors

- Mudguards

- Racks

- Pumps & CO2 inflators

- Puncture kits

- Reflectives

- Smart watches

- Stands and racks

- Trailers

- Clothing

- Health, fitness and nutrition

- Tools and workshop

- Miscellaneous

- Buyers Guides

- Features

- Forum

- Recommends

- Podcast

TECH NEWS

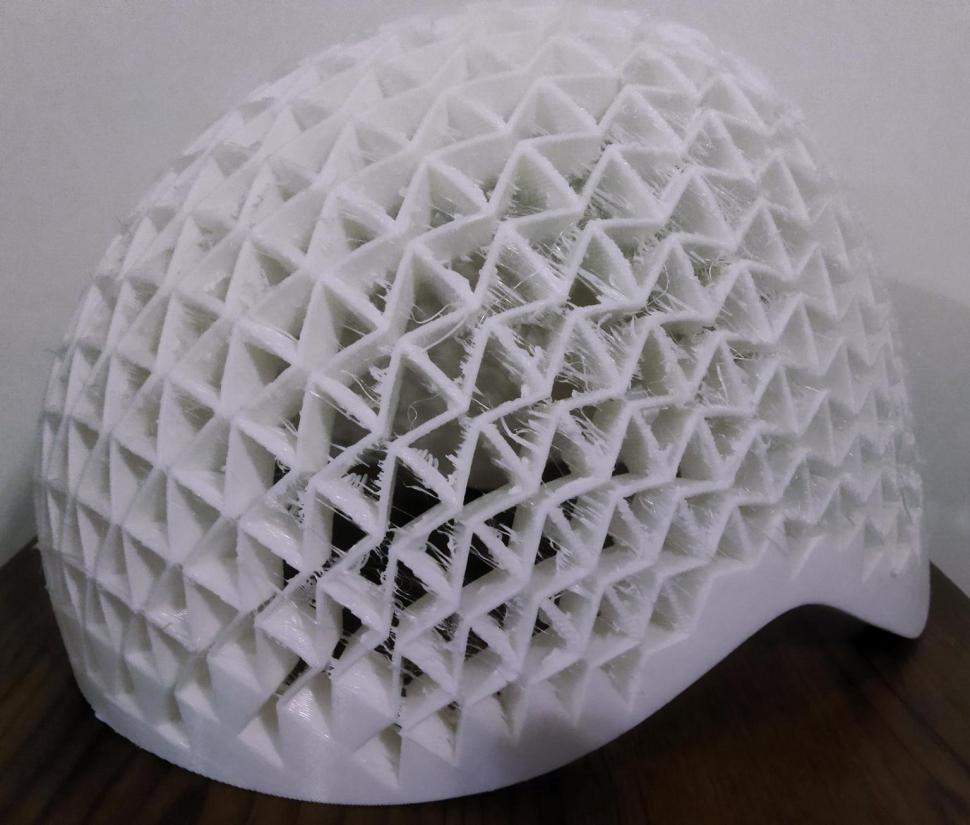

University of Gothenburg helmet design (credit: Mohammad Hossein Zamani/University of Gothenburg)

University of Gothenburg helmet design (credit: Mohammad Hossein Zamani/University of Gothenburg)New 3D-printed cycling helmet could be 'safer, lighter and more comfortable', but researchers admit design still needs more comprehensive testing

"With further development, this technology could lead to a new generation of bicycle helmets that are safer, more comfortable and more customisable."

That is the claim of University of Gothenburg researchers who have this month unveiled an "innovative" new helmet design made with 3D-printed "auxetic metastructures" that offer "better protection" and come in lighter than current products.

Not got a clue what an auxetic metastructure is? Don't worry, we'll get to that in a second. Although maybe we should temper the claims of the paragraphs above by also mentioning now that the study concludes by admitting that, while testing and numerical simulation results do currently "meet the standard requirements", any further implementation will necessitate "a comprehensive testing protocol".

This should include, the academics admit, "testing multiple helmets under repeated impacts at varying angles and velocities and across a range of environmental temperatures, adhering to the relevant standard". So we're not at the finished product just yet, even if Mohsen Mirkhalaf (an associate professor of mechanics and physics of materials at the University of Gothenburg) and his team are confident we could be at some point in the not-so-distant future.

So, back to the question on everybody's lips — what is an auxetic metastructure and why is it relevant for what I put on my head when I go for a bike ride?

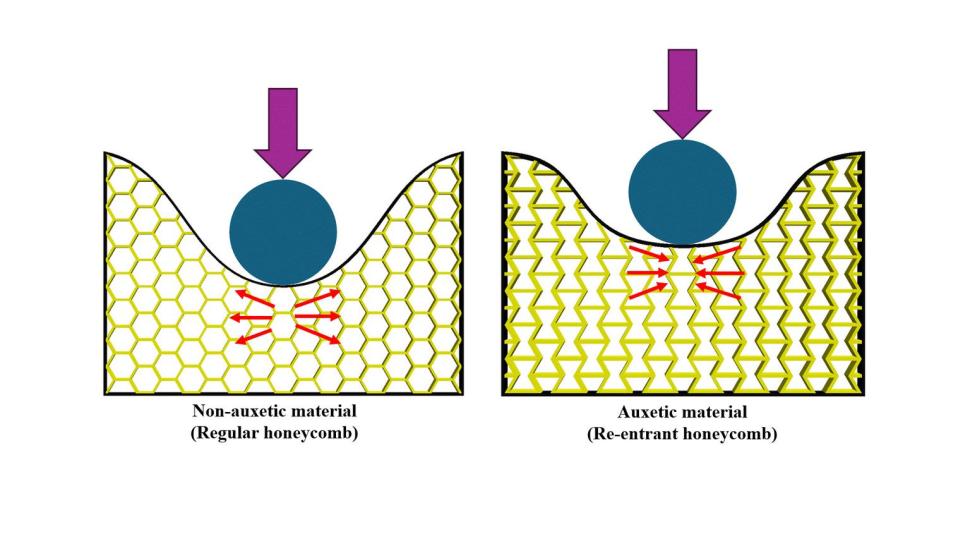

Thankfully the paper — 'Design, optimization and additive manufacturing of an innovative bike helmet using auxetic metastructures', published in the International Journal of Solids and Structures — offers the diagram below to demonstrate the concept but, in short, it refers to the design of the helmet whose "honeycomb" shock-absorbing material is designed in "special geometric patterns that behave differently under impact conditions compared to conventional foam liners".

We've seen this sort of thing before, for example the Hexr helmet which used a 3D printed honeycomb construction that independent testing says performs 26 per cent better than the average lid.

Then there was Bontrager's WaveCel tech with its layers that "move independently and flex until the cell walls crumple and then glide, actively absorbing direct and rotational energy and redirecting it away from your head".

We put these examples to Mirkhalaf and asked what exactly the difference was between their idea and the already established products, something he said was down to the use of an "auxetic metastructure", coming back to the earlier diagram comparing it to other 'honeycomb' designs.

"Auxetic metastructures have been shown to offer enhanced energy absorption capabilities compared to conventional structures," he said. "This is highly relevant for a helmet and helps to develop safer helmets because they can absorb impact energy better.

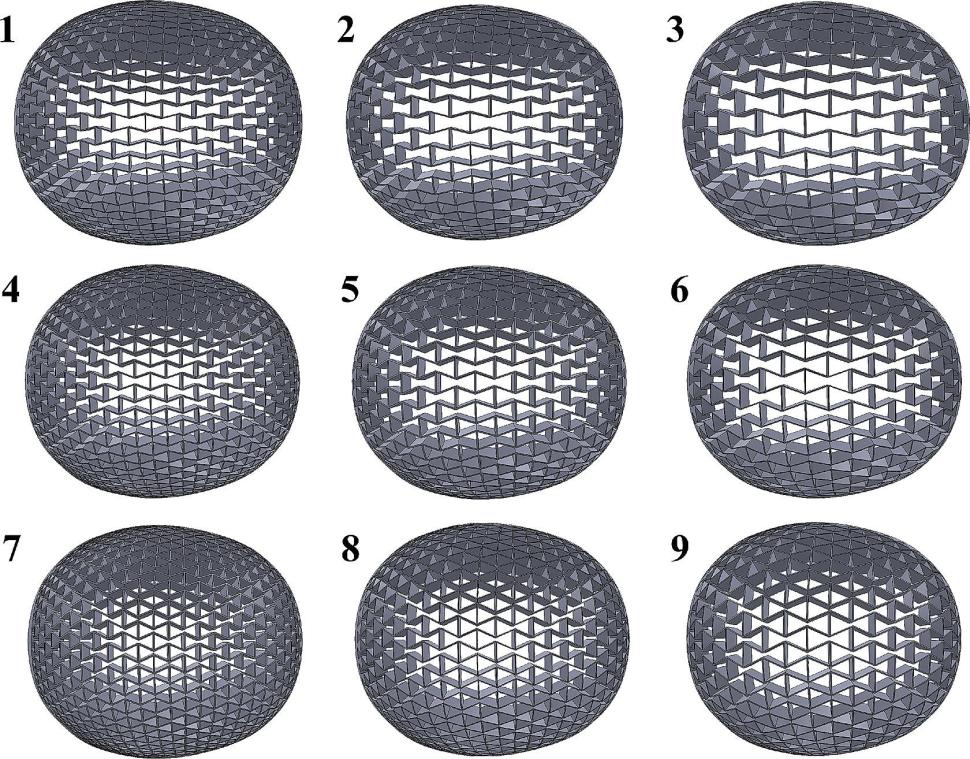

"When exposed to energy from an impact, the liner material contracts, and this improves the absorption of impact energy, which means lower risks of injuries to a cyclist's head in an accident," Mirkhalaf explains, the process seeing nine design structures with the suggested dimensions created and subsequently simulated through helmet impact tests.

"We used a specific design optimisation method to identify the best possible geometric configuration to minimise crash forces. The geometry of the material structure is a key factor."

The designs' impact tests were carried out on a flat and kerbstone anvil, the paper concluding that "both the experimental test and the numerical simulation results meet the standard requirements", which demonstrates the auxetic liner "is able to effectively absorb and dissipate energy, providing adequate protection to the wearer".

Naturally, as this is just the initial design for a helmet liner, there is plenty more work to be done to produce a final helmet which would, of course, then need the "comprehensive testing" the researchers admitted would be necessary. They suggest the next step would be to manufacture their design using a TPU material and the helmet shell using a PETG material with a 3D printer.

You would then need all the finishings, such as the strap, and the whole thing constructed, the researchers noting that due to the geometry and angle of the liner, there would be "no need to use glue for the connection".

Because of the subject matter the headline act is always going to be the safety claims, Mirkhalaf and his team suggesting the design has "the potential to enhance energy absorption and reduce the risk of head injuries" and their findings can "provide valuable insights" for helmet manufacturers, researchers, and regulatory bodies.

> Should you buy an aero road helmet?

However, he also sees performance and comfort gains too, with potential for lighter, more comfortable and more customisable helmets thanks to the material and 3D-printing involved, which means designs could be customised to an individual's head shape and benefit users who struggle to find a comfortable lid that works for them.

"The knowledge of auxetic metastructures that expand laterally when stretched has been around for almost 40 years. However, development of different metastructures has exploded due to the advancements in 3D-printing technology," Mirkhalaf said.

"With further development, this technology could lead to a new generation of bicycle helmets that are safer, more comfortable and more customisable. Although 3D-printing technology currently is more expensive than mass-produced foam liners, costs are expected to fall as the technology becomes more widely used. In the future, it may even be possible to have personalised helmets printed on demand, ensuring that each rider receives the best possible protection."

It has been a news-heavy week for helmet tech. On Monday, we brought you a look at British brand Venete's aH+1, an inflatable helmet that is said to deflate to 10 per cent of its inflated size, making it more compact than a laptop when stored.

It will set you back £350, including the pump, and Venete says it meets full EU and UK certification standards, although many of the figures cited in its study relate solely to linear risk. Our review will be going live shortly.

Dan is the road.cc news editor and joined in 2020 having previously written about nearly every other sport under the sun for the Express, and the weird and wonderful world of non-league football for The Non-League Paper. Dan has been at road.cc for four years and mainly writes news and tech articles as well as the occasional feature. He has hopefully kept you entertained on the live blog too.

Never fast enough to take things on the bike too seriously, when he's not working you'll find him exploring the south of England by two wheels at a leisurely weekend pace, or enjoying his favourite Scottish roads when visiting family. Sometimes he'll even load up the bags and ride up the whole way, he's a bit strange like that.

Latest Comments

- ChrisA 12 sec ago

Balance bike: £600 - brakes extra.

- LeadenSkies 19 min 30 sec ago

As a non local who occasionally has to cycle from St Ives to Cambridge, at a sedately average speed of 12mph, I have had to use alternative routes....

- don simon fbpe 2 hours 1 min ago

I'd go for 'the sun was in my eyes' as a defence, get away with murder with that one...

- PRSboy 3 hours 45 min ago

I have two aero bikes- an Argon18 Nitrogen and an Orro Venturi. I love the way they feel on the road. I also like the style of the deeper section...

- Rendel Harris 11 hours 22 min ago

They have here: results at 14.40. The aero bike was roughly fifteen seconds faster than a climbing bike on a descent of around 6 km, so about 3km/h...

- wtjs 11 hours 36 min ago

As I've also placed here the nutter Audi and white van drivers, I've decided to give those no-nonsense keep-the-country-moving BMW drivers a list...

- polainm 12 hours 39 min ago

100% this. Policing mentality is formed by social 'norms', and the cyclist witchhunting across social media is the UK norm. Close passing a person...

- David9694 14 hours 4 min ago

That's a clear 2 points awarded there, but I guess as there's now a 25% tariff you'll only get 1.5

- mark1a 14 hours 15 min ago

Fawkes Cycles is only local if you live near Oldham. That's nearly 300 miles away from me. Also, any retailer that doesn't participate in an...

- David9694 14 hours 17 min ago

Openreach under fire over delays to Amesbury cabinet repairs...

Add new comment

7 comments

Having experienced a brain injury (while my helmet only suffered a little crack) I welcome all this excellent research which looks for ways to absorb the energy from a fall rather than pass it through your cranium and into your brain. At the moment WaveCel seems to be the best but I look forward to any new technology that is both efficient and affordable.

Not sure if I missed it but I didn't see anything about aero gains, weight savings and they didn't look that "cool" either???

As for £350 for a blow up helmet - that must be the epitome of "inflated pricing!"

I'm surprised there hasn't been a move to "Rollerball" (1975) given the epidemic of street thefts and ongoing "war on cycling."

Not clothing but haven't there have been a couple of spiked wing mirrors shown here? And the poster who's added some plastic pipe to their bike like Leonardo's war chariot.

glad the article mentions that the knowledge of these auxetic structures has been around for 40 years and that it is a suite of developing 3d printing technology and manufacturing processes that are allowing researchers to apply this to this particular new context. It is what good research innovation is about. New knowledge and techniques will emerge whether or not this helmet sees the light of day. You can also foresee that the structures could also be applied to other clothing areas or wearable protection as well as crash structures.

It's great to see this sort of innovation but it's always worth reminding people who say helmets should be mandatory that most cycling fatalities are due to crush injuries to the upper torso.

Helmets make a contribution to reducing injuries and deaths but the only real solution is to separate bikes from vehicles.

Yep.

Helmets are a discussion re-minor injuries, not serious or fatalities...

See current research for skiing - massive reduction (70-80%) in all head injuries. No reduction in serious or fatal head injuries; Turns out helmets are great for stopping people slicing themselves open on ski edges or getting nasty rashes from icy piste that bleed heavily so need a bloodwagon, but are completely useless for people smashing into other skiers or trees/rocks off the side of the piste; Has far better data than cycling, because they can track helmet usage and already track milage + accidents against ski passes (photos from lift gates to identify helmet usage (existing photos to check passes aren't shared); milage directly correlates to lift usage)

And of course road cycling, while offering the same protection from helmets (see multi-standard helmets), has a far greater proportion of serious vs minor (fewer people falling over while riding on tarmac roads vs skiiers falling on pistes).

If you need to keep peak impact acceleration below X (what helmets are designed to do) then no matter how good the tech is, the limit is the distance you crumple over; The only way to make helmets significantly more protective is to make them much, much bigger to spread deceleration over a longer distance; Which has its own issues (neck strength, rotation injuries from leverage, perioception/larger impact areas meaning head impacts that would have otherwise been avoided by tucking in, etc)

This takes me back. I remember auxetic foam being demonstrated on Tomorrow's World back in the 1980s.