- News

- Reviews

- Bikes

- Components

- Bar tape & grips

- Bottom brackets

- Brake & gear cables

- Brake & STI levers

- Brake pads & spares

- Brakes

- Cassettes & freewheels

- Chains

- Chainsets & chainrings

- Derailleurs - front

- Derailleurs - rear

- Forks

- Gear levers & shifters

- Groupsets

- Handlebars & extensions

- Headsets

- Hubs

- Inner tubes

- Pedals

- Quick releases & skewers

- Saddles

- Seatposts

- Stems

- Wheels

- Tyres

- Tubeless valves

- Accessories

- Accessories - misc

- Computer mounts

- Bags

- Bar ends

- Bike bags & cases

- Bottle cages

- Bottles

- Cameras

- Car racks

- Child seats

- Computers

- Glasses

- GPS units

- Helmets

- Lights - front

- Lights - rear

- Lights - sets

- Locks

- Mirrors

- Mudguards

- Racks

- Pumps & CO2 inflators

- Puncture kits

- Reflectives

- Smart watches

- Stands and racks

- Trailers

- Clothing

- Health, fitness and nutrition

- Tools and workshop

- Miscellaneous

- Buyers Guides

- Features

- Forum

- Recommends

- Podcast

beginners toolkit guide

beginners toolkit guideHow to build your own bike toolkit, a beginner's guide — must-have tools for cyclists to carry out basic repairs

Getting start as a home cycling mechanic doesn't require a vast toolbox filled with every bike-specific tool imaginable. In fact, many essential tasks can be tackled with just a few good quality standard tools and a couple of bike-specific ones. In this guide, we'll cover the must-have tools for your toolkit that will help you become more self-sufficient with your bike maintenance. There's also some linked to tool-specific buying guides, so you can easily find the right tools for the job and your budget.

Building up your own bike tool kit lets you fix those little niggles that come up regularly and, over time, you’ll almost always save money compared to paying for servicing.

With the right tools, there are loads of jobs you can tackle from your own home, though the specific tools you'll need depend on the types of things you're prepared to do. Each bike’s different, but there are many tools common to almost all bikes. Bear in mind also that the adage ‘buy quality, buy once’ really does apply when it comes to bike tools. Good tools work better, last longer and are less likely to damage the parts you’re working on. Think of them as an investment, not a cost.

Having a tool kit doesn't mean you have to do everything yourself, and we're by no means here to discourage you from taking your bike to an experienced mechanic at your local bike shop when the situation calls for it. Attempting a 'big job' by yourself with little experience could end up costing you more than paying a professional, so choose you battles wisely.

> How to keep your bike running smoothly

Plenty of us here at road.cc still use our bike shops regularly, as investing in specialist tools you're only going to use once or twice a year sometimes isn't economical. On the other hand, buying some good Allen keys to tighten things, or a decent pump and tyre levers to fix a puncture, will start to pay off very quickly.

It's worth noting that this guide isn't for experienced home mechanics with a pro mechanic-level bike toolkit, and the tools listed here will not handle every mechanical emergency. Instead, it's designed for those who are just starting out or are ready to move beyond relying on their local bike shop, and begin tackling some basic maintenance tasks on their own. Still, if you fit into the former category and are still reading this, feel free to pop any advice in the comments.

Of course, another option instead of purchasing individual items is to buy a ready-made tool kit. Some kits include many tools that you may not necessarily need, so we recommend looking for one that includes items listed below.

Without further ado, here are some essential tools to consider investing in for those simpler tasks that will help you get started...

Workstand

First and foremost, if you're going to do any work on your bike, whether it's a simple adjustment or a bigger repair, a workstand is an essential piece of equipment. The good news is, you don’t have to spend a fortune to get a good one either.

Being able to hold your bike steady and clear of the floor makes any job easier and your back will thank you for not leaning over a bike for hours on end too.

Allen keys

A good set of Allen keys are simple to use, and will allow you to carry out a wide range of adjustments, since many components on bikes rely on hex bolts. If you can only have one set, we recommend opting for a set like the one above, featuring a ball-end on one side for easier access to hard-to-reach places, as well as a straight end to help prevent rounding off bolts.

Unlike standard Allen keys, which only work when inserted straight into a bolt, ball-end Allen keys have a rounded tip that allows you to turn a bolt from an angle, making it easier to reach awkward bolts, like mudguard mounts on the inside of fork legs, speeding up many jobs.

Don't skimp on Allen keys, as you'll be using them a lot. As well as being harder and more accurately made, and therefore less likely to mash the bolts you tighten with them, high-quality keys have a narrower neck for the ball, and therefore work at steeper angles, making them more versatile.

Torx keys

> 8 upgrades I've made to my road bike to make it better than a new one

It may well be that not all bolts on your bike are compatible with Allen keys, especially if you ride a newer bike, so you may need a set of Torx keys as well. Torx fittings are becoming increasingly common on bikes, and like Allen keys, they come with both plain or ball-end versions.

Torx keys have a six-pointed, star-shaped tip that often provides better torque transfer than Allen keys, reducing the risk of slippage and minimising the chance of rounding off your bolts.

Torque wrench

Like Allen keys, a torque wrench is a vital tool for handling most bike maintenance tasks. Most bolts on bikes, particularly carbon bikes, have a stated torque tolerance. A torque wrench helps prevent the risks of over-tightening, which can be costly and dangerous. With a torque wrench, you can get the bolts on your bike as tight as they need to be and — importantly — no tighter.

Over-tightening can strip threads, damage components, or even cause them to fail, while under-tightening can lead to parts coming loose, which can also be dangerous. By following the manufacturer's recommended torque settings, you can avoid these issues.

Torque wrenches don't have to be expensive either. For example, Ritchey offers a torque key with 4 or 5Nm settings, ideal for tasks such as adjusting stem and seat post bolts.

Pedal spanner

Depending on what pedals you have, it may also be worthwhile adding a 15mm pedal spanner to your growing collection of tools. If you look at your pedals from the inside of the cranks and there's a hexagonal socket on the end of the spindle, you will likely need an 8mm Allen key.

Pedals can be notoriously stubborn, and it's worth remembering that one of them has a reverse thread so that it doesn't undo when you're riding along. A proper pedal spanner will give you a better chance of leveraging off pedals, and is usually thinner than a regular spanner to fit between the pedal and crank arm. A standard 15mm spanner will fit some pedals, but others need the thinner jaws of a specific pedal spanner.

Chain wear gauge, chain tool and quick link pliers

> How to clean your bike chain

You can keep an eye on the wear of your chain by measuring its length over 12 full links with a good quality ruler (or 10 if yoiu prefer metric measurements). If it’s stretched by 0.5% on an 11- or 12-speed chain it's time to replace it, and on 10-speed or below you can get away with 0.75%. A wear gauge makes this easier by telling you when your chain needs ditching. You don't need a specific tool for this job, but at a few quid you might as well.

If you want to then replace your own chain, you'll need a chain tool to remove excess links to get the right length for your bike. Most new chains come longer than needed, so you'll need to shorten it by pushing out the pins with the chain tool. You'll need to check that the chain tool is compatible with your chain though.

> Do you need a new chain? Find out the easy way to tell

Adding a quick link to your chain can be incredibly handy. A quick link replaces a chain link with a pair of interlocking plates with in-built pins that can be installed or removed without a chain breaker.

You can open a quick link without a dedicated tool, but using a pair of quick link pliers will make this process much easier.

It's also useful to carry a spare quick link with you on rides in case your chain snaps. You can then make a quick roadside repair with the quick link and complete the ride. For some more tips on what to tools to take with you on your rides, check out our cycling essentials guide.

Cassette tool and chain whip

As you gain more experience with bike maintenance, adding a cassette tool (also known as a lockring tool), and a chain whip to your toolkit can be quite beneficial. Although you might not need to replace your cassette frequently, these tools are essential for removing and installing it.

The chain whip helps hold the sprockets in place while you use the cassette tool to remove the lockring that keeps the sprockets together on your bike's freehhub.

Cable cutters

If your bike has brake and gear cables, it's worth getting a proper set of cable cutters with blades shaped to keep the cable strands together.

Do not try and cut cables with pliers, scissors, sidecutters or any other vaguely sharp snippety-chop tool you have kicking around, as you'll just make a mess of them.

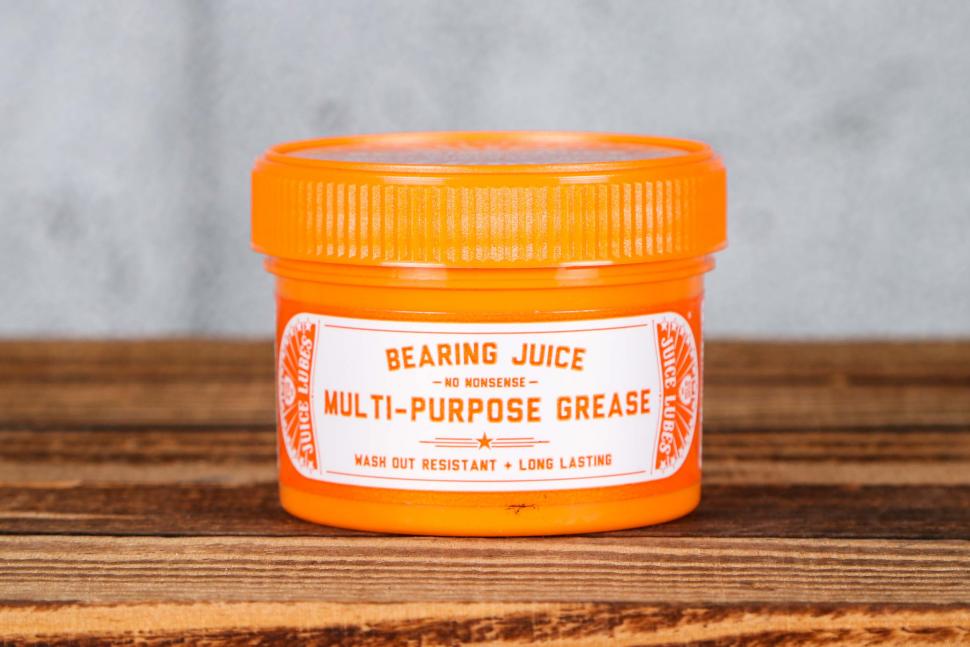

Grease

This next one isn't a tool as such but a grease or anti-seize compound is essential for any jobs that you are going to be carrying out that require tools.

Grease is key for reducing friction and preventing wear on moving parts, like bearings, pedals and the threads of bolts, while anti-seize helps to prevent components from seizing up or corroding like bottom brackets, seatposts or pedal threads.

Electrical tape

Again, this isn’t strictly a tool, but to secure small bits, stop annoying rattles from inner tube valves, and finish off applying bar tape, it’s worth having some decent electrical/ insulation tape - preferably in black!

What’s your top toolkit essential? Let us know in the comments section below.

Emily is our track and road racing specialist, having represented Great Britain at the World and European Track Championships. With a National Title up her sleeve, Emily has just completed her Master’s in Sports Psychology at Loughborough University where she raced for Elite Development Team, Loughborough Lightning.

Emily is our go-to for all things training and when not riding or racing bikes, you can find her online shopping or booking flights…the rest of the office is now considering painting their nails to see if that’s the secret to going fast…

Latest Comments

- Geoff H 21 sec ago

I was really enjoying the article until I came to the price!

- OldRidgeback 53 min 22 sec ago

I have a very old MTB (guess what make) that I'll happily leave locked at the train station or shops or whatever. The fairly new Trek MTB or...

- TheBillder 2 hours 28 min ago

Dualling that stretch of the A7 will allow hard-pressed motorists to travel very slightly faster between the rock that is the Sherriffhall...

- BikingBud 2 hours 35 min ago

I refer to being an engineer only to emphasise my consideration of the logical approach that should be applied in the justice system, rather than...

- chrisonabike 4 hours 4 min ago

But is it compatible with elliptical chainrings?

- David9694 4 hours 6 min ago

Parking fail as car left teetering on top of stone wall Oh dear https://www.devonlive.com/news/local-news/parking-fail-car-left-teeterin...

- jaymack 5 hours 24 min ago

We must be related!

- The_Ewan 6 hours 54 min ago

But why worry if a few people do? It's just not a big deal....

- Tom_77 7 hours 58 min ago

Tempted to get him a sweary birthday cake like in The Thick Of It....

- Bigtwin 8 hours 26 min ago

Didn't happen did it? They came into my shop a couple of years back and said it was "on the way", but never heard anything more.

Add new comment

6 comments

Beginner??? Where do I start? No mention of tyre levers, or a floor pump, or ordinary simple hand tools like screw drivers and pliers (needle nose and regular). First on the list is a workstand? That's really the first thing I should get? If you're a beginner, do you really need a pedal spanner? A cassette tool and whip? This looks more like "These would be nice to have" tools just kinda dumped out in ramdom order! I am not saying that these are not great tools to have and are even necessary for many jobs, but "Beginner"?

So something like

https://www.decathlon.co.uk/p/900-bike-toolbox/_/R-p-100427?mc=8381080&u...

to get started with? Also need a set of spanners, needle-nose pliers, chain link pliers and a couple of screwdrivers as well.

I love how you talk about quality Hex wrenches and then show a picture of some Draper ones! Wera or Bondhus far better.

I'm just about to upgrade my parks to wera.

Their torxs are superb.

Ordered !

Wera Hex-Plus work very well for me.