- News

- Reviews

- Bikes

- Components

- Bar tape & grips

- Bottom brackets

- Brake & gear cables

- Brake & STI levers

- Brake pads & spares

- Brakes

- Cassettes & freewheels

- Chains

- Chainsets & chainrings

- Derailleurs - front

- Derailleurs - rear

- Forks

- Gear levers & shifters

- Groupsets

- Handlebars & extensions

- Headsets

- Hubs

- Inner tubes

- Pedals

- Quick releases & skewers

- Saddles

- Seatposts

- Stems

- Wheels

- Tyres

- Tubeless valves

- Accessories

- Accessories - misc

- Computer mounts

- Bags

- Bar ends

- Bike bags & cases

- Bottle cages

- Bottles

- Cameras

- Car racks

- Child seats

- Computers

- Glasses

- GPS units

- Helmets

- Lights - front

- Lights - rear

- Lights - sets

- Locks

- Mirrors

- Mudguards

- Racks

- Pumps & CO2 inflators

- Puncture kits

- Reflectives

- Smart watches

- Stands and racks

- Trailers

- Clothing

- Health, fitness and nutrition

- Tools and workshop

- Miscellaneous

- Buyers Guides

- Features

- Forum

- Recommends

- Podcast

TECH NEWS

2021 Enve AG Hannah 2

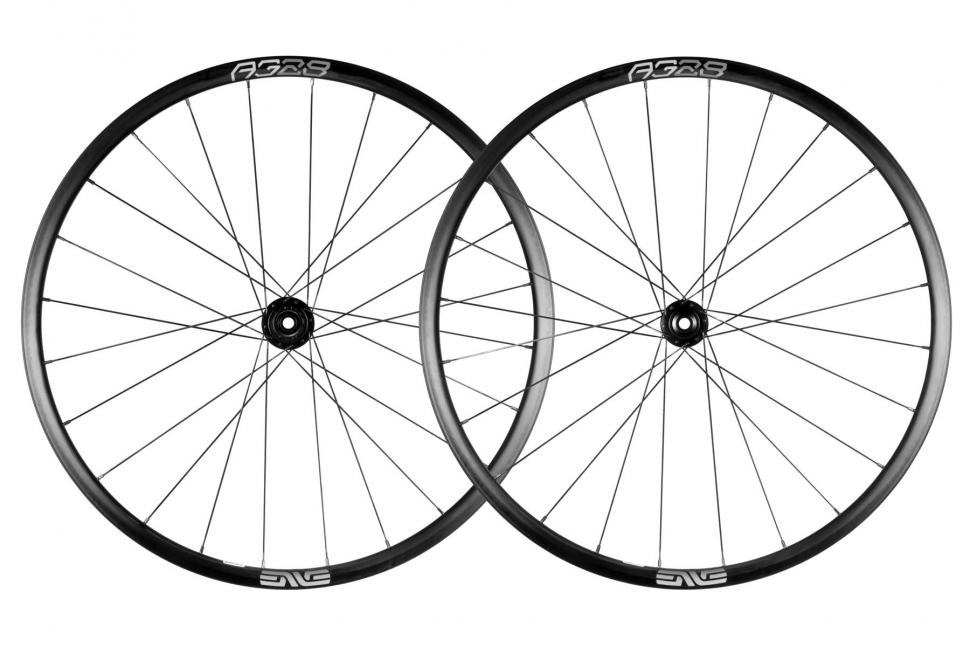

2021 Enve AG Hannah 2Enve expands Foundation collection with AG25 and AG28 carbon gravel wheels

Enve has added to its Foundation collection with the new AG25 and AG28 adventure/ gravel wheelsets which are designed to provide both the durability and performance necessary for everything from racing to bike packing.

Handcrafted in Ogden, Utah, USA, the AG25 is the 700c model and the AG28 is 650b, with the 25 and 28 referring to the inner rim width (mm)—each wheelsets has a rim depth of 21mm.

The AG25 and AG28 form part of the Foundation Collection, which is Enve’s mid-price tier of carbon wheels, featuring the benefits of the brand’s Wide Hookless Bead and Moulded Spoke Hole technologies, but at a lower price, thanks to “simplifying the manufacturing processes [and], reducing labour costs”.

> ENVE launch new Foundation Collection with the all new AM30 wheelset

With weights starting at a claimed 1,460g, these are reasonably lightweight, and the rim design is said to be ready for both race days and the rigours of off-road adventures.

The recommended tyre size is 36mm–50mm for the AG25 (700c), and 47mm–57mm for the AG28 (650b) model.

“With gravel bikes becoming ever-more capable and riders opting for tyre sizes upwards of 50x700c, our engineering team identified rim width increases and strength as key objectives for the AG25 and AG28, while still maintaining a high level of compliance,” Enve says.

As well as increasing rim impact toughness, the wide surface at each of the rim’s leading edges, known as Enve’s Wide Hookless Bead technology, is said to create “a larger surface so that impacts from kerbs, potholes, and debris are distributed over a larger area, reducing the likelihood of pinch-flatting tubes and tubeless tyres”. Enve claims this technology increases protection by over 50 percent compared to a traditional hookless bead, and is patent-pending.

Along with this, to help with choosing the optimal tyre pressure, Enve has a chart with recommendations—based on model and rider weight—which can be found here.

The wheelsets are built for external brass nipples and use the brand’s patented moulded spoke hole technology. Enve explains that because carbon gets its strength from continuous fibres, these fibres in its rims have been routed around the hole, without cutting or drilling, to increase the strength of each spoke hole. Enve says that opting for a conical nipple seat “prevents premature spoke fatigue and failure while also ensuring wheel-build reliability”.

Sapim CX Sprint spokes are laced to Enve’s Foundation Road Hubs which use the same internals as Enve’s premium hubs, but with a simplified shell design and non-stainless-steel bearings.

The rear hub uses an ID360 40t ratchet drive mechanism and what Enve call the Perfect Preload —a maintenance-free automatic system— as found in the brand’s premium hub offerings. This is said to “eliminate the possibility that the hub will develop bearing play and slop over time”.

As with all other Enve products the AG25 and AG28 come with a five year warranty for protection from defects in materials and workmanship, and Lifetime Incident Protection programme for owners' protection from “damage caused to their wheels wile riding, crashing, or transporting their bikes”. Proof of purchase is of course required.

The Enve AG25 and AG28 will retail at a RRP of £1,850 and we aim to get our hands on a set for review.

Anna has been hooked on bikes ever since her youthful beginnings at Hillingdon Cycle Circuit. As an avid road and track racer, she reached the heady heights of a ProCyclingStats profile before leaving for university. Having now completed an MA in Multimedia Journalism, she’s hoping to add some (more successful) results. Although her greatest wish is for the broader acceptance of wearing funky cycling socks over the top of leg warmers.

Latest Comments

- Aluminium can 2 hours 10 min ago

So there's electronics and computers and motors for gear changes and pumping up or deflating tyres. Why not just motorise the whole bike and be...

- ktache 4 hours 6 min ago

Quest are showing the Paris Roubaix highlights at 11 both days.

- chrisonabike 4 hours 51 min ago

Pretty sure a lot of that "more space for motor vehicles" was because fewer motor vehicles (also marginally "smaller motor vehicles")....

- David9694 5 hours 38 min ago

I get the impression he represented himself, came over as a bit of an ass and received a ban, when a lawyer might have got him spared that.

- Rendel Harris 5 hours 41 min ago

Well if you ever get the chance and you feel yourself flagging give me a shout, happy to put in a shift.

- Laz 5 hours 49 min ago

OMG- that's so self centred....what about the brotherhood and sisterhood of enjoying a ride and sharing a happy wave with a fellow rider out...

- thax1 6 hours 16 min ago

Cycliq certainly seemed to let a lot of people down in the early days. I held off until the 12 Sport came out, but have been impressed....

- ktache 6 hours 18 min ago

My better half seems to like giving me pressies of Rapha clothing. I am wearing their casual hoodie right now, and very nice it is too. First off...

- thax1 6 hours 28 min ago

Push on through foot numbness and you then arrive at agonising foot cramp....

- Destroyer666 7 hours 5 min ago

Oh dear, to your own lack of understanding. I was not referring to your vague generalisation of "people", I was referring to a particular...

Add new comment

2 comments

When I see that rim section it always makes me nervous. Hookless. But what about rim blowoffs? There's no such thing as a true standard afaik and the manufacturers of some 'tubeless-ready' tyres, especially the very supple ones such as Compass specifically warn against using any of their products on a hookless rim. Do the benefits to the user of a hookless design really stack up against the risks?

Whatabout rim blow offs? Don't use tyres that are not specified for hookless. This is for running with an appropriate tyre. Blow offs are not prevented by the hook, but by the tension in the bead that holds it tight against the seat on the rim.