- News

- Reviews

- Bikes

- Components

- Bar tape & grips

- Bottom brackets

- Brake & gear cables

- Brake & STI levers

- Brake pads & spares

- Brakes

- Cassettes & freewheels

- Chains

- Chainsets & chainrings

- Derailleurs - front

- Derailleurs - rear

- Forks

- Gear levers & shifters

- Groupsets

- Handlebars & extensions

- Headsets

- Hubs

- Inner tubes

- Pedals

- Quick releases & skewers

- Saddles

- Seatposts

- Stems

- Wheels

- Tyres

- Tubeless valves

- Accessories

- Accessories - misc

- Computer mounts

- Bags

- Bar ends

- Bike bags & cases

- Bottle cages

- Bottles

- Cameras

- Car racks

- Child seats

- Computers

- Glasses

- GPS units

- Helmets

- Lights - front

- Lights - rear

- Lights - sets

- Locks

- Mirrors

- Mudguards

- Racks

- Pumps & CO2 inflators

- Puncture kits

- Reflectives

- Smart watches

- Stands and racks

- Trailers

- Clothing

- Health, fitness and nutrition

- Tools and workshop

- Miscellaneous

- Buyers Guides

- Features

- Forum

- Recommends

- Podcast

TECH NEWS

2020 Met Rivale MIPS helmet - inside.jpg

2020 Met Rivale MIPS helmet - inside.jpgMips says new Finite Element Analysis will “significantly increase safety while reducing the cost to helmet brands”

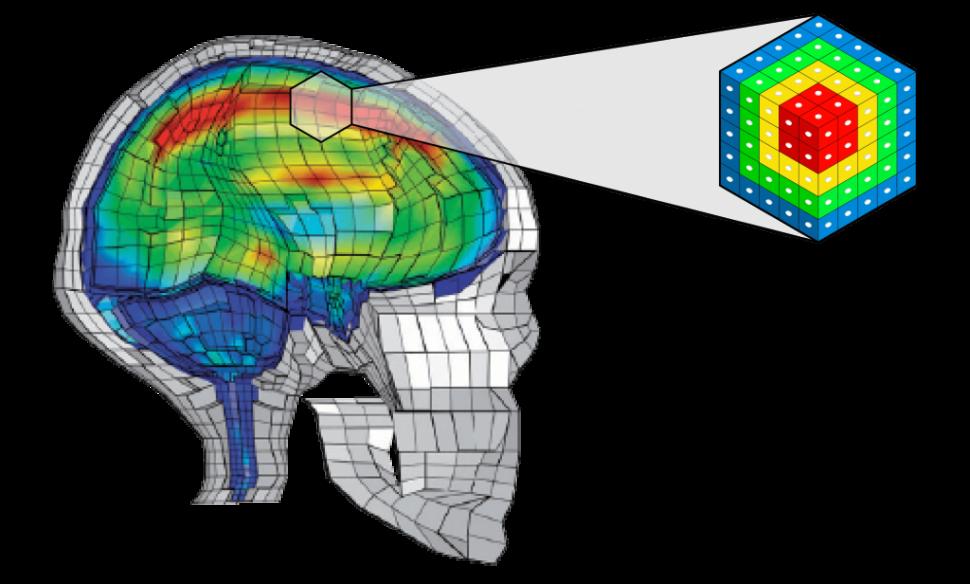

Helmet safety brand Mips has announced new Finite Element Analysis (FEA) that it says could cut the testing phase of helmets by modelling how different designs would perform under rotational impact tests. Mips says that this could also cut costs while also increasing safety.

Developing helmets is, Mips says, a demanding task with many uncertainties. This new tech, it claims, can help helmet brands to cut out some of what is says are lengthy testing procedures as the FEA modelling should help to better predict how a design will perform in the testing phase of development. This, Mips claims, “enables brands to understand earlier in the development cycle how the helmet will perform in both linear and rotational testing.”

Along with faster product development, Mips suggests that fewer iterations of helmets will be needed along with less re-tooling leading to a potential reduction in manufacturing costs which could, in theory, be passed down to customers.

When should you replace your cycling helmet?

MIPS says that it has access to a “state of the art 3D numerical model of the human head, developed by Professor Svein Kleiven at Sweden’s Royal Institute of Technology”

> All you need to know about MIPS

“This computational model represents the most critical parts of the human head, including the skull, brain and other tissues, and relies upon the finite element method (FEM), a numerical method widely used when building houses, bridges or simulating car crashes.

“The model incorporates 50.000 elements connected with nodes (think ‘LEGO’, except in a computer program), allowing us to apply acceleration pulses to the elements representing the skull in the model. The FE software will then compute the strain in each element representing the brain.

> Could Volvo and POC end the helmet debate? Swedish firms partner for "world first" car and cycle helmet crash tests (+ video)

“When applying an acceleration pulse to the head model, the brain will deform in different patterns depending on the impact direction and impact pulse. Our interest is in the strain that has shown to correlate well to the risk of a brain injury, like concussion.”

> Wearing a cycle helmet may increase risk of injury, says new research

“Our 20 plus years of research and simulating real-world accidents has led us to this groundbreaking way to test helmets,” said MIPS CEO, Max Strandwitz. “We are committed to lead the world to safer helmets and at the same time help to improve the development process for helmet brands. This is the way forward, and in a near future we will be able to test all different kinds of helmets according to leading standards, all in the name of consumer safety.”

Latest Comments

- mark1a 1 hour 24 min ago

Still here, just showing a few signs of wear and tear. Hopefully still serviceable for some years to come.

- David9694 1 hour 26 min ago

Oxfordshire village building car crash near Witney...

- Secret_squirrel 1 hour 54 min ago

Has he fully recovered though, and will he ever?...

- Rendel Harris 2 hours 9 min ago

How can you know that you are "equally fearful" as "any female cyclist"? There is no possible way of quantifying such emotions and female cyclists...

- chrisonabike 2 hours 41 min ago

I think it would be fairer to blame the moon - as in "my client is a loony".

- Bungle_52 3 hours 4 min ago

Nice idea but Gloucestershire Constabulary are not interested as exemplified by this prvious NMOTD. Not only was there NFA for the close pass in...

- hawkinspeter 4 hours 36 min ago

I think black boxes are great for early detection of cognitive decline and/or sight problems. Someone's driving is going to become much less smooth...

- Bigtwin 5 hours 11 min ago

It's a fashion. https://guildford-dragon.com/shalford-driver-who-smashed-shalford-war-me...

- MTL Biker 5 hours 32 min ago

Robin Phans .....

Add new comment

6 comments

"Mips says new Finite Element Analysis will “significantly increase safety....."

From less than zero to zero?

All the helmet zealots have been telling us for years that helmets are fantastically effective, so if this is improved, helmets will prevent all injuries and deaths to cyclists, including to arms and legs. Coincidentally, the worst, but still the most quoted helmet research (Thompson, Rivara and Thompson, 1989) found exactly that when the data was analysed by objective researchers; helmets protected arms and legs.

Maybe the helmet manufacturers could explain why their products don't work and how they plan to refund all those people who they have cheated out of their money.

Oh they work! I promise you they work! Having had several helmet-breaking crashes including one major crash caused by a front tyre blowout at 45km/h which snapped my frame, gave me extensive road-rash and caused my helmet to cleave in two, I can assure you they work. I'd rather 'waste' money on a helmet than have a lengthy stay in hospital recovering from extensive head injuries. I'm pretty sure that's what would have happened had I not been wearing a helmet.

It's a common misconception that a damaged helmet has provided significant protection, but it isn't true. There are tens of thousands of these "helmet saved my life" stories, but the death rate of cyclists doesn't fall as helmet wearing rates increase. If your helmet broke in two, it failed catastrophically and absorbed very little energy and provided very little protection. https://www.cyclehelmets.org/1209.html

Let's just wait for the usual abuse from the usual suspect.

So they've created a cae model of the skull and brain and then add the helmet design on top of that and run cycling specific Simulations to see what the G loading is on the brain. I'm surprised people haven't been doing this already to be honest.

That was my thought when reading this. I mean the finite element method is hardly new (really it kicked off in the 60's). I would have hoped that the helmet manufacturers have been doing some basic analysis for years. I am guessing the new part would be modelling the brain as a series of finite elements as they will no doubt have some interesting material properties.

As far as i'm aware, they (and others) have been using FEA for years - it seems like this announcement is about new FEA models and modelling.