- News

- Reviews

- Bikes

- Components

- Bar tape & grips

- Bottom brackets

- Brake & gear cables

- Brake & STI levers

- Brake pads & spares

- Brakes

- Cassettes & freewheels

- Chains

- Chainsets & chainrings

- Derailleurs - front

- Derailleurs - rear

- Forks

- Gear levers & shifters

- Groupsets

- Handlebars & extensions

- Headsets

- Hubs

- Inner tubes

- Pedals

- Quick releases & skewers

- Saddles

- Seatposts

- Stems

- Wheels

- Tyres

- Tubeless valves

- Accessories

- Accessories - misc

- Computer mounts

- Bags

- Bar ends

- Bike bags & cases

- Bottle cages

- Bottles

- Cameras

- Car racks

- Child seats

- Computers

- Glasses

- GPS units

- Helmets

- Lights - front

- Lights - rear

- Lights - sets

- Locks

- Mirrors

- Mudguards

- Racks

- Pumps & CO2 inflators

- Puncture kits

- Reflectives

- Smart watches

- Stands and racks

- Trailers

- Clothing

- Health, fitness and nutrition

- Tools and workshop

- Miscellaneous

- Buyers Guides

- Features

- Forum

- Recommends

- Podcast

feature

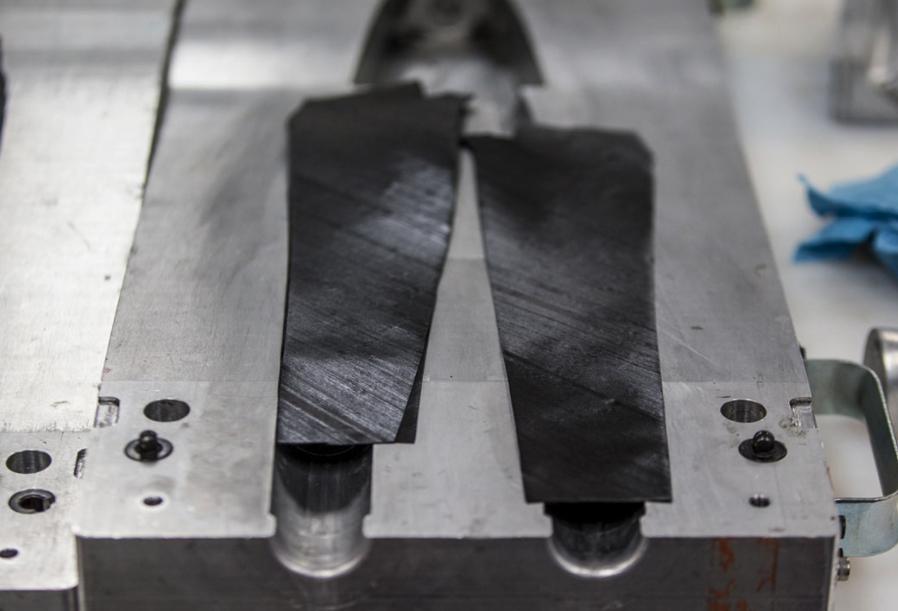

Frame in mould

Frame in mouldWhat is an open mould bike frame?

As the cost of cycling, particularly some of the top road bikes, continues to soar, some consumers are exploring more budget-friendly alternatives, including purchasing open mould bike frames directly from the internet. But what exactly is an open mould bike frame, and should you buy one?

With some of the most recent superbikes costing five figures, many cyclists are looking for cheaper alternatives. As such, open mould bike frames are increasingly prevalent in the cycling industry and appear to be an attractive option, particularly for those on a budget.

How are carbon fibre bike frames made?

In short, making a carbon fibre bike frame starts with a design phase that considers factors like geometry and performance characteristics. In the vast majority of cases, a precisely engineered mould is then created to mirror this frame design.

Carbon fibre sheets and resin are cut into specific shapes and laid up layer by layer into the mould. The orientation and number of layers are carefully planned to achieve the desired strength, stiffness and ride characteristics of that particular frame.

Creating and designing your own moulds is a costly endeavour requiring substantial capacity and resources, making it more feasible for well-established brands with plenty of financial clout. Some brands possess the capability to produce their own moulds internally, while other high-end bike manufacturers will contract factories to create unique moulds exclusive to them.

> Inside Hunt — The secrets behind its award-winning bike wheels

For brands with limited resources and individuals seeking more budget-friendly bike frames, an alternative is to choose a factory in Asia that already has open mould designs available that they can add their branding to.

So, what is an open mould?

You may have heard of the term 'open mould', but what does this mean when referring to carbon bike frames? For those unfamiliar, it is used to describe frames with open-source designs, enabling the use of existing moulds without the need for extensive investment in the mould creation.

A more precise term for this practice would be 'open design', emphasising that the frame shape is not proprietary. Consequently, anyone can use the same mould to manufacture carbon bike frames, resulting in frames with a similar appearance across different brands. The only difference will be the paint scheme and logos.

Companies create open moulds that are available for direct consumer access or through various manufacturers, Planet X and Winspace being such suppliers, meaning they can choose from a selection of designs mass-produced in China rather than designing their own unique frame.

This allows for the production of frames using a variety of materials and making slight modifications without infringing on the rights of the original design.

However, there is a notable difference between purchasing an open mould frame from a reputable UK brand like Planet X and acquiring one directly from platforms like Aliexpress, a retail site that hosts third-party sellers. Buying from a reputable brand ensures some quality assurance and customer support, while obtaining a frame directly from the Far East can be a complex and uncertain experience without the same guarantees.

> Orro on reshoring its assembly, innovation, and plans to go international

Brands such as Specalized, Giant, Cervélo and Orro own their moulds, which is more expensive, but their frames are unique.

For many, the stigma around open mould frames comes from concerns related to quality control, research and development (R&D) and material sourcing. However, it is known that certain 'brand name' companies source carbon fibre from the same providers used by open mould frames, challenging the perception that all open mould frames lack quality or reputable sourcing.

Where is the carbon fibre sourced from?

Toray, headquartered in Japan, is the world's largest manufacturer of carbon fibre, producing material for a variety of industries, including aerospace, automotive, sports equipment, and, of course, cycling.

In the bike industry, most 'brand name' companies source their materials from the same providers as those from open mould factories, highlighting a shared reliance on suppliers like Toray, with brands such as Specialized, Pinarello, Trek, and Giant having used Toray carbon fibre in some of their models.

Carbon fibre is purchased in varying levels and Toray offers different grades of carbon fibre, such as T700, T800, and T1000, with higher numbers indicating higher modulus carbon fibre that is both lighter and stronger.

While the grade of carbon is significant, other factors such as the layup and the type of resin used also play crucial roles in determining the strength and weight of the carbon. As such, not all T700, T800 or T1000 carbon frames are the same.

> Understanding carbon bike frames

> 8 things you didn't know about the new Specialized Tarmac SL8

Resin is mixed with raw carbon fibre before going into the mould, and it's the quality of this resin that impacts the compression strength of the carbon fibre. Cheaper bike frames tend to use cheaper resin, which reduces the strength of the carbon fibre when it's subjected to compressive forces.

When considering a carbon bike frame, knowing the quality of the resin and layup can be challenging for the average consumer. However, opting for well-known bike brands may offer a certain assurance. While the specifics of resin composition and layup may remain undisclosed, reputable brands typically subject their products to more stringent quality control measures, which tend to instil confidence in the frame's construction.

What are the advantages of open mould bike frames?

Despite some scepticism, there are many forum threads online where individuals share their positive experiences with open mould frames, and discuss the merits or pitfalls of buying one.

> How safe is your carbon frame?

One of the primary benefits associated with opting for an open mould frame is its significantly lower cost compared to exclusively designed frames due to reduced expenses needed for research, development and design. By forgoing the expensive process involved in creating proprietary designs, open mould frames offer an affordable alternative for many cyclists.

Furthermore, while open mould designs are accessible to anyone, they still offer room for customisation. The fundamental frame design remains consistent, but manufacturers and individuals have the flexibility to modify specifications, such as bottom bracket configurations, and select different forks and rear triangles to suit their preferences.

> Best Tour de France paint jobs from Specialized, Trek, Cannondale & loads more

Open mould suppliers often provide the flexibility to paint your frame in nearly any colour you want, offering extensive customisation options. Alternatively, you can invest a bit more in custom painting services in the UK once you have the frame, ensuring that an open mould bike can rival brand-exclusive models in terms of a range of design options.

Another notable advantage associated with open mould frames is the accessibility they provide for smaller brands. They make it more feasible for smaller or newer brands to enter the market without the substantial upfront costs of making proprietary moulds, providing a crucial avenue for innovation and competition.

Considerations of open mould frames

Quality assurance poses a significant concern when it comes to open mould frames. While frames acquired from competent factories have the potential to match the strength of those from major brands, the challenge lies in knowing which frames have met rigorous manufacturing standards, and as such, you'll not necessarily know 100% what you're getting.

While certain factories and brands may prioritise stringent quality control measures and have the capacity to produce high-quality frames, the concern arises from the potential variation in manufacturing standards amongst different companies. As a result, careful consideration is crucial when choosing open mould frames.

Established brands often offer longer warranties compared to open mould frames and tend to provide better customer support. Leading brands such as Specialized, Trek and Giant have more at stake in case of any issues, often meaning the customer has an advantage when it comes to warranty claims or necessary repairs.

Also, when purchasing a frame from an open mould brand in the Far East, you often engage in a faceless transaction. If something goes wrong, resolving the issue might not be as simple. Not knowing if you'll ever see the fruits of your funds adds an extra layer of uncertainty to the entire experience.

> Cycling and sustainability: What you can do to further reduce your carbon footprint

Resale value may also be a consideration if you plan to upgrade or sell the bike in the future. Brand-exclusive models from reputable manufacturers often retain better resale value compared to generic designs.

It is also argued that open mould frames lack uniqueness and a brand identity, but some people would argue that there's no reason to invest in a frame that costs a lot more solely for the prestige associated with the brand name.

So, what should you do?

The decision to choose between a cheaper, generic design and a more expensive brand-exclusive model depends on several factors and individual preferences. However, a practical consideration that many individuals face is the increasing prices of well-known brands, leading them to explore alternative options that strike a balance between affordability and quality.

The bike's primary purpose and the choice of vendor are also crucial considerations. I've been using a Dream track bike - an open mould frame - for nearly a decade without any issues. However, I strongly recommend purchasing from a reputable vendor due to their commitment to higher quality standards.

It's worth noting that less reputable vendors, while claiming to be manufacturers, often source frames from other factories, essentially operating as middlemen. This reduces the likelihood of receiving a response in the event of any issues or concerns. Be sure to research reviews and recommendations from other cyclists for a more informed decision.

It's also worth checking the import taxes for your country, as an open mould frame may incur additional costs that will drive up the overall amout you spend.

> Which Tour de France superbike is the best?

It's recommended to visit local bike shops, test-ride different models, and gather as much information as possible before making a decision. If you want a new bike but don't want to pay loads, it's also worth considering second hand bikes. You can get a very good quality bike for a fraction of the original cost.

What are your thoughts on open mould bike frames? Let us know in the comments section below...

Emily is our track and road racing specialist, having represented Great Britain at the World and European Track Championships. With a National Title up her sleeve, Emily has just completed her Master’s in Sports Psychology at Loughborough University where she raced for Elite Development Team, Loughborough Lightning.

Emily is our go-to for all things training and when not riding or racing bikes, you can find her online shopping or booking flights…the rest of the office is now considering painting their nails to see if that’s the secret to going fast…

Latest Comments

- Pub bike 1 hour 7 min ago

The highway code doesn't say "If you are approaching a cyclist from behind sound your horn"....

- Disgusted of Tunbridge Wells 3 hours 34 min ago

Erm... You forgot to mention The Tyne Tunnel opened in 1951!!!...

- Destroyer666 4 hours 6 min ago

Always? So the guy is asked to appear on a podcast to discuss performance enhancing drugs and answers questions posed to him, which go beyond what...

- David9694 4 hours 25 min ago

"Babergh District Council said it had been "clear throughout" that it "had no option but to introduce charges" and could not afford to continue to...

- Pub bike 5 hours 2 min ago

Maybe it is the latest ruse for insurers to avoid payouts saying "You didn't tell us that you took the key out of the lock so we're refusing your...

- KDee 8 hours 21 min ago

I'm still running an ELMNT BOLT V1, and I've never really understood the LED's. I'm sure I configured them for HR zones, but never really look at...

- don simon fbpe 9 hours 46 min ago

Why is this not the will of god?

- hawkinspeter 12 hours 50 min ago

PKD foresaw it, though his novel was based on a different outcome of WWII, not the precursor to WWIII. Maybe the Idiocracy film is a closer fit?

- OnYerBike 14 hours 52 min ago

@Sredlums: I'm not sure I follow your logic. If someone grabs your helmet twists it, then the reason it doesn't feel good is because the outer is...

- Rapha Nadal 14 hours 52 min ago

Coming to the mid-paced Saturday club ride soon.

Add new comment

11 comments

As ever, researching before purchasing is important. There are numerous forums and sites where you can go to read experiences of ordering from China (whether through an agent or direct), and where people compare to established brands selling their own versions of the same frame. For example I bought a frame from Carbonda, which is a small company which acts as an agent to buying from one of the huge frame makers, I can't remember which now. It was specifically recommended online by plenty of people who had ordered and had no problems. The riskiest thing is going onto AliExpress and picking a seller at random. You'll probably get something ok, but you might get a rejected/repaired frame, or one by a smaller company employing people with no real experience or QC.

I think I recall hearing Peak Torque on YouTube saying he'd bought many things direct from China/ Far East with good results. I doubt if I'd have the nerve and I'm not interested in carbon frames or wheels anyway.

they also make excellent steel and titanium frames

There is certainly a lot more content to fully understand how Carbon Fibre frames and forks are manufactured, different types of Carbon fibres, resins, layups etc. I think Emily has done a good job to scatch the surface here.

The opportunity for any cycling fan to purchase an 'Open Mould' or 'Catalogue' frame from Asia is pretty straight forward. The purchasing decision is down to the individual. Normally price driven. If you are prepared to make that purchasing decision, it can be bit of a gamble. If you are willing to take that gamble, why not ?

From my experience, I know how much investment in money and hours it took to develop our frame and forks, seat posts, bar stem combos etc. including meeting ISO safety standards, then setting and maintaining our QC standards.

As Emily has mentioned, there are a number of brands in the UK who have selected a carbon frame from a suppliers open catalogue, yet claim its their own design.

Every cycling fan has the opportunity to make their purchasing decision to what suits them best. I dont think anybody can argue with that ?

I think you will find that most, if not all, frame manufacturers are ISO rated and maintain EU QC standards - otherwise they could not sell them

"buy from reputable brands like planet-x" haha, nice one. Anyway, I've bought three frames direct from Chinese suppliers plus some carbon rims and bars. All the transactions were satisfactory and I've had great service from my items.

Motivation is mainly financial. Speckilizd knocks out 10s of thousands of Sworks frames and still asks £4k a pop. Sorry, just No. The most recent frame I bought, an all-road design I must have 10,000km on by now, cost me £675 delivered including an integrated bar. And I got to choose a nice paint colour.

I'm aware of the risks and sanguine about them and I'm well able to deal with most technical issues. Not everyone will feel the same. In return I don't break the bank, I get a bike I don't need to be precious about, and in a way it's more personalised than any off the shelf 10k superbike.

"Toray offers different grades of carbon, such as T700, T800, and T1000, with higher numbers indicating higher quality carbon that is both lighter and stronger."

Err, no. Firstly carbon is an element so there's no higher quality carbon available. Secondly the Toray number indicates characteristics in the material, sheets with a higher number will exhibit an increase in tensile strength at the cost of flexibility. A well engineered frame will utilise various grades in places where flexibility or tensile strength is prioritised

Well, there's different isotopes. I always insist on using Carbon 8 as that's the lightest, though it doesn't seem to last as long.

The lightness (and fragility) of carbon8 is down to the bubbles, like RAAC.

I like frames made of Carbon 14, I've got one that still going strong after 5730 years and amazingly it's only half the weight it was originally.

Does it harvest the N14 to keep the tyres topped up?