- News

- Reviews

- Bikes

- Components

- Bar tape & grips

- Bottom brackets

- Brake & gear cables

- Brake & STI levers

- Brake pads & spares

- Brakes

- Cassettes & freewheels

- Chains

- Chainsets & chainrings

- Derailleurs - front

- Derailleurs - rear

- Forks

- Gear levers & shifters

- Groupsets

- Handlebars & extensions

- Headsets

- Hubs

- Inner tubes

- Pedals

- Quick releases & skewers

- Saddles

- Seatposts

- Stems

- Wheels

- Tyres

- Tubeless valves

- Accessories

- Accessories - misc

- Computer mounts

- Bags

- Bar ends

- Bike bags & cases

- Bottle cages

- Bottles

- Cameras

- Car racks

- Child seats

- Computers

- Glasses

- GPS units

- Helmets

- Lights - front

- Lights - rear

- Lights - sets

- Locks

- Mirrors

- Mudguards

- Racks

- Pumps & CO2 inflators

- Puncture kits

- Reflectives

- Smart watches

- Stands and racks

- Trailers

- Clothing

- Health, fitness and nutrition

- Tools and workshop

- Miscellaneous

- Buyers Guides

- Features

- Forum

- Recommends

- Podcast

TECH NEWS

Colnago Y1Rs

Colnago Y1RsThe bike Pogačar wins Milan-San Remo on? Colnago claims outlandish new aero road bike is "most aerodynamic in the WorldTour"

The leaks were right, Colnago has a new aero road bike for 2025, the Y1Rs apparently the "most aerodynamic road bike in the WorldTour" and designed specifically for UAE Team Emirates and Tadej Pogačar.

Colnago claims the Y1Rs is "faster than the current fastest competitor" in testing and saves 20 watts on its V4Rs model at 50km/h. Unsurprisingly, given its aero focus, the Y1Rs frameset is 242g heavier than the V4Rs and it will cost €6,710 (£5,560) or €16,200/£13,430 in the build to be used by Pogačar and UAE teammates, with Shimano Dura-Ace Di2 and Enve SES 4.5 wheels.

The Italian bike brand is keen to point out its "state of the art approach to aerodynamic studies", Colnago also suggesting it created an aerodynamic testing model "that is twice more accurate than the industry standard" CFD modelling, informing the claim the Y1Rs is "faster than the fastest competitor" and outperformed "the top aerodynamic road bicycle now on the market" in any wind conditions.

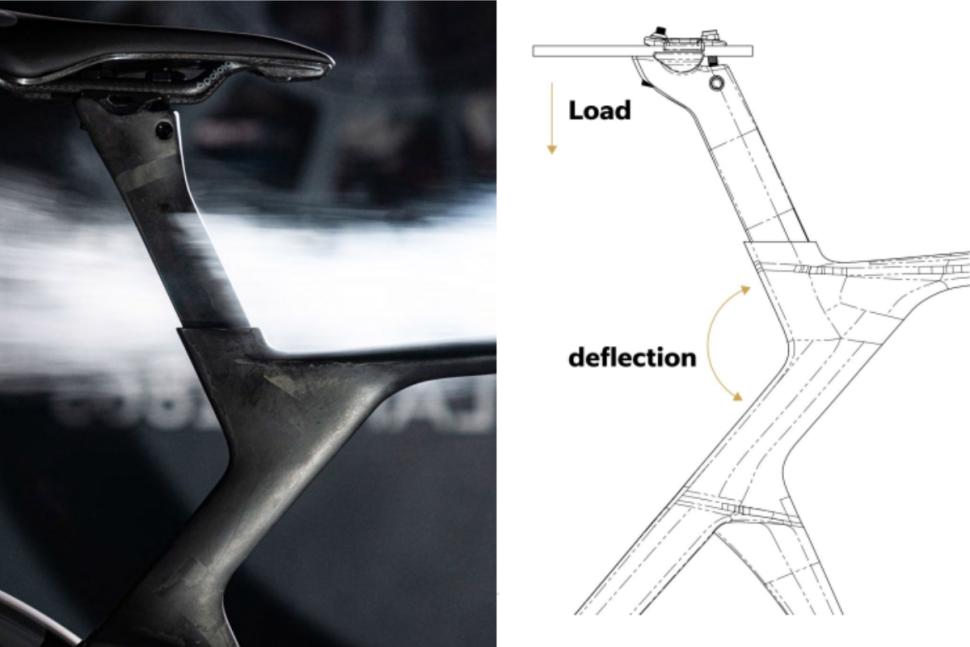

Among a host of design features aimed at aero optimisation, attention is immediately drawn to that striking seatpost joint, officially named here as the 'DEFY shape' by Colnago, which sent the cycling world into something of a spin when leaked images of the new model appeared online last week. The bike manufacturer suggests the joint uses two linked 'y' shapes, one of which is upside down, resulting in claimed increased vertical compliance and comfort by "increasing the angle of the seatpost".

Colnago also suggests the shape, enabled by new UCI standards, means the seat tube can "follow the shape of the rear wheel and thus be aerodynamically more effective in an area where the cyclist's turbulent pedalling flows arrive". The seatpost has to be cut to be positioned and once inserted there is space for further adjustment of "about 1.5cm".

The cockpit is new too, the CC.Y1 'WYND' shape integrated handlebar also apparently "proven to be the most aerodynamically efficient solution". The 'gull wing' structure sees the horizontal part raised and detached from the central part of the headset, in a way not dissimilar to the shape and elevation Cervélo's V-stem design.

Colnago says it aims to allow a "significant reduction in the frontal area and faster and cleaner airflows on the main body of the bike". The Y-shaped front end is said to reduce the frontal area by 19 per cent compared with the V4Rs, the CC.Y1 prioritising "extreme aerodynamics and stiffness", while the CC.01 of the V4Rs is "still the best compromise in terms of weight-savings and aerodynamics".

The bars are Colnago's "stiffest in testing" and "16 per cent stiffer" than an unnamed reference competitor in vertical and lateral stiffness.

Elsewhere on the design front is the revised headset to "take advantage of new UCI rules" to "improve speed of lateral air flows", while the manufacturer also suggests the smaller headset bearings and internal/external parts to the fork "improve how air impacts the frontal area of the bicycle". In short, it's all more aero, you won't be surprised to hear. That's also the story with the "optimal shape of the downtube" and integrated bottle cages.

The Y1Rs was publicly unveiled at the UAE Team Emirates and UAE Team ADQ training camp in Benidorm and has been designed to meet their professional riders' needs.

Colnago explains how the teams like using the V4Rs as an "all-rounder" but that "for specific races we need a focused aero bike". Will the Y1Rs finally be the model that Pogačar rides to that so far elusive Milan-San Remo victory next season?

With races getting faster, climbing speeds now often above 20km/h (thanks, Tadej), long-distance attacks becoming the norm (thanks, Tadej), and more time trials with mixed profiles of climbing and flat — the manufacturer highlighted the need to produce the most aerodynamically efficient model possible.

Colnago reckons the Y1Rs is, according to its studies, the "most aerodynamic UCI-compliant road bike in the WorldTour", the new model apparently outperforming "the top aerodynamic road bicycle now on the market in any wind conditions", findings which the brand says were replicated during a "complete race set-up" test where a dressed mannequin was added to simulate a pro rider in a race.

It is also "significantly better than the current fastest competitor with real life lateral wind conditions" too, and compared with the V4Rs, the Y1Rs saves a reported 20w at 50km/h.

"A model that is twice more accurate than the industry standard"

Colnago hasn't just made claims about how its bike tested, but also about how the entire bike industry does testing.

Calling CFD models (which simulate airflow around a bike and drag force of different design solutions) a "simplified description of real aerodynamic flow", Colnago says it created a "more descriptive" testing model which is "twice more accurate" than CFD.

"We drilled some bikes with 70 holes to measure the pressure on each section of the tube," Colnago explained. "We then fine tuned our model and modified again the shapes of the original bike and tested it again.

"Thanks to 3D printing technology, we created several samples of different prototypes of the Y1Rs. Those samples replicated exactly the shapes and surfaces of the carbon prototype. We then mapped the surface of the bike, drilling some very small holes on the frame at regular distance one from the other. Each hole was connected, through a thin tube, to a special machinery that was able to measure the pressure of the air on the surface of the bike, in the point where the little hole is located.

"With this information we were able to measure with a high degree of precision the pressure (and the variation of pressure) on every single bit of the bicycle. We then compared this information with our CFD models and refined them further."

So, there, Colnago tells us it has created a new, more accurate way to test bikes' aerodynamics and that, as per its method, the Y1Rs is the most aero bike out there.

Moving on. No bike launch would be complete without weight and stiffness claims, would it? Unsurprisingly, given the Y1Rs' aero aims and the V4Rs' climbing qualities, the new model is 242g heavier, and stiffer.

"While V4Rs is an all-rounder focused on Grand Tour, Y1Rs — having less weight constraints — has been tuned for improved stiffness in sprint positions," Colnago also said, claiming its in-house testing system puts the exact figure of improved stiffness at 3.5 per cent when sprinting.

Compared with the V4Rs, the main geometry differences are the slightly steeper head tube and seat tube angles, naturally giving riders a more forward-oriented tuck position to optimise aerodynamics. The Y1Rs also has an increased reach/stack ratio to also accommodate more aggressive, extended positions.

The model starts at €6,710 (£5,560) for the frameset, and €12,300 (£10,200) with SRAM Red and Vision's Carbon 45 wheels. Equipped with Shimano Dura-Ace Di2, the Y1Rs starts at €13,200 (£10,945), also with the Vision Carbon 45 wheels.

Colnago is also offering Dura-Ace Di2 builds with Shimano C50 wheels (€15,000/£12,435) or Enve's SES 4.5 wheelset (€16,200/£13,430), that last option the likely set-up we'll see Pogačar and Co. riding next season.

The most expensive build offered is for the Y1Rs with Campagnolo Super Record Wireless and Bora Ultra WTO wheels. That option is priced at €16,500 (£13,675). The full information and spec options can be viewed on Colnago's website.

It is the brand's second major launch in recent weeks, following on from the new steel road bike "masterpiece" — the Steelnovo — which costs £14,500 and uses only Italian-made components.

We spoke to Filippo Galli, the lead engineer on the Y1Rs, for an insight into what went into the design and how Colnago expects it to be used next season…

road.cc: Could you explain the overall objective of the Y1Rs project, and when it began, please?

Filippo Galli: The idea for the Y1Rs started with the change in UCI regulations that began in 2022 and became effective in 2023. These changes to the regulations allowed us to conceive a bicycle which has an advantage in terms of aerodynamics without compromising the overall performance. These results are mainly due to two aspects: first, the change of the allowed tube ratio from the old 3:1 to 8:1, and second, the possibility to move the seatpost position, as long as it is in contact with the top tube.

Colnago saw the possibility of developing a fully aero bike, which does not compromise other aspects of the performance. This bicycle is not replacing our V4Rs, the all-rounder which will remain the main choice of the team in some situations, for some stages. This bicycle is not replacing the V4Rs, it is another bike aside the all-rounder.

In terms of aerodynamics and the design process, it sounds like Colnago was pretty dissatisfied with the accuracy of existing CFD (computational fluid dynamics) software. Could you tell us how come, and what you were able to do about that?

The point here is that everyone developing an aero bike uses CFD. However, since our first tests in the wind tunnel, we measured a difference of about 30 per cent [between CFD results and wind tunnel results]. Thanks to the universities we are collaborating with – Politecnico di Milano and Khalifa University – we found that in common approaches, there is this delta of about 30 per cent with respect to experimental data.

What we did, from the early stages of the development, is perform some experimental tests with some 3D-printed bicycle changeable parts fitted with some pressure pressure sensors in relevant areas. I'm referring to the frontal area – the handlebar, fork, headset head tube, down tube – equipped with pressure gauges to measure totally what is happening to the airflow. This allowed us to see what was happening at the level on the bicycle, and we could input this data to the CFD model to tune all the parameters that are required by a CFD model to achieve better precision.

We were able to achieve a much better precision: from 30 per cent of the initial state of the art, down to 15 per cent difference, which gives much more reliability in comparing different designs solution.

This process does not end with this bicycle. The collaboration with the universities is still open. We are still working in order to be able to simulate even better what is happening.

You mentioned the two universities; at what stage did you involve them?

From the really early stages, just after we had a rough idea of what we would like to do so. After the conceptual design, just with the shape or a very rough design, we started collaborating with the universities and in order to model the bicycle considering the optimisation of tube shapes.

Different bicycles with different design parameters, different shapes at a different wind conditions and different speeds, different angles… The amount of data is huge, and the collaboration lasts from the beginning to this final stage.

You've managed to reduce the frontal area of the bike – the head tube, in particular, by 19% compared to the V4Rs. How was this achieved?

The tube shape is very thin, and so the overall front area is reduced. The other big improvement came from the handlebar. The Y-shaped handlebar, coupled with a very low swooping top tube, allowed us to reduce the airflow in the central part of the handlebar, where usually there is either the stem or the integrated stem, which disturbs the wind flow. The handlebar will be provided in five different stem lengths and two different widths.

Last but not least, the overall head tube, which is designed with a bayonet fork, has a very thin profile. That is important to the design without compromising the overall stiffness of the system.

Colnago says, “We're confident that this solution is the final world word on the optimal down tube configuration within the limits of the current UCI regulations.” How come?

The position of the down tube is still an area of debate in the bicycle business. Some brands have the down tube very far from the wheel, and others keep the down tube as close as possible to the front wheel.

We tested both of the solutions in the wind tunnel, and we simulated both. We have prototypes. We measured the wind flow on the down tube thanks to the pressure gauges positioned in the different sections. We end up with this final solution; a down tube which is as close as possible to the front wheel within the regulations of the UCI and considering the tyre clearances needed for the intended use of this bicycle.

We have a down tube which is as close as possible to the wheel which, coupled with the optimised foil shape, provided the best results of all the tests we did

The seat post is separated from lower section of the seat tube; could you explain the importance of that aspect of the design?

This is one of the most characteristic features of this bicycle. The idea to move the seatpost and to decouple it from what is still called the seat tube (but you can see that the name ‘seat tube’ is quite strange for this kind of bike), is mainly due to two reasons. The first one is vertical compliance, and the second one is aerodynamics.

In terms of aerodynamics, in this area, where the flow is already disturbed by the presence of the legs and the cyclist, the less material you have to disturb the flow means less drag. Moving everything forward to avoid any interaction with the airflow – this means less drag at the end.

Regarding vertical compliance, this is very interesting part, because it's really connected with our proposed design for this bicycle. Our proposal was to design a fully aerodynamic bicycle, but that still be ridden without compromising the riding quality. This was a strict request from Team UAE. They required a super-aerodynamic bicycle, as long as the weight is competitive and the ride-feeling wasn’t compromised.

Positioning the seatpost in a forward position and slackening the seat tube angle quite a lot – we are talking about 65° – allows vertical compliance while retaining the maximum stifness required by the sprinters.

Adding this feature – with additional vertical compliance – helps keep the bicycle comfortable for the longer stages, especially if you are riding in super-attack position. Being able to stay in the attack position in a more comfortable way… The rider is still the biggest element in the aerodynamics, so helping them keep the most aerodynamic position is for sure a benefit.

Colnago says that a rider on the Y1Rs requires less power to go the same speed as a rider on the V4Rs. Can you tell us how they compare?

To answer this question, it’s interesting to understand the approach of the team. The two bicycles [the existing V4Rs and the Y1Rs] are available to them. The team is now comparing the two bicycles in different conditions and in different setups. They are testing the bicycles with different wheels, with different tyres, in order to collect data and understand which bicycle and setup performs best in different conditions.

For sure, the Y1Rs is the bicycle for flat stages when riders are in the wind at the front of the peloton, in the breakaway for a long time. This bicycle performs better since aerodynamics is more relevant at high speed. In this situation, the Y1Rs performs better than the V4Rs.

For climbing in the pure mountain stages, the V4Rs is still the choice of the team.

In a nutshell, I can see that this bicycle will be used for the fast stages, for the sprinters, of course, and in stages where the riders will stay in the wind at the front of the peloton.

I expect some riders to stay on this bicycle most of the season. Some other riders – especially smaller riders who are pushing on the last climb of the stage – will use the V4Rs. Other riders – the majority – will switch from the Y1Rs to the V4Rs according to the different the stages.

Let’s quickly talk about the fit...

Since you don’t have the traditional reference points on the Y1Rs, because the seat angle changes according to the saddle height [unlike most bikes, the seatpost isn’t at the same angle as the lower part of the seat tube] and you don't have any reference in the middle of the handlebar.

On this topic, Colnago is providing a tool on the website that allows the final user to keep some reference points. By using these reference points, the tool is able to provide recommendations in term of frame size, in terms of seat post (we have two different seatposts, one with zero offset, one with 15mm of setback), in terms of cockpit size and also the number of spaces that can be placed below the stem.

And going forward…

This is for sure one of the longest Colnago projects. Colnago is really proud both of the results of the Y1Rs itself and of the very scientific approach that we implemented for the development of this bicycle. That will remain for the future, for whatever new performance bicycle we are going to design.

Dan is the road.cc news editor and joined in 2020 having previously written about nearly every other sport under the sun for the Express, and the weird and wonderful world of non-league football for The Non-League Paper. Dan has been at road.cc for four years and mainly writes news and tech articles as well as the occasional feature. He has hopefully kept you entertained on the live blog too.

Never fast enough to take things on the bike too seriously, when he's not working you'll find him exploring the south of England by two wheels at a leisurely weekend pace, or enjoying his favourite Scottish roads when visiting family. Sometimes he'll even load up the bags and ride up the whole way, he's a bit strange like that.

Latest Comments

- chrisonabike 1 hour 1 min ago

Agreed - if you've had the bike a while you've probably added bits to it / upgraded. In my case that included about 150 quid of cut locks......

- chrisonabike 1 hour 8 min ago

Hmm... I'm sure "more could be done" but there are two parties here. It seems hard to reach people with "council information". Particularly with ...

- mdavidford 1 hour 33 min ago

"Driver fined £100 after stopping to be sick" https://www.bbc.co.uk/news/articles/ce8g13pp0plo

- ktache 1 hour 56 min ago

Not that they would be as technical, or maybe quite as grippy, but does the skate industry provide any solutions?

- wtjs 2 hours 12 min ago

the Metropolitan Police contacted Vikash to inform him that they have created a report for the incident and that the video has been “passed to the...

- Rendel Harris 2 hours 39 min ago

Sorry to be a killjoy but it doesn't amuse me at all, I hope the idiot gets caught and punished. Putting yourself on the same road as pros...

- willpom @GWRaudax 3 hours 14 min ago

Steve Poulton has just published The Cheltenham Flyer - 10th May https://www.audax.uk/event-details/calendar/13235-cheltenham_new_flyer_200

- David9694 3 hours 31 min ago

Chef left with 'car sticking out of house' on crash-hit road...

- HKR 6 hours 25 min ago

It's not 4k though. It's a 4k sensor. But when image stabilization is on, that's chopped down to little over a 1080 image. ...

Add new comment

4 comments

Not a fan of the paint job but I think it looks pretty cool.

At any rate, it will piss a lot of people off which is great becuase cyclists are an easy bunch to wind up.

"Bikes today all look the same, back in my day..."

"Euuuugh, that bike that looks different is so ugly, why would anyone want that"

Like Pogacar needs an aero advantage. He literally could win anything on 2 wheels, the rest of us can splash out £15k and pretend.

Well, Colnago needed something new to perserve their rightful cut of the money that a subsection of the dentist community has been making fixing the smiles of rich kids.

"....you ain't got no alibi!", as the song says.