- News

- Reviews

- Bikes

- Components

- Bar tape & grips

- Bottom brackets

- Brake & gear cables

- Brake & STI levers

- Brake pads & spares

- Brakes

- Cassettes & freewheels

- Chains

- Chainsets & chainrings

- Derailleurs - front

- Derailleurs - rear

- Forks

- Gear levers & shifters

- Groupsets

- Handlebars & extensions

- Headsets

- Hubs

- Inner tubes

- Pedals

- Quick releases & skewers

- Saddles

- Seatposts

- Stems

- Wheels

- Tyres

- Tubeless valves

- Accessories

- Accessories - misc

- Computer mounts

- Bags

- Bar ends

- Bike bags & cases

- Bottle cages

- Bottles

- Cameras

- Car racks

- Child seats

- Computers

- Glasses

- GPS units

- Helmets

- Lights - front

- Lights - rear

- Lights - sets

- Locks

- Mirrors

- Mudguards

- Racks

- Pumps & CO2 inflators

- Puncture kits

- Reflectives

- Smart watches

- Stands and racks

- Trailers

- Clothing

- Health, fitness and nutrition

- Tools and workshop

- Miscellaneous

- Buyers Guides

- Features

- Forum

- Recommends

- Podcast

TECH NEWS

2022 Verve Cycling InfoCrank 3D Ti 2

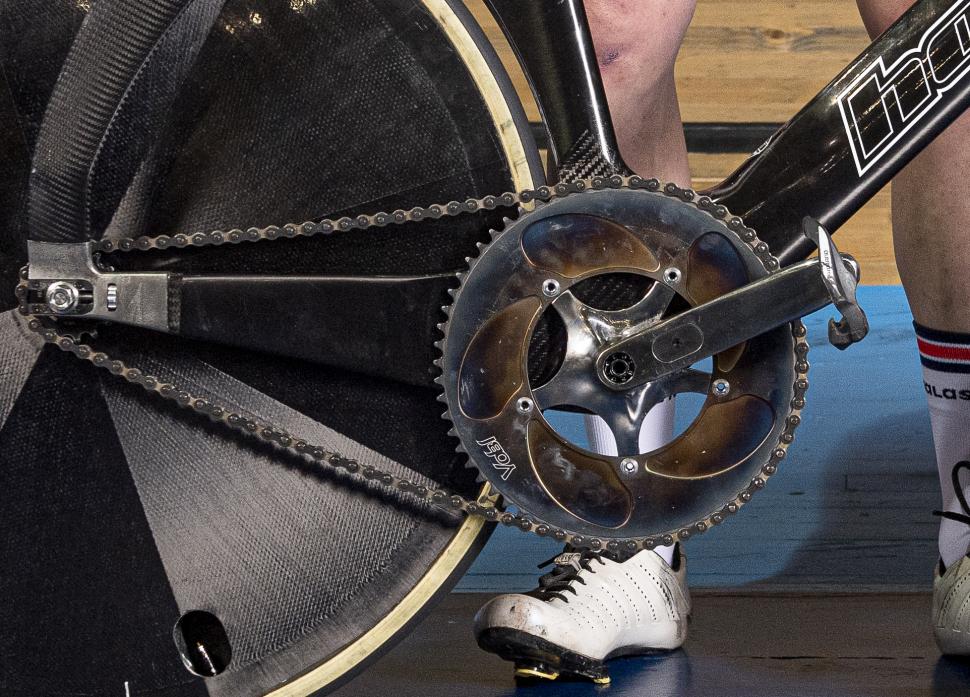

2022 Verve Cycling InfoCrank 3D Ti 2Verve unveils £4,740 3D-printed titanium crankset power meter with 'unparalleled accuracy'

Verve Cycling has developed a 3D-printed titanium crankset that offers dual-sided power meter measurement with an error of less than 1% claimed, along with no recalibration or regular re-zeroing required. It claims to be the first power meter to combine “true torque based power measurement with a 3D printed titanium crank arm”... but priced at £4,740, as far as we’re aware this makes it the most expensive power meter on the market.

The new InfoCrank 3D Ti - that’s been designed in-conjunction with Metron Addictive Manufacturing - is claimed to measure rider torque and cadence from within the crank arms to calculate power output with “a degree of accuracy totally unparalleled within the industry”.

> The 10 best cycling power meters: which one is right for you?

Verve Cycling joined forces with 3D titanium printing and composites expert Dimitris Katsanis in 2021 to 3D print the cranks in order to produce what it’s calling a “game-changing power meter”.

Katsanis founded Metron Additive Engineering, and is truly an industry veteran. He has been the principal design consultant for Team Sky/Ineos, and is famous for designing the British Cycling track team bikes which were piloted by multiple medal winners at the Beijing 2008 and London 2012 Olympics.

“Traditionally in manufacturing you can only design for areas that you can access – essentially the outside,” Verve Cycling points out.

“However for cranks the ideal shape is a closed box with some internal structures and varying wall thickness. This is very difficult to achieve with traditional manufacturing as you generally can’t get to the inside faces. 3D printing means you can design exactly what you need.”

As a result, Verve Cycling says it has been able to produce a crankset that directly measures rider torque and cadence from within the crank arms, at a rate of 256 times per second per crank arm, to calculate a cyclist’s power output. It says other power meters measure multiple forces and use mathematical algorithms to estimate power output.

“The crank arm design and strain gauge placement fully isolate the tangential force, which is the only force propelling you forward, and so as with its predecessor the InfoCrank Road there's no need for ongoing recalibration, zeroing, and all the other tricks designed to average out the unavoidable inaccuracy that comes from not directly measuring,” Verve Cycling explains.

As it's 3D-printed in titanium, “world-beating strength” in a lightweight package is also promised.

“Ti6Al4V titanium is melted by a high power electron beam under high vacuum conditions, at a facility that is aerospace qualified (AS9100 Rev D) - about as high tech as it can be in terms of manufacturing,” Katsanis says.

The track version of the new crank is already being use by the Great Britain Cycling Team, while the road version is expected to be available this spring.

The road variant will have a proprietary 24mm bottom bracket axle that fits straight into the rider’s choice of bottom bracket. With a wide range of lengths available and four-arm and five-arm spiders, Verve Cycling says the power meter can be adapted to any set-up.

The InfoCrank 3D Ti works identically to other InfoCrank power meters, and connects via ANT+ to all common head units.

The road model is being sold for a mega pricey £4,740 - to put that into perspective, the most expensive model we rate is Shimano's Dura-Ace FC-R9200-P which costs £1,200. Verve Cycling says prices for customised versions are provided on request, and the brand adds that it is currently working with five national governing bodies as well as the UCI currently on special projects.

Anna has been hooked on bikes ever since her youthful beginnings at Hillingdon Cycle Circuit. As an avid road and track racer, she reached the heady heights of a ProCyclingStats profile before leaving for university. Having now completed an MA in Multimedia Journalism, she’s hoping to add some (more successful) results. Although her greatest wish is for the broader acceptance of wearing funky cycling socks over the top of leg warmers.

Latest Comments

- Rendel Harris 1 sec ago

Not every freehub makes a noise, especially older ones manufactured before sounding like a Maxim gun apparently became a badge of honour.

- ubercurmudgeon 30 min 38 sec ago

Some quotes need to be put around the word "reciprocal" in the first paragraph.

- David9694 1 hour 6 min ago

this one is wide open for puns, come on people.

- BikingBud 1 hour 7 min ago

Do you mean this woman, who got out to marshall the truck through and is now walking back to said Wankpanzer which is blocking the road again as it...

- mark1a 1 hour 22 min ago

This simply isn't true. I've been running radar lights for 10 years now. I cycle mostly on rural roads, I get notified of approaching vehicles up...

- Rendel Harris 3 hours 52 min ago

Genuinely puzzled as to how you've extrapolated that from what I said. Care to explain?

- Pub bike 6 hours 2 min ago

He is up against the global trading system, which has obviously been in the news a lot lately. Framebuilders in other countries can undercut him,...

- Destroyer666 19 hours 26 min ago

Have you owned Bont shoes? In my experience even the widest Lake shoes have had a bizarre form of narrowing way too much in the toe area. But the...

Add new comment

3 comments

For an idea of how accurate a well-designed torque meter could be, the ones I buy for work (I'm a measurement engineer for engine testing) are ±0.02% or ±0.04% of reading over a wide range. Way better than needed for cycling performance, and actually better than I need. I'd be happy with ±0.25%, but the cheaper ones are not as reliable, and that's more important to me.

Hmm. Would like to see stiffness data on that design. It looks like they've had to compromise: the sides of the crank arm are parallel and relatively narrow, which is needed in order to get a uniform strain for the strain gauges, but will not be optimal for stiffness.

Not 100% correct, the area around the strain gauges is ideally uniform, the rest can be whatever it wants. And because its additive they can change the wall thickness internally to increase stiffness while keeping a profile that is desired for aesthetics.