- News

- Reviews

- Bikes

- Components

- Bar tape & grips

- Bottom brackets

- Brake & gear cables

- Brake & STI levers

- Brake pads & spares

- Brakes

- Cassettes & freewheels

- Chains

- Chainsets & chainrings

- Derailleurs - front

- Derailleurs - rear

- Forks

- Gear levers & shifters

- Groupsets

- Handlebars & extensions

- Headsets

- Hubs

- Inner tubes

- Pedals

- Quick releases & skewers

- Saddles

- Seatposts

- Stems

- Wheels

- Tyres

- Tubeless valves

- Accessories

- Accessories - misc

- Computer mounts

- Bags

- Bar ends

- Bike bags & cases

- Bottle cages

- Bottles

- Cameras

- Car racks

- Child seats

- Computers

- Glasses

- GPS units

- Helmets

- Lights - front

- Lights - rear

- Lights - sets

- Locks

- Mirrors

- Mudguards

- Racks

- Pumps & CO2 inflators

- Puncture kits

- Reflectives

- Smart watches

- Stands and racks

- Trailers

- Clothing

- Health, fitness and nutrition

- Tools and workshop

- Miscellaneous

- Buyers Guides

- Features

- Forum

- Recommends

- Podcast

TECH NEWS

DT Swiss launches endurance wheelset with Swiss Side

DT Swiss has teamed up with Swiss Side to produce the new ERC 1100 Dicut endurance wheelset that’s designed with aerodynamics, handling and stability in mind.

DT Swiss says that the ERC 1100 Dicut disc brake wheelset, with 47mm deep rims, offers very low drag at all relevant yaw angles along with comfort and reliability. The wheels are designed for use on gravel as well as tarmac.

The new wheels are the first to be developed according to what DT Swiss calls its Aero+ concept, based on drag, handling and efficiency.

“We at DT Swiss enter the desired properties of the wheel into [Swiss Side’s] software. The software then continuously alters the wheel's geometry and goes through the whole CFD calculation process with each alteration… to find the best matching geometry to the desired properties.”

The most promising geometry was then developed and eventually taken to the GST wind tunnel in Immenstaad, Germany.

“The ERC 1100 Dicut has super low drag numbers at all relevant yaw angles,” says DT Swiss. “Best of all it is right in the ballpark with the competition both when run with 25mm and 28mm tyres.”

The competition in question is the Reynolds Aero 46 and the Zipp 303 Firecrest.

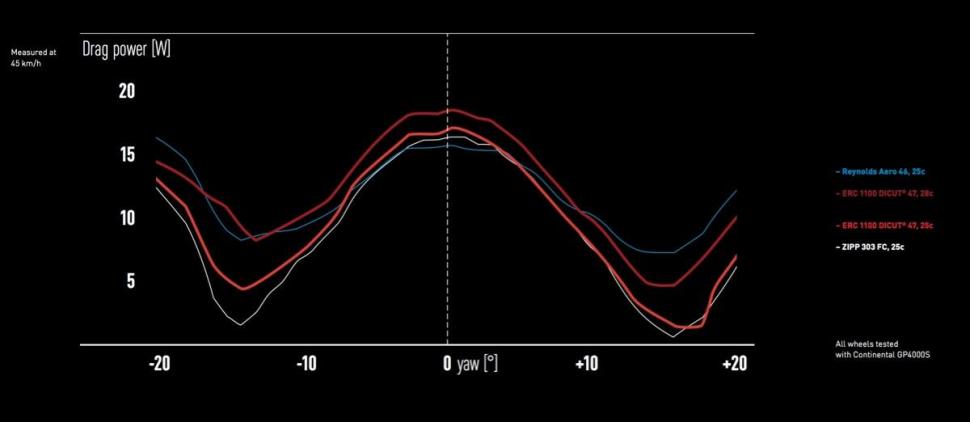

This graph shows drag power (in watts) at yaw (apparent wind) angles of -20° to +20° at 45km/h (28mph). The blue line is the Reynolds Aero 46 with a 25mm tyre, the white line is the Zipp 303 Firecrest with a 25mm tyre, the upper red line is the ERC 1100 Dicut with a 28mm tyre and the lower red line is the ERC 1100 Dicut with a 25mm tyre fitted.

As you can see, the ERC 1100 Dicut’s drag is greater than that of the competition at many points but DT Swiss says that the differences are small and that it focussed on handling and stability to gain an advantage.

“In order to stay aero in the first place, you have to stay comfy no matter the riding situation, because only then will you be able to keep an aero position,” says DT Swiss. “This is why the handling characteristics of a wheel are key.

“The ERC 1100 Dicut is the best handling wheel in wind situations commonly found on the road. This is true independent of the tyre width you chose to ride.”

DT Swiss says that the rim’s geometry means that it reacts as predictably as possible when the yaw angles change, giving the rider the chance to react and keep control of the bike. The rim shape also means that the forces generated by the wind at the handlebars are kept as low as possible, allowing the rider to hold an aero position for longer.

DT Swiss says that the ERC 1100 Dicut’s wide rims – the internal width is 19mm, the maximum external width is 27mm – have been optimised for the use of wide (28mm) tyres because the wider contact area and lower pressure of the tyre results in more grip and more comfort. Plus, a wide contact patch leads to lower rolling resistance.

The hubshell has been reshaped over that of the regular Dicut hub to minimise the airflow surface and reduce drag by 0.4 watts (at 45km/h). The hubs are based on DT Swiss 240s. They run on Sinc Ceramic bearings and are held in place by a new version of the RWS axle system with a Plug In lever that you can remove for improved aerodynamics.

The ERC 1100 Dicut db 47 – the db denoting disc brake compatibility – has 12mm axles and takes centre lock disc rotors. The rims are tubeless ready.

DT Swiss claims weights of 710g (front) and 820g (rear).

The wheels will retail at £1,999.98 when they go on sale in March 2017.

Mat has been in cycling media since 1996, on titles including BikeRadar, Total Bike, Total Mountain Bike, What Mountain Bike and Mountain Biking UK, and he has been editor of 220 Triathlon and Cycling Plus. Mat has been road.cc technical editor for over a decade, testing bikes, fettling the latest kit, and trying out the most up-to-the-minute clothing. He has won his category in Ironman UK 70.3 and finished on the podium in both marathons he has run. Mat is a Cambridge graduate who did a post-grad in magazine journalism, and he is a winner of the Cycling Media Award for Specialist Online Writer. Now over 50, he's riding road and gravel bikes most days for fun and fitness rather than training for competitions.

Latest Comments

- Rendel Harris 1 hour 52 min ago

Absolutely they could have. Tarmac is a petroleum-based product and its surface can be very oily when it's newly laid. This is particularly the...

- ROOTminus1 7 hours 54 min ago

I'm glad the article went into more detail and cleared things up, the headline had me worried that some autonomous building had run rampant and...

- mark1a 8 hours 13 min ago

Still here, just showing a few signs of wear and tear. Hopefully still serviceable for some years to come.

- Secret_squirrel 8 hours 42 min ago

Has he fully recovered though, and will he ever?...

- Rendel Harris 8 hours 57 min ago

How can you know that you are "equally fearful" as "any female cyclist"? There is no possible way of quantifying such emotions and female cyclists...

- chrisonabike 9 hours 29 min ago

I think it would be fairer to blame the moon - as in "my client is a loony".

- Bungle_52 9 hours 53 min ago

Nice idea but Gloucestershire Constabulary are not interested as exemplified by this prvious NMOTD. Not only was there NFA for the close pass in...

- hawkinspeter 11 hours 24 min ago

I think black boxes are great for early detection of cognitive decline and/or sight problems. Someone's driving is going to become much less smooth...

- Bigtwin 12 hours 32 sec ago

It's a fashion. https://guildford-dragon.com/shalford-driver-who-smashed-shalford-war-me...

Add new comment

14 comments

But whose brake pads should we use with them?

Thanks for the video link part_robot, interesting stuff. Agree with the inconsistency part. Does seem a roll of the dice on something as potentially catastrophic for personal health as a front wheel rim. On the heat build up risk in carbon rims he talks about, do we have descents long enough in the UK to get carbon rims up to these temperatures? Or is that just a risk on the longer descent off the Alps, Dolomites etc.?

under normal circumstances you'd need a good few switchbacks to get that kind of heat, but obviously, if you're forced to brake hard on any descent it will push the temperature up

Good old Chinese carbon debate again. Watch this video and all those by the same guy. https://m.youtube.com/watch?v=ET1jRVynOBA

And no, just because they are made "in the same factory to the same moulds" it absolutely does not guarantee the same layup, the same resins and the same materials. Certainly not the same warrantee. At least with a mainstream brand from an LBS you have backup if anything goes wrong.

As I always say, if you can't afford quality carbon just buy quality aluminium. Carbon for the sake of it - especially the low price stuff - is false economy and completely pointless.

5 Carbon wheel sets so far no problems, 3 sets for me (38, 50, 60mm tubulars) and 2 for a mate. Other than finding out that their bearings are crap. Which is something I change now before building my wheels. Skf abec7 if I find them otherwise abec5 at least.

My last set of wheels:

http://s32.postimg.org/8uvtek6l1/IMG_20160501_111246.jpg

I build my own wheels using chinese carbon rims. Finding a good supplier through aliexpress was a bit hard. I now build my self really good wheel sets for 400 quid. Thoses prices are outrageous.

Too pricey by far. I know what goes into making carbon products, yes they take a bit more time to produce than aluminium wheels. Not by a factor of 5. Hunt make a pair of aero carbon disc wheels and don't charge anything like these. Pays your money takes your choice

Too pricey? Too pricey for you for a set of wheels, but £2k for being at the cutting edge and having what could be the fasting wheels available doesn't sound like too pricy to me, particularly when you consider the new Zipp wheels are £3k+.

Hunt wheels are excellent, and a perfect example of that middle ground between cutting edge high end but seriously costly and the cheap and chearful but nothing like as good chinese specials. They are also a good example of tech trickle down.

What Hunt can do now is because of companies like Swiss Side and DT pushing the boundaries in the preceding years, but pushing those boundaries costs which is why stuff like these wheels cost amounts us average Joes can't justify.

So, don't knock the price just because you aren't willing to pay it.

No thank you I'll stick with my Campy Shamal Ultras.

Come on, I can buy 5 pairs of chinese wheels for the same price!

you can buy four or five decent chinese cars all at once and still have a little change from the same price of a VW GTI or Ford Focus RS, but guess which perform best.

Getting tired of the sheer number of people judging everything purely on price. The R&D and intelectual property is an important part of the price. If people stop appreciating the value of that progress will stall.

Can't justify the price of the these swiss-side/dt wheels personally, but I wouldn't buy a set of cheap no-name chinese wheels either.

I do wish though that more companies were as open as Swiss Side with regards their R&D and data release - I'm almost as fed up of companies saying 'our [insert product here] is [insert factor here] faster than the best competitor' without naming names or providing a decent spread of data to back it up, as I am of people saying 'but I can get x pairs of not anything like as good chinese copies for the same price'.

I suggest, any money they spent on R&D was wasted since they have come up with a pair of aero wheels that are less "aero" then the competition by their own figures.

As for IP being a significant part of the price, I see no patentable technology in these wheels.

What I do see, is a lot of marketing gibberish being regurgitated. Perhaps, DT's marketing dept is where the customer's money goes?

Progress? I don't think so. Unless you count new ground being broken by their marketing in bs AKA "rattling a stick in a swill bucket".

Slower than competition? On a par with Zipps for most of the yaw angle range and matching the zipps over a big part of it (but at a lower financial cost), and way better than the reynolds wheels at anything other then head on air flow.

Crucially though, if the wheels do what DT and SS state, they are much more stable, which means that you as a rider will be more comfortable and therefore able to keep the power on more effectively, and stay in the aero position more easily, meaning the 'whole system' of bike and rider will be faster.

Call that marketing bollocks if you like, but makes total sense to me. A similar analergy would be mountain bikes, or indeed larger volume tyres. They might be heavier and therefore on the face of it slower, but between the rolling resistance reduction and increased comfort, you go faster.

Are we looking at the same graph? DT Swiss are within 1W of Reynolds out to about 8deg yaw then with a max advantage of 5-6W at about 15 deg yaw (averaged left and right traces). Zipp 303 (the industry benchmark I suggest) are consistently lower drag than DT Swiss. Not sure that I'd call 303's unstable either.

Reynolds are approx £1k, DT Swiss £2k, Zipps £2 - 2.5k depending on which iteration we're talking about. Now, 5W = £1k might be an equation you're happy with, that's up to you. But others might bear in mind that's close to the level of variation arising from different brands of tyre of the same nominal size.